Vapor Polishing: An Important Guide to Plastic Parts

Feb 16,2026

Feb 16,2026

Your project needs a flawless and glossy finish on plastic parts but do not know what to do? Then vapor polishing is your thing. It is an effective method to have a smooth and transparent surface without visible surface imperfections. This article will give you more information about its work, types and step-to-step guide and many more.

What Is Vapor Polishing?

Vapor polishing is a high-precision and a chemical surface-finishing process. It is used to improve the transparency, smoothness, and aesthetics of plastic parts. The major goal of vapor finishing is to restore transparency, sealing porosity, and effective finishing of complex geometries.

Is Vapor Polishing Widely used in Industries?

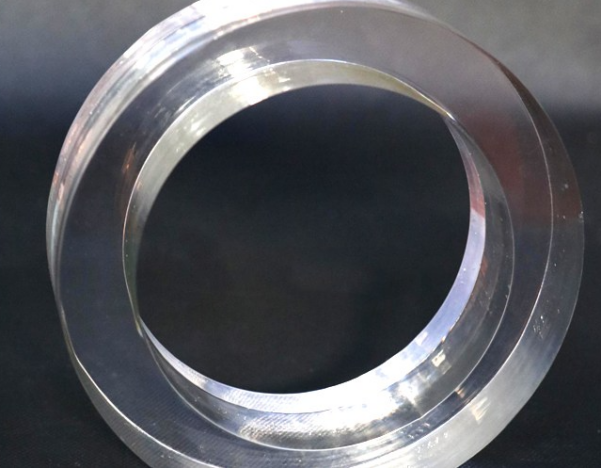

Yes, vapor polishing is widely used in industries like medical, optics and lighting, consumer products, automotive and prototyping as a typical post-processing method. It smoothens the plastic parts to obtain high-optical clarity. It is mostly applied on thermoplastics like acrylic (PMMA) or polycarbonate (PC).

Is Vapor Polishing Harmful to the Environment?

The solvents used in vapor polishing are toxic. But it is not inherently harmful to the environment when done correctly in a controlled, industrial setting. It most facilities use filtration systems to block chemical release.

What Common Materials Can Be Vapor Polished?

Vapor polishing is primarily done over amorphous thermoplastics. It gives them high-gloss and crystal-clear finishes. Before you make your parts vapor polished, you should make sure that what materials can used for vapor polishing.

Can Metal be Used for Vapor Polishing?

No, metal cannot be vapor polished in the traditional sense. This process relies on solvent vapor to soften thermoplastics. Metals are typically polished using mechanical methods like electropolishing or CVD.

Common Engineering Materials for Vapor Polishing?

Vapor polishing is applied on amorphous thermoplastics. It melts the outer microscopic layer of thermoplastic materials and creates clear surface. Common plastics can be vapor polished are Acrylic (PMMA), Polycarbonate (PC), ABS, Polyetherimide (PEI/ULTEM), and Polysulfone (PSU).

Acrylic (PMMA)

Acrylics are highly responsive to vapor polishing. They give excellent optical clarity after polishing. Vapor polishing removes surface blemishes, micro-cracks, and matte finishes caused by CNC machining.

Polycarbonate (PC)

Polycarbonate is often considered the best material for vapor polishing. Vapor polishing is highly effective at removing tool marks from machining. It also restores transparency and gives a glass-like finish.

ABS Plastic

ABS plastics are also very suitable for vapor polishing. It is considered as a standard material for vapor smoothing in additive manufacturing. Vapor finishing effectively eliminates 3D printed layer lines and seals porosity.

How Does Vapor Polishing Work?

Vapor polishing is a chemical finishing. It fills microscopic scratches and reduces surface roughness to create a high-gloss, optically clear finish. It is highly effective on complex geometries or internal features.

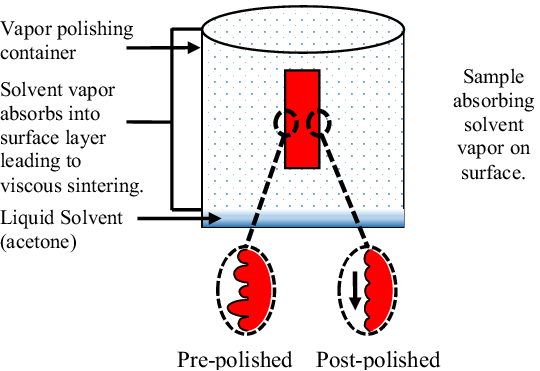

Principle of Vapor Polishing

The principle relies on controlled surface interaction. This means, a chemical solvent is heated until it vaporizes. When this vapor interacts with plastic surface, it softens the top layer. This causes a slightly liquefy or "flow," which fills in surface irregularities without removing material. When vapor evaporates, the surface re-solidifies and results in a smooth and transparent surface.

Steps of Vapor Polishing

To get the best results of vapor polishing, follow these steps:

Prepare Plastic Parts

Parts are thoroughly cleaned first to remove oil, debris, or dust. For optimal results, parts are often lightly sanded first. Because vapor polishing can only remove microscopic deformities.

Place Plastic Parts in Solvent Chamber

The cleaned parts are placed into enclosed, and often heated chamber. This chamber is designed to contain the solvent vapor.

Solvent Vapor Exposure

Solvent like acetone is heated to its boiling point around 400∘-500∘C and a dense vapor created. This vapor is either used to fill the chamber or is sprayed directly onto the part for a few seconds to a minute.

Residual Solvent Removal

When the desired smoothness is achieved, the part is removed from the chamber. Then it is placed in a controlled and ventilated area to fully evaporate the solvent. After cooling, the surface gets hardened to its final, clear state.

Types of Solvents Used in Vapor Polishing

Vapor polishing uses volatile chemical vapors. They melt and smooth the surface of plastic parts and eliminate imperfections. Common solvents for vapor smoothening are Acetone for ABS, Methylene Chloride (DCM) for PC/ABS, and Trichloroethylene (TCE) or proprietary solvents like Weldon 4 for Acrylic.

Acetone

Acetone vapor polishing is the most common solvent used and is particularly effective for ABS plastic parts. Acetone is a volatile and colorless liquid. It works well for additive manufactured ABS and lets the surface melt and solidify rapidly.

Methylene Chloride (DCM)

It is a highly potent solvent. DCM is often used for rapid, high gloss finishing on ABS parts and sometimes for Polycarbonate (PC) parts. It acts faster than acetone.

Trichloroethylene (TCE)

It is a specialized and highly reactive solvent often used to vapor polish Acrylic (PMMA) parts. It significantly enhances the optical clarity. TCE is also effective for Polycarbonate (PC) parts.

What Are the Advantages of Vapor Polishing?

Vapor polishing is also called vapor smoothing. It is highly effective for plastic parts, especially amorphous thermoplastics. The advantages of vapor polishing are:

Improved Surface Finish

Vapor smoothening transforms matte machined plastic parts into smooth and optically clear finishes. Vapor solvent slightly dissolves the outer layer of the plastic. It effectively removes 3D printing layer lines and reduces surface roughness. It also improves light transmission which is required for lenses and medical devices.

High Surface Consistency

Vapor polishing gives a highly uniform and consistent finish in complex geometries. Because it is a vapor-based process rather than a mechanical, abrasive method which provides an "isotropic" surface. It also removes the risk of inconsistent polishing or "burnt" edges often caused by manual polishing.

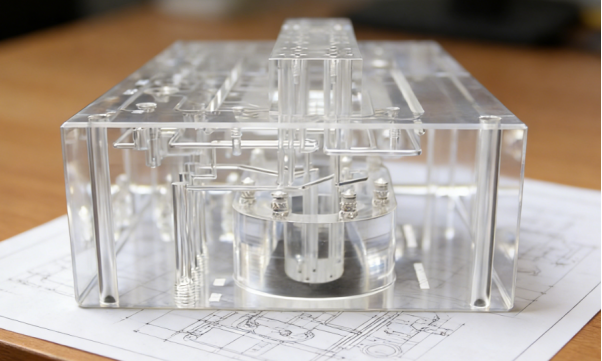

Effective for Complex Parts

vapor polishing is highly well-suited for intricate or complex-shaped plastic parts. As a non-contact process, it does not apply mechanical pressure to the parts. This prevents the deformation of delicate features.

What Are Limitations of Vapor Polishing?

As the vapor polished plastics parts have extremely smooth surface finished even after their machining. But it still has some limitations regarding materials, tolerances, and structural improvement which are like:

Limited Material Compatibility

Vapor polishing can’t be used for surface finishing metal parts for industrial applications.It is generally limited to amorphous thermoplastics like Acrylic (PMMA), Polycarbonate (PC), and Polyetherimide. Also, the parts with significant internal stresses can develop small surface cracks during the solvent exposure process.

Dimensional & Tolerance Changes

The process works by melting the outer layer of the plastic. If it is not precisely controlled, “slumping" or softening of sharp edges and fine details can occur. Even though it is designed for minimal material removal but still can cause change in thickness in tens of microns.

No Improvement for Mechanical Properties

Vapor polishing primarily acts on the top layer of the material. because it is designed to improve aesthetics, optical clarity, and rough surface. Unlike nitriding, vapor polishing cannot increase the strength or structural integrity of the part.

Applications for Vapor Polishing

As you know, vapor polishing fills in the micro-scratches, removes tool marks from CNC machining. It is very much demanded in industries like:

Medical Components

Vapor polishing improves optical clarity and sterilization capabilities on medical devices. it is mostly applied on fluidic channels to make consistent flow, on blood pumps and oxygenators to give high visibility, on surgical device housings and on sterilization trays made of polysulfone for easy cleaning. PMMA CNC medical parts are also often vapor polished for optical grade transparent surface.

Auto Parts

Vapor polishing enhances aesthetic appeal with a high-gloss finish and creates durable seals for lighting. Vapor polishing is usually applied on headlight or taillight covers of polycarbonates to maximize light transmission, on dashboard lenses and interior Trim, on air intake ducts for aerodynamic finish and on connector assemblies for better sealing capabilities.

Aerospace Components

Vapor polishing provides maximum optical transparency for viewing and reduces aerodynamic drag. It is applied on internal control system covers and on instrument panels for durability.

Consumer Products

Vapor polishing improves the visual appeal of additive manufactured or machined parts. It is mostly required for prototypes or finished products. Other than this, solvent vapor polishing is applied on electronic device housings, lighting fixtures, to improve light distribution, and on display signs.

Vapor Polishing vs Manual Polishing

Vapor polishing is generally faster and gives glass-like finish on complex, hard-to-reach areas. While manual polishing like Sanding or Buffing gives better control for small-batch or localized finishing. But it is difficult to apply consistently to intricate geometries.

|

Feature |

Vapor Polishing |

Manual Polishing |

|---|---|---|

|

Surface Finish Quality |

High-gloss and transparency. |

Good, have faint scratches or haze. |

|

Dimensional Impact |

Minimal material removal |

Higher risk of material removal and alter tolerances. |

|

Geometry Capability |

best for complex and hard-to-reach internal areas. |

Limited accessibility. Hard to polish deep pockets. |

|

Quality Consistency |

High consistency |

Low consistency |

|

Safety & Equipment |

Needs costly and ventilated equipment |

Low-cost, readily available tools |

Conclusion

Vapor polishing is a chemical treatment. It uses vaporized solvents to melt and smooth the microscopic surface layer of plastics parts. It is highly effective on amorphous thermoplastics, such as acrylic, polycarbonate, and ABS to give glossy, and transparent finish. The solvent vapor polishing is ideal for complex geometries and restores optical clarity to machined or additive manufactured parts.

Tuofa CNC service has helped customers manufacture plastic parts with complex designs for many years, any question, welcome to contact us for professional recommendations.

FAQ

What are the three types of polishing?

The primary types of industrial polishing are mechanical, chemical, and electrolytic polishing to improve roughness and give smoothness.

What is the best way to polish acrylic?

The best way for acrylic vapor polishing is to start with wet sanding with fine-grit sandpaper (600- 2000+) to remove scratches, then buffing with a polishing compound with a soft cotton wheel.

How to polish polycarbonate?

To polish polycarbonate, sand with finer grits (up to 2000-3000) then buffing with a plastic-safe polishing compound and a soft cotton wheel.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What Is Slot Milling? The Newest Guide for You in 2026

What Is Slot Milling? The Newest Guide for You in 2026