How to Remove a Broken Tap: Something You Must Know

Oct 02,2025

Oct 02,2025

Fasteners with threaded joints are one of the common features in mechanical assemblies. Internal threads need a tap that can be easily damaged if not taken care of. But to make it functional, you must know how to remove a broken tap. This article will help you understand what the common ways to remove a broken tap and to keep the damage minimum.

What Is a Tap in Machining?

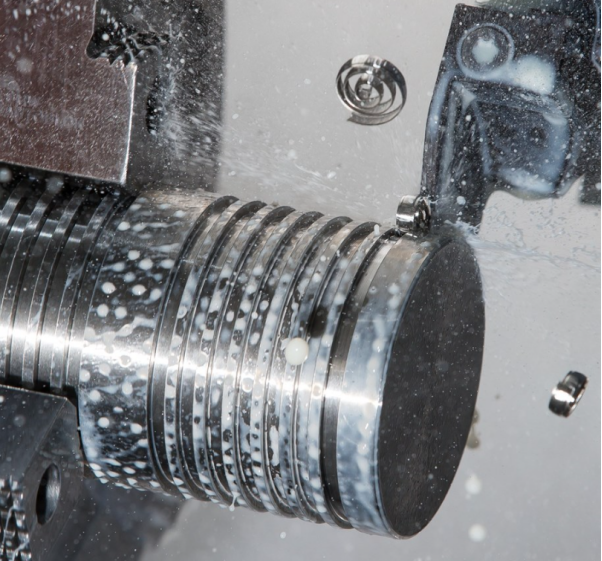

Tap is a tool in machining to cut or make internal screw thread inside a drilling hole. The process is called tapping and it is essential to create threads that can attach with fasteners like bolts or screws. Taps can work manually with a tap wrench or by a CNC machine or drill press.

Tap Types and Thread Forms

There are different types of taps depending on the material and hole types.

- Hand taps: available in set of three (taper, plug, and bottoming) for manual tapping.

- Machine Taps:use with machine tools and make the entire thread in a single pass. Examples are: spiral point taps, spiral flute taps and thread forming taps

Some common threads standards are:

|

Standard |

Description |

Application |

|

Metric (M) |

international standard for general-purpose screw threads. |

used for general assembly. |

|

Unified National Coarse (UNC) |

general-purpose coarse thread in USA having s a deep, rounded profile |

General assembly in iron and softer metals. |

|

Unified National Fine (UNF) |

Fine thread form in USA having a stronger tension and cannot loosen from vibration. |

Precision applications, and thin-walled materials. |

|

Unified National (UN) |

A constant-pitch thread series used but does not fit into the standard UNC or UNF series. |

Custom or specific engineering applications. |

|

National Pipe Taper (NPT) |

Used for pipes and fittings to create a liquid-tight seal. |

Plumbing, and other sealed connections. |

Common Tap Materials

Commonly used tap materials are HSS, cobalt and carbide. HSS is the most affordable but has least hard among all. It is tougher and less brittle than carbide and has applications for general purpose tapping.

Cobalt is harder and more wear-resistant than HSS.it has excellent high-temperature resistance and less brittle than carbide. It has applications with harder materials like stainless steel and titanium.

Carbide is the hardest and most durable, but also the most brittle. It is expensive and used for High-speed and high-volume production in abrasive materials like hard steel and composites.

What Are Common Tap Hole Types?

Tap holes are categorized by the length of their pass like if they completely go through the workpiece or not.

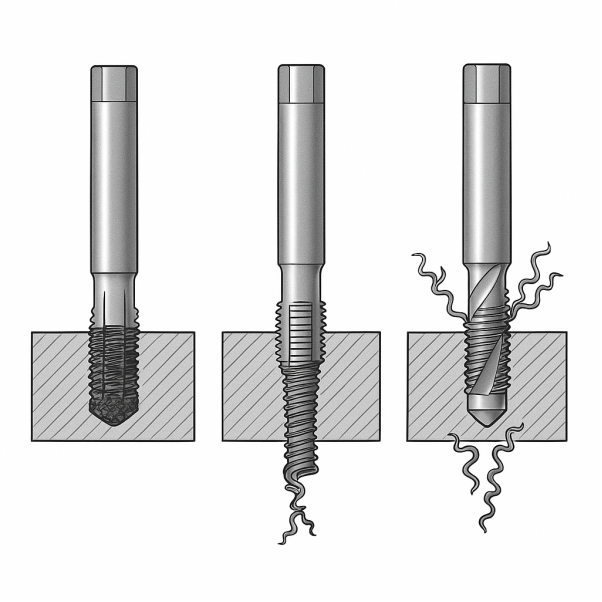

Through Hole vs Blind Hole

A threaded through hole is a hole that passed completely through the workpiece from one to the other side. It is easier and chips can exit the hole from the bottom.

A threaded blind hole goes to a certain depth and does not pass all the way through the workpiece. Chips are difficult to remove from holes to avoid binding and chips breaking.

Why Taps Break so Easily?

Tap and hole break easily because they are brittle and hard. They are designed to cut internal threads by shearing and not bending the metal. This rigidity makes them prone to breaking under different stresses.

Incorrect Pilot Hole

Pilot hole diameter must match precisely to the tap size and threaded material. incorrect size increases the risks of breaking. In undersized holes, small forces remove too much material which increases cutting resistance and torque more than tap’s capacity. And oversized holes are too large and do not give threads enough material to grip.

Misalignment or Sync Error

If tap is not aligned with the pilot hole or feed rate is not synced with the spindle rotation, it breaks the tap. Misalignment causes uneven force distribution and sync error generates stress in reversal cycle which breaks the tap.

Chip Packing or Poor Lubrication

In blind holes, chips are packed into the tap’s flute and clogged them and increase the torque to risky level. And lubrication reduces friction and heat which can cause tool wear and breakage.

Worn Tool or Wrong Geometry

Worn or dull tap and hole needs more cutting forces which increases torque and heat. It can make tap brittle, and tap can snap under stress. Wrong geometry are wrong flute designs for hole type or wrong tap for the material.

Before Removing Taps from Holes

The removal process of broken tap during threaded operation must be done carefully to avoid damage. Broken tap is harder than material so standard drill cannot be used. Follow these steps to successfully for tap removal

Identify Hole Type and Access

Identify the hole like it is blind hole or a through-hole. Then check the distance from the surface and if it is possible to grip it with a small wrench or pliers. If it is broken off flush, you need different approach. Clear the chips and debris and apply penetration lubricant.

Consider Workpiece Material

Know the workpiece material because there is a different technique for hard material and for soft material.

How to Remove Broken Tap from Aluminum

Al has low melting point and heating methods can damage the workpiece. Use tap extractor or chemical tap remover like "Tap-X Broken Tap Removal Kit". Alum baths can also be used but it is a slow process.

Removing Broken Tap from Steel

Steel has high melting points so aggressive methods can also be used. Tap extractor, shock and vibration, welding, electrical discharge machining (EDM) and carbide drill and grinding can be used.

Gauge Tap Size and Exposure

Tap’s size and its exposure help to decide the removal strategy. Larger taps break of ¼-20 and are easier to remove while smaller taps are difficult to remove without damaging the threads.

What is The Best Way to Remove a Broken Tap?

The best way of tap removal depends on the size of the tap, the workpiece material and the depth of broken tap. Tap extractor can be used for a clean break. But other methods like drilling and Electric Discharge Machining (EDM) machine are sometime necessary.

Back Out the Tap with a Left-Hand Drill

A reverse-cutting drill bit is used to try and catch the broken tap and unscrew it. Workpiece is held tightly, and a center punch is used to create a divot close to the center of broken tip by a left-hand drill. Drill moves in reverse direction, and it loosens the tap and then it spins out the hole

Cut a Slot to Unwind the Stub

A small slot provides a purchase for a screwdriver to back the tap out of the broken tap near to the surface. A rotary tool cuts a slot, and lubricant is applied to loosen the tap.

Core Out the Tap with a Solid Carbide Drill

Drilling with a solid carbide drill is aggressive option. grinder flattens the top of broken tap to have a stable surface for drilling. Slow and consistent feed rate with high RPMs cuts the hardened tap and the remaining pieces are removed from thread.

Which Tool Is Used to Remove a Broken Tap from a Hole?

Tap extractor is the common tool to remove the broken tap. It has hard steel fingers that fit into the flute of tap. Reverse torque is applied, and broken pieces are unscrewed without damaging the surroundings.

Choose 2-Flute or 4-Flute

The number of flutes on the extractor and the number of flutes must be same n the broken tap. 2-flute extractor is best for taps used on softer metals like aluminum or for roughing applications. 4-flute extractor is best for taps used on harder materials like stainless steel, and cast iron

Seat Fingers on Flutes

Tool’s collar is slide or sleeved down until it rests against the work surface. This locks the fingers into position and prevents them from expanding and jamming.

Apply Controlled Reverse Torque

Tap wrench on the square end of the extractor is used to apply controlled reverse torque. Tap is then twisted back and forth gently at first to get loosened and continue turning counterclockwise until it backs out of the hole.

Non-Mechanical and EDM Methods

Non-mechanical and Electrical Discharge Machining (EDM) methods are also effective for removing broken taps, especially when conventional tools are failed.

1.TIG Weld a Nut

It is used to remove steel broken taps that are below the surface or are broken flush off with. A washer is placed on the workpiece to protect the surroundings and nut over the washer is placed. TIG welder is used, and center of the nut is filled with weld to fuse and to break the bolt. After cooling, broken tap is removed.

2.Thermal Cycling

It used repeated heating and cooling cycles to loosen a seized fastener. Heat is applied to the workpiece and as the outer part expands, a small gap is created between threads and tap. The expansion and contraction cycles opens a path for penetrating oil.

3.Alum Dissolution

It is a chemical method and is ideal for non-ferrous parts, like aluminum or brass. A saturated solution of potassium aluminum sulfate (alum) in hot water is created, and workpiece is placed in it. Heat the solution which causes the steel to dissolve over a period.

4.EDM Hole-Popper

EDM uses an electrode to erode a hole through the center of a broken fastener. A spinning electrode is positioned over the broken fastener which is submerged in a dielectric fluid. Electric current is passed between the electrode and tap, and sparks erode away the material.

How to Restore the Thread After Removal

After the removal of threads, there are several methods that can restore these threads depending on the damage.

Chase or Re-Tap

It is an effective method for less damaged threads. A chaser is the least aggressive tool for cleaning up threads. Or if the threads are lightly damaged, a tap or re-taping can run through the hole to clean and straighten them.

Helicoil or Keysert

These are threaded inserts used when the original threads are stripped or cross-threaded. Helicoil uses a stainless-steel wire coil to replace the old threads. damage threads are drilled out and new oversized threads are cut in the hole. Helicoil is inserted into the hole and tang is broken off at the end of coil.

Keyserts are solid metal bushings with internal threads and external threads. They have "keys" on outer and are hammered in after installation to lock the insert in place.

Oversize and Re-Tap

If there is enough material to support a larger fastener, damaged hole can be drilled out and can be tapped for the next size up

Tips for Creating Internal Threads Without Breaking Taps

There are few tips that must be kept in mind when creating internal threads to avoid damage.

Choose the Correct Pilot Hole Size

Always use the correct drill size for tapping to have a right thread percentage

Chamfer the Hole Entry

Make a lead-in chamfer on the hole entrances to help the tap and to reduce the starting torque. If tap running is difficult, this shows excessive torque and a high risk of breakage.

Select Tap Geometry for the Material

Choose the right type of tap and material. Use form taps (cold-forming taps) for softer materials and straight flute taps for brittle materials. Use taps made of cobalt steel (HSS-Co) or solid carbide.

Manage Chip Evacuation

Clogged chips or chips stuck in the hole can cause tap breakage. Optimize the coolant strategy to manage chip evacuation. Use high-pressure and through-spindle coolant with generous flooding.

Or there is another helpful choice: come to TUOFA CNC Machining shop. With nearly 20 years of experience in the precision custom machining industry, we have extensive experience in turning, milling, and tapping. We can ensure maximum precision and consistency, minimizing broken taps caused by technical issues.

Conclusion

One of the safest and most common ways for tap removal is by using a specialized tool, Tap extractor. It has a finger that fits into the tap's flutes to twist it out. Other ways for tap removal are welding a nut, using chemical solvents, or drilling, but these can be risky. The best selection of tool for removing taps depends on the size of the tap and its depth.

FAQs

How to remove a broken threaded fitting?

Insert the right size tool into the broken thread and turn counterclockwise to remove it.

How do you remove a broken tap from a blind hole?

Clean the hole and then attempt extraction with tap extractor or a screw extractor and turn counterclockwise

How to remove snapped thread?

Use a hacksaw and cut a horizontal line in the bit that sticks out and then use screwdriver to remove it.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Types of Clamps by Functions, Mechanism and Materials

Types of Clamps by Functions, Mechanism and Materials