Industrial Rubber Rollers: Design, Materials, and Manufacturing

Aug 08,2025

Aug 08,2025

Industrial rubber rollers are the important components in steel manufacturing, textile, printing and paper industries to produce the uniform, customize hardness, reduce thickness and long-lasting layer. Due to much dependency on rubber rollers, its market is projected to grow at 4.8% in 2030 as compared to 2023. This article will discuss in detail related to the types, main components, materials, manufacturing processes, and selecting the best manufacturer of rubber industrial roller.

Typical Industrial Rubber Roller Types

Different types of custom industrial rollers are designed for different applications to get the uniformity, customize hardness and to reduce thickness of material. Most common types of custom industrial rollers are discussed below:

What are Rubber Rollers in Industrial Applications?

Industrial rubber rollers basically consist of metal core and an outer layer covered by the rubber. It basically rotates around its axis to convey the material, press and to produce the finish surface.

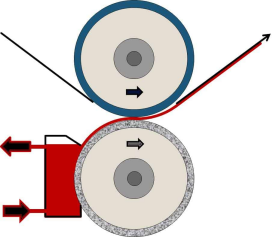

1. Nip Rollers

Nip pressure rollers consist of two rollers through which multiple sheets are passed to achieve the bonding and compressing. These rollers can be used in industries where laminating is essential like paper, plywood and textile industries.

Figure 1 Nip Rollers

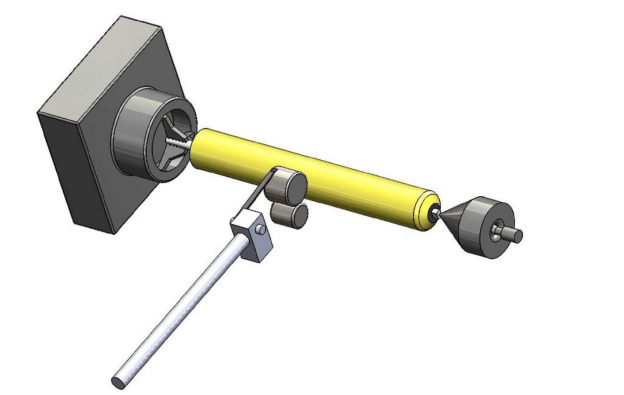

2. Drive Roller

Drive rollers are also often called Lagged drum rollers. It consists of drum and lagged rubber (outer layers) which provides the grip under heavy loads. The motor connected to conveyer to provide the primary driving force to the rollers. It is used in mining and manufacturing industries where it is gripping (between roller and belt) and transportation of goods in production line is important.

Figure 2 Drive rollers

3. Idler Rollers

Idler Rollers basically usage the weight of the rollers (without motor) to reduce friction, balance and alignment. Idler rollers consist of small cylindrical rollers that join, and they are made up by rubber coating steel or aluminum, HDPE materials. It is used in textile machines and paper mills due to its efficient and smooth transportation of the material.

Figure 3 Idler rollers

4. Spreader Rollers

Spreader rollers consist of slight curve roller like shape of banana that is why they are also called the bow or banana rollers. This shape basically provides the tensions across the width to eliminate the misalignment, folds in paper, fabric and packaging industries.

5. Anilox Rollers

Anilox rollers are mainly used for flexographic printing. In this roller, basically consists of millions of tiny, engraved cells which hold and deliver the ink for printing in a controlled amount.

6. Vacuum Roller

Vacuum roller holds and transports lightweight materials to use in thin films or paper sheets. It consists of metal rolls with perforated rubber coating holes and core is connected to the vacuum to transport the material.

Core Components of a Rubber Roller

Core components of custom industrial rubber rollers consist of metal core, rubber covering and end shaft. Every element/part in rubber roller plays a critical role in achieving uniformity, surface finishing. The key elements of rubber roller are discussed in detail below:

Roller Core: Shaft, Cylinder, Flange

The roller core is key component in the rubber roller to ensure the torque transfer (to the material) and alignment. Roller core has three parts which are shaft, cylinder and flange.

1.Shaft in Rubber Rollers

Shaft basically connects with motor to transfer the torque to the materials to maintain the pressure on the material.

2.Cylinder in Rubber Rollers

Cylinder is the hollow tube which acts as base to apply coating on it.

3.Flange in Rubber Rollers

A flange is a rim or collar that connects with the shaft for mechanical support.

Bearing Selection and Mounting

Proper Mounting selection leads to reduces vibration and greater life cycle of rollers. Bearing is used to support the rotating shaft. Both pillow-block and journal bearing support the shaft but have different designs. Difference in pillow-block and journal bearings is discussed below in table-1:

Table-1: Advantages and limitations of different bearings

|

Bearing type |

Advantages |

Limitations |

|

Pillow Block |

Easy to install and maintain |

Limited loads bearing and speed, High friction |

|

Journal Bearings |

Handle high loads and speeds, low friction |

More lubrication needed, complex installation and maintenance |

Rubber Cover and Bonding Layer

Rubber cover is the outer layer after cylindrical roller. It directly connects with the material which is being pressed. Bonding layer provides the adhesion between the rubber and metal core. It involves Shot blasting (surface roughing) and then applying the adhesive primers (Silane-based for silicone rubber) /under-layers to get the more adhesion of rubber with core metal.

End Caps and Seals

End Caps and Seals is first line defender against the contamination; leakage and it is attached to the end of roller. Different types of seals used in rollers are discussed below in table-2:

Table-2: Different types of seals used roller with their efficiency, temperature and cost range

|

Type |

Sealing Efficiency |

Temp Range |

Cost |

|

Lip Seals |

85-95% |

-40°C to +120°C |

$ 5-50 |

|

Labyrinth Seals |

97-99% |

-50°C to 200°C |

$ 20-100 |

|

Magnetic Seals |

100% (leak free) |

-100°C to +260°C |

$ 7-35 |

Common Materials for Industrial Rubber Rollers

Selection of appropriate rubber material in rubber roller is necessary to ensure the quality of product. Following table shows the common materials and their functions used for custom industrial rubber rollers:

Rubber Materials List

Table-3: Most common rubber materials with their properties and functions

|

Material |

Key properties |

Functions |

|

Natural Rubber |

High elastic material and excellent shock absorption |

Conveyor rollers, printing rollers |

|

Nitrile |

Excellent resistance to Oils and chemicals, good abrasion resistance, puncture resistance |

Automotive, industrial machinery |

|

Polyurethane |

High hardness, durability and good adhesion with materials |

Heavy-duty conveyors, coating, sports equipment |

|

Silicone |

Thermal stability/resistant, resistant to moisture |

Seals and gaskets used in oil and gas industry, Food processing, medical rollers |

|

EPDM (Ethylene Propylene Diene Monomer) |

Provides the Weather, temperature and UV radiation resistance |

Outdoor conveyors, construction industry |

Matching Rubber to Line Conditions

The right choice of rubber is necessary to withstand the operating condition in production line to avoid the low life cycle and slippage of roller. For chemical exposure, Nitrile (NBR) and EPDM are preferred to use in the oil and acid/Alkalis system respectively. HDPM and silicone rubber rollers are preferred to be used in a high (<250°C) and moderate range (80-120°C). For excellent grip properties (High traction coefficient), natural rubber is preferred to be used. To get smooth and less sticky surface (low traction coefficient), silicone and polished NBR is preferred to be used.

Common Roller Core Material Selections

Roller core is the main component of roller because it provides the strength to roller and withstand the operational load. Different materials are used for different applications; some common core materials are discussed below:

Carbon Steel Roller Cores

1045 carbon steel is the most common used material for roller cores and roller shaft due to its cost effectiveness, easily available, high strength and durability. 1045 carbon steel rollers are commonly used in the printing press and in conveying rollers.

Stainless Steel Roller Cores

Stainless steel rollers cores and shafts are commonly used in the environment where operating conditions are more acidic and exposure to chemicals. 304 and 316 grade is the most common stainless steel used for these operating conditions. 304 is commonly used in low harsh environments where ductility is important. While 316 stainless steels used for extreme chloride conditions due to presence of molybdenum.

Aluminum Alloy Roller Cores

Aluminum alloy rollers cores and shaft are mostly used for weight reduction and to maintain structural integrity. 6061-T6 is most used material for roller core and shaft due to lighter in weight about 1/3rd weight of steel, excellent machinability, moderate strength.

Lightweight Composite Roller Cores

Carbon fiber and glass fiber reinforced polymers are most commons fibers used for composite rollers cores. It is mostly used in the high-speed conveyor systems, semiconductors equipment due to its light weight and corrosion resistance.

Rubber Rollers Manufacturing Process Step-by-Step

Industrial rubber rollers manufacturing and machining are discussed in detail below:

Roller Core Machining Processing

Machining is the most important step in the manufacturing of rubber roller because its structural integrity and alignment are decided based on the machining process. Here is the step-by-step machining process that is discussed below:

- Step 1: Material Preparation

Select the material according to application and then cut the material.

- Step 2: Rough Turning

In rough turning, extra material (irregularities) is removed through lathe machine by allowing some allowance.

- Step 3: Face Milling

In face milling, a cutter cuts the end face of shaft to ensure the smooth, accurate and flat surface.

- Step 4: Center Drilling

In center drilling, holes are drilled on both ends of the core to provide the adequate support during the turning process. Size of hole should be sufficient to avoid the back-and-forth movement of workpiece.

- Step 5: Finish Turning

Finishing turning is the last step for machining process and it is then ready for the rubber insertion. In finishing turning, exact dimensions of rollers are achieved with some tolerance. It is done by movement of grinding tool and roller in parallel direction.

- Step-6: Inspection & surface preparation

Inspection is done after the finishing process to ensure the quality of roller. Sandblasting or chemical treatment can be done to improve adhesion of rubber with metal.

Rubber Compounding and Mixing

Rubber compound can be synthetic or natural and it is mixed with fillers, additives, antioxidants. It is then homogenized through Banbury mixer.

Cover Building: Plying, Extrusion, Casting

In rubber covered roller, rubber can be covered on the metal core roll by the hand-ply winding or extrusion wrap. In hand-ply winding, rubber sheet is covered on the metal core manually by hand. In extrusion wrap, rubber is extruded through die and then wrapped on the metal core to get the rubber roller covered. Casting is mostly used for the urethane-based rollers in which liquid rubber is poured around the metal core.

Vulcanization and Controlled Cooling

Once the rubber is applied on the metal core, vulcanization (heat curing process) is done to ensure the proper linking of rubber molecules.

Precision Finishing: Grinding, Crowning, Grooving

For precision rubber rollers, finishing is the most important step for the manufacturing of rubber rollers. It enhances the rollers life cycle, durability, and prevents the roller from material deformation. Precision rubber rollers finishing reduces the uneven wear and coating in conveyer system.

When to Use Different Types of Industrial Rubber Rollers?

Different types of industrial rubber rollers are designed according to different operating conditions and applications. Some rollers applications are discussed below:

Printing and Graphic Arts Rollers

Printing and graphic rollers used in the printing industry to provides the uniform ink transfer, dimensional stability and heat stability under repeated cycles.

Conveyor Drive and Idler Rollers

Conveyer drive and Idler rollers can be used in the mining, agriculture industry to transport the items. Durable and abrasion resistance materials are used for this application.

Food-Grade and Sanitary Rollers

Food grade and sanitary rollers hygiene standards due to direct contact with rollers. These rollers are used in the pharmaceutical, beverage and food processing industry. FDA-Compliant Silicone rubber rollers can be used for these applications due to being non-reactive, and easy to sanitize.

High-Temperature Silicone rubber Rollers

Silicone rubber rollers can be in textile, plastic, printing circuit board industry due to their resistance to withstanding the heat more than 200°C.

What are the Surface Coatings and Textures

Surface coating and texture increase the traction required for the conveying. A textured surface improves grip and sticking as compared to smooth surface.

Rubber vs. Polyurethane Spray Coatings

Coating material like Rubber provides the better resistance to elastic deformation and toughness. Polyurethane coating provides more resistance to abrasion and can bear the high load which is necessary in conveyors.

Rubber Roller Textures

Textures increases the adhesion and reduces the material buildup on the roller.

- Groove Patterns- Used for printing, food processing industry due to helps channel ink and improve traction.

- Herringbone Patterns- Used in conveyors to guide material and minimizing slippage.

- Diamond Patterns- Used in heavy load industry due to its aggressive grip.

Mounting Systems for Industrial Rubber Rollers: CNC Machined Solutions

CNC machine ensuring the alignment, provides the precision rubber roller, reduce machining time which is the basic requirement for the modern machining of industrial rubber roller.

CNC Machined Mounting Brackets

CNC machined mounting brackets are produce through the milling, turning feature of CNC. CNC provides precision mounting (ensure alignment, prevent wobble), very tight tolerances and can make complex shapes for heavy load applications with high quality.

Anodized CNC Aluminum vs Painted Steel

There are two common materials choices for the CNC machining. One is anodizing aluminum, which is cost effective, lightweight and can be used food, chemical industry. Second common choice material is painted steel which has high load bearing capacity and can be used in mining and construction industry.

How to Select Rubber Roller Manufacturers?

Manufacturers of rubber rollers can be dependent on the application/properties required. Here are the key factors in selecting the rubber roller manufacturers:

Quality Certifications and Testing Capabilities

The first capability that should be considered, while choosing a rubber roller manufacturer is, if the manufacturer has acquired any certifications about the quality of materials and their testing capability. Here at TUOFA precision machining, we have ISO 9001 certified machining services. These procedures help us in adhering to strict quality standards. We at TUOFA, also provide dynamic balance report signifying our product quality and how our products are prevented from vibrations and wear and tear during high-speed rollers.

Custom Engineering Support

The best custom rubber roller manufacturers offer the complete guidelines for material selection, properties require for specific applications. At TUOFA, we not only understand the customers’ requirements, but we also provide with solutions and guidelines to best suit our customers.

Lead Times, MOQ, and Cost Drivers

The best custom rubber roller manufacturers provide the 3-6 weeks lead time and MOQ (minimum order quantity) is one. The best cost drivers are the material, precision tolerance and coating/texturing. The customers of TUOFA, receive detailed inspection reports, appearance checks and information before shipping. This helps in lowering the overall cost for our customers, as they receive only the best quality products that are built and have been tested according to global standards.

Conclusion

Industrial rubber rollers are the critical component that requires to design it, select appropriate material, production, machining. Different types of materials are used according to different operating conditions. Turning and milling is the most important step to maintain the quality of rubber roller during machining. Surface coating and texture increase the traction required for the conveying. The best rubber manufacturer can be evaluated by asking for certificate and comparison of cost, technical parameters.

FAQs on Industrial Rubber Rollers

What are the disadvantages of rubber rollers?

Rubber rollers can degrade and reduce life cycle due to exposure in a harsh environment (temperature, chemicals, UV light).

What is the best material for rollers?

The best material for industrial rubber rollers depends on the application. NBR is ideal for printing, automotive industry, on the other hand EPDM is ideal for outdoor conveyors.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What Is a Pipe Nipple? A Complete Guide to Types, Materials, and Machining

What Is a Pipe Nipple? A Complete Guide to Types, Materials, and Machining