Types of Clamps by Functions, Mechanism and Materials

Oct 03,2025

Oct 03,2025

Securing components together in mechanical systems is critical in industrial and household applications. Be it an ordinary lawn pipe attached to the tap or an advanced CNC setup, clamping is important everywhere. Clamping is important in various manufacturing and construction industries like metal working, wood working, automobiles, construction etc. Let’s discuss this topic in detail.

What Is a Clamp?

A clamp is a mechanical device that holds or secures objects tightly together. Clamps in engineering application might be required for temporary holding or permanent fixture. In metal working operations clamps helps a lot in machining, welding, assembly, or repairs. Certain types of clamps are used extensively in wood working. The end use determines the type of clamps that would be used.

How Does A Clamp Work?

A clamp exerts a reasonable clamping force onto the objects that are to held securely. It happens but adjusting the moveable jaws such that both internal faces of the jaws push the objects together. The position of these jaws is actuated and kept firmly by a mechanism like screw or lever. The magnitude of clamping force that can be utilized from a clamp is the holding capacity. It depends on design, material strength and mechanism of exerting force.

Components of A Clamp

A clamp consists mainly of a frame or body that provides both space and strength, a moveable jaw that performs the gripping action and an actuation Mechanism like spring, screw or lever.

Screw, Lever, and Clamp

Screws and levers are the load generating portion while the clamp body transmits that load to the workpiece. Screws and levers are not commonly found together in a single clamping unit, though possibility still exists. Screw capitalizes up the pitch and friction of the threads. The rotating motion of the screw is converted into axial force. Even a small turning effort produces a large axial force. Lever depends on the torque and leverage principle. The length of the lever arm multiplies the input force. The screw mechanism is used in precise fastening applications while levers are used where frequent repositioning is required.

The clamp body is the structural backbone of a clamp. It transmits load from the screws or levers onto the jaws and eventually on the workpiece. The rigidity of the clamp body ensure that force is applied evenly.

What Can A Clamp Do?

Clamp is a versatile tool that is used in a number of engineering applications. Some types of clamps are used for temporary positioning. While other clamp types may be used for permanent fixture. Clamps are extensively used in metalworking, woodworking, construction, automotive, and repair industries.

Clamp Types by Function

Clamp types can be classified by their applications. While the basic function of every type of clamp remains to provide clamping force and holding capacity, they differ in designs. A clamp is designed in a such a way that it becomes suitable for a specific application. Here’s a brief overview of the broad categories of clamps.

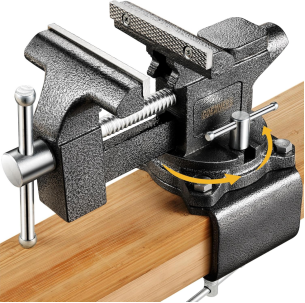

Bench Clamp

Bench clamps are mainly used for work holding in machining and welding. These types of clamps are fixed to a workbench or table. Bench clamps are commonly subjected to cutting, drilling, or grinding forces so they must be sufficiently sturdy.

Workshops, machine shops, and welding stations are the main users of bench clamps.

Edge & Joining Clamps

Edge and joining clamps are used extensively in assembly, woodworking, and furniture making. As an example, a carpenter applies glue to two wooden panels and the tightens the joining clamps. These clamps hold the wooden panels securely until the glue sets adhesively.

Hose and Tube Clamps

Hose and tube clamps are commonly used in automotive, plumbing, HVAC, and industrial clamping units. For instance, in industrial clamping units, radiators are attached with coolant pipe through hose clamps.

Clamp Types by Shape or Mechanism

Clamping systems come in various types. Each type of clamp has its own unique shape and mechanism which serves a specific application. For users, selecting a particular type of clamp is influenced by cost, ease of use and durability. The below table highlights the important features of the common types of clamps.

|

Clamp Type |

Key Feature |

Applications |

|

C Clamp |

Screw on C frame |

Heavy-duty holding |

|

F Clamp |

Sliding bar, screw jaw |

Woodworking, furniture |

|

Spring Clamp |

Spring hinge |

Light, quick hold |

|

Trigger Clamp |

Ratchet trigger |

Fast adjustments |

|

Locking Plier Clamp |

Over-center lock |

Welding, sheet metal |

|

Toggle Clamp |

Linkage lock |

Jigs, fixtures |

|

Cam Clamp |

Eccentric cam |

Quick light hold |

|

Bench Vise |

Fixed jaws, screw |

Machining, filing |

|

Parallel Jaw |

Adjustable jaws |

Large panels, cabinets |

|

Corner clamp |

Right-angle or strap |

Frames, boxes |

C Clamp and G Clamp

C clamps and G clamps have a high holding capacity due the high strength of the frame. The screw applies the pressure and the frame bears it. The heavy pressure bearing ability due to the “C” and“G” shapes are useful in demanding applications like drilling and cutting.

F Clamp and Bar Clamp

The mechanism of clamping in this type of clamp is similar to C clamps. The frame bear the load. An addition is that of sliding bar that provides extended reach. Wider jaws can hold larger workpieces. For instance, furniture assembly and holding door skins can be undertaken more easily with F clamps rather than C clamps.

Spring Clamp

The clamping force in this type of clamps is exerted by the spring. Spring clamps are lightweight, and quick to use. The shape of a spring clamp is similar to clothespin.

Trigger Clamp

Trigger clamps rely on the ratcheting mechanism. There is a slider rail on which a fixed jaw is attached on one side and a moveable jaw on the other side. The trigger handle moves the jaw step wise. Each step is locked by the rachet teeth. There is release level that can disengage the ratchet to quickly unclamp the workpiece. Due to this mechanism, it can be operated with only one hand.

Locking Plier Clamp

This type of clamp is very similar to the pliers in shape. However, the locking action provides the clamping force. An adjustable screw is rotated to make the jaws opening fit the workpiece. The lever handle can be squeezed to snap the workpiece tightly. A quick-release lever can disengage the lock to set the workpiece free.

Toggle Clamp

This type of clamp has a pivot and lever mechanism. As the lever handle is pressed it moves the linkage arms about the pivot. As the linkages cross the center point, it locks the clamping arm in position.

Cam Clamp

This type of clamps have an eccentrically or oval shaped cam. It means that one side of the cam is thicker than the other. As the cam is rotated the thicker part comes in contact with the workpiece. It’s analogous to closing of jaws.

Bench Vise

Bench vise is a permanent and heavy duty clamp that is attached to the work bench. Screw is used to tighten the jaw to hold the workpiece.

Pipe Clamp and Parallel Jaw Clamp

This type of clamps are very similar to the F clamps. There is a guiding rod and locking system that keeps the jaws parallel. Unlike the F clamps the pipe clamps apply uniform pressure across the workpiece.

Corner Clamp, Band or Strap Clamp

Corner clamps are used to set two components at a perfect right angle. The V-shaped jaws push the components such that they are perpendicular to each other.

Clamp Classification by Material

Clamps come in a variety of materials depending on the requirements of strength, durability, corrosion resistance, and cost. In some clamp types like plier clamps only a single material is used in all the components. In other types of clamps, some critical components like pads or screws can be made of materials different than the material of the body. It all depends on the suitability.

|

Material |

Strength |

Corrosion Resistance |

Weight |

Applications |

|

Carbon Steel |

High |

Low |

Heavy |

Welding, machining, fabrication |

|

Alloy Steel |

Very High |

Medium |

Heavy |

Industrial, high-stress clamping |

|

Stainless 304 |

Medium - High |

High |

Heavy |

Woodworking, general use |

|

Stainless 316 |

Medium - High |

Very High |

Heavy |

Marine, food, pharma |

|

Aluminum (6061) |

Medium |

Good |

Light |

Aerospace, portable use |

|

Polymers (TPU/Nylon) |

Low - Medium |

Excellent |

Very Light |

Crafts, delicate surfaces |

Carbon Steel and Alloy Steel

Carbon steel has a lower strength than alloy steels. Still the strength level is better than other materials like aluminum of plastics. Carbon steel and alloy steel can be an economical yet durable choice for the body of clamps.

Stainless Steel

Stainless steel is a material of choice where cleanliness and prevention of contamination is critical. Stainless steel is more expensive than plain carbon steel.

- Stainless Steel304:

Stainless steel 304 is the most commonly available grade. It is used for making clamps for industries like food processing, chemical plants, pharmaceutical etc. - Stainless Steel316:

Stainless steel 316 grade provides a more specialized corrosion protection due to its molybdenum content. Clamps made out of 316 grade are commonly used in marine environments.

Aluminum and Lightweight Alloys

Alloys like 6061 are lightweight yet having a moderate strength. Due to the low weight Aluminum prevents operator fatigue. Another advantage of aluminum alloys is of them being non-magnetic. In this way they prevent magnetic interference in electronic applications.

Polymer and Others

Pads made out of materials like TPU prevent scratches. As an example, spring clamps with TPU pads protect the painted parts against scratches or delamination during clamping.

Common Types of Hose Clamps

Hose clamps are used to connect pipes or nipples for fluid transmission. Hose clamps are of different types. The choice of hose clamp type depends on operating conditions like pressure, flow rate, temperature and reactivity.

Worm Drive Clamp

It is most common type of hose clamps. They are well suited for low to medium pressure applications. A worm screw tightens the slotted strap around a hose or pipe.

T Bolt Clamp

Although similar in shape to worm drive clamp, T bolt clamps have different applications. They can handle high pressure in applications like turbocharger systems, agricultural equipment, marine hoses, and industrial high pressure lines. The T bolt tightens the steel strap around the hose giving a uniform pressure. Unlike the worm drive clamps, T bolt clamps come in specific sizes with limited adjustability.

Spring Band Clamp

Spring band clamps are a quick to use type of hose clamps. They have small tabs or ears. As the tabs are squeezed with the pliers the diameter of the hoop increases. As he tabs are released the hoop of the spring band clamps adjusts with the diameter of the pipe. A major advantage of this type of clamps is that it can adjust its diameter itself. As an example, if the diameter of the hose changes due to thermal expansion or contraction, the spring band clamp can auto adjust its hoop diameter.

Ear Clamp

Ear clamp is a permanent and temper proof type of hose clamps. It has one or two protruding ears. These ears can be pressed to fit the hose tightly, A permanent plastic deformation occurs at the ears. So, the ear clamp cannot be released without cutting it off. As this type of clamp is vibration resistant, it is preferentially used in automotive and pneumatic applications.

V Band Clamp

V band clamp is a quick service hose clamp type for joining flanges of two pipes. The beveled edges of the mating flanges sit inside the groove of V band clamp. As it tightens it provide a good gas leakage protection. This type of clamps can be disengaged quickly without compromising the assembly. This hose clamp type is commonly used in exhaust systems, turbocharger connections, and industrial piping.

Heavy-Duty Band Clamp

This hose clamp type is suitable for handling high pressure. A wide and thick band can be tightened with clamp’s screw to adjust hoop diameter. This hose clamp type has a good strength. The wide band distribute pressure evenly to a large surface area. The are commonly used in mining and marine applications.

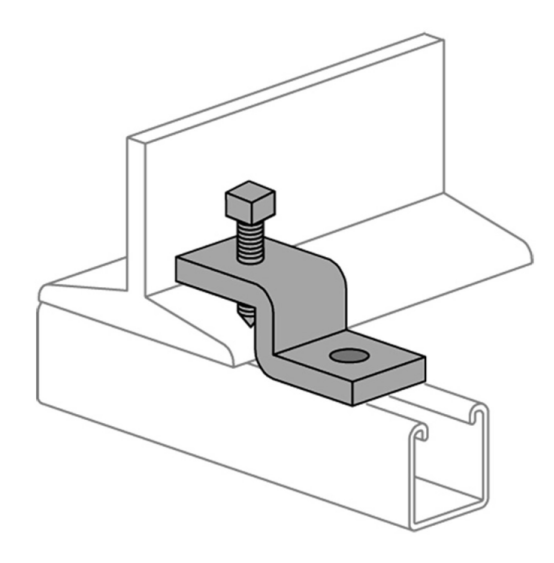

Industrial Clamping Units for Jigs and Fixtures

Industrial clamping units comes in different mechanisms for clamping depending on the applications. The requirements of clamping force, weight of objects and sturdiness dictate the type of clamps.

Manual Toggle Clamp

Manual toggle clamps rely on the linkage mechanisms. Once it moves past the center position, the clamps locks in position. It prevents accidental release during service. They are mainly used in industries where automation is not required.

Pneumatic Power Clamp

Pneumatic power clamps use compressor air to push the clamping arms. The compressed air drives the piston which applies force on the clamping arms. This force transmits to clamping pads. The whole mechanism is commonly automated. This type of clamps are used in automatic assembly lines.

Hydraulic Swing Clamp

The mechanism is similar to the pneumatic power clamps. But instead of compressed air, hydraulic mechanism drives the piston.

Pivot Clamp, Cam Action Clamp

A pivot clamp works with a rotating arm that swings into place to press the workpiece. A cam action clamp uses an eccentric cam surface that wedges tighter as it turns.

Custom Clamps: Design for Manufacturing(DFM) Tips

Custom clamps are the only option when the off the shelf clamps cannot meet requirements. Engineers design the clamps for specialized applications to improve workability. As custom clamps are designed to the specific application, all major points like clamping force, holding capacity, driving mechanism and operating conditions are considered.

When to Go Custom

When commonly available clamps cannot suffice the application’s needs, going customs becomes the only option.

Jaw Geometry and Pad Design

Jaw geometry should be such that it can holding the workpiece without damaging it. As a rule of thumb, larger surface area of jaws reduces pressure on the workpiece surface. Soft pads are preferred for delicate surfaces.

Material Choices

The choice of materials depends on factors like cost, environments, durability, strength, weight etc.

How to Manufacture Clamps

Manufacturing of clamps start with designing. Only a fool proof design can ensure accurate working. A good material selection ensures durability and affordability. A CNC machining setup is best to achieve this task. CNC gives quick and consistent results.

From CAD to CAM

Designing is done in CAD software. The CAD files are then imported into a CAM software. CAM files have the toolpaths for CNC machining. CNC machines automatically create the clamp components with repeatable results. Then these components are assembled.

Milling Clamp Bodies & Jaws

Clamp bodies and jaws are manufactured on CNC mills. They transform the blanks into final components. At first roughing removes excess material. Then contours and curvatures are made.

Turning Pins & Bushings

Pins and bushings are turned on a CNC machine to achieve the accurate diameter. Any draft can be added on the pins and bushings.

Drilling/Tapping & Reaming Seats

Drilling is done to create holes: threaded or unthreaded. Tapping ensures screw assembly.

Conclusion

Clamp is a mechanical device used to secure workpieces. Different types of clamps serve different purposes. The choice of the type of clamps depends on factors like mechanisms of clamping, clamping force, holding capacity, mechanical strength and operating conditions.

If a job cannot be accomplished with a standard clamp, going custom may be the only option. It is crucial to find a trustworthy supplier who can deliver accurate results. If you are looking for custom made clamps, feel free to share your requirements with us. Our well trained engineering team will help you to improve design and manufacture the best clamping options for you.

FAQs

What is the difference between German and American hose clamps?

German hose clamps use smooth inner bands with rolled edges for hose protection. American hose clamps use perforated bands that may bite into the hose material.

What is the difference between a C clamp and an F clamp?

Both C and F clamps rely on load bearing frame for clamping force. F clamps have a sliding bar that makes the jaw opening wider. A C clamp does not have a sliding bar.

Which is better spring clamp or worm clamp?

Both serve different purposes. A spring clamp is used in mechanically securing workpieces while a worm clamp is used for securing pipes.

What are main types of clamps in dentistry?

In dentistry, the main clamp types are winged, wingless, anterior, and posterior.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Silk Screen Printing on Metal: About How to Print on Metal Parts

Silk Screen Printing on Metal: About How to Print on Metal Parts