Things You Need to Know about CNC Kovar Machining

Jun 10,2025

Jun 10,2025

Here we are going talking about Kovar alloy today. Kovar is a material or alloy that we use to tackle issues like thermal expansion in critical applications efficiently. This article presents you with quality content about what Kovar Alloy is, its compositions, its applications and many other aspects of this interesting material. So, let’s begin with what Kovar alloy is:

Kovar Alloy

Kovar metal, greyish silver colour, is a Fe-Co-Ni alloy which is made in a vacuum. Its chemical composition is controlled with very narrow limits to make it the best material for issues like thermal expansion. Its coefficient of thermal expansion is the same as that of borosilicate glass.

Kovar Composition

The chemical composition of any metal is the key to super or bad mechanical properties. First, the Kovar alloy is manufactured in a vacuum, and then its chemical composition is controlled in very narrow and strict limits. Overall, Kovar is a Fe-Co-Ni alloy with the following weight percents of each element:

|

Element |

Weight Percentage (%) |

Role in the Alloy |

|

Iron (Fe) |

54% |

Base metal provides structural strength. |

|

Nickel (Ni) |

29% |

Controls thermal expansion to match glass/ceramics. |

|

Cobalt (Co) |

17% |

Enhances thermal stability and magnetic properties. |

|

Manganese (Mn) |

≤0.50% |

Improves machinability and deoxidation. |

|

Silicon (Si) |

≤0.20% |

Reduces oxidation during melting. |

|

Carbon (C) |

≤0.02% |

Minimises brittleness. |

|

Sulfur (S) |

≤0.02% |

Prevents hot cracking. |

The table shows the role of each alloying element. Why Kovar metal is best for the thermal expansion issue is the Ni and Co elements.

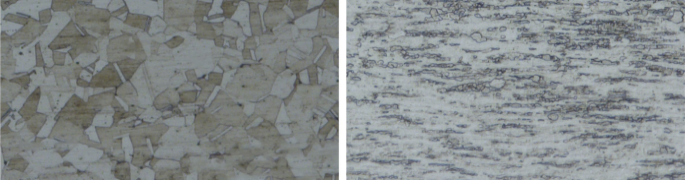

Microstructure of Kovar Alloy

The microstructure of Kovar material is a fine-grained structure. This microstructure provides strength, fatigue resistance and makes it able to be used in precision parts such as RF packages. These are the following micrographs:

Thermal Expansion Match

As mentioned earlier, the thermal expansion of Kovar material is almost equal to borosilicate glass, i.e. 5.1 × 10⁻⁶/°C from 30-200°C. It prevents seal failures in the electrical housing.

Corrosion Resistance

It's generally suitable for elevated temperature applications, i.e. <400oC. You can use passivation or coatings to use in harsh conditions.

Why Engineers Choose Kovar for Machined Parts

Kovar is an interesting material due to its precisely controlled chemical composition and vacuum manufacturing. Let’s study in this section why engineers choose this material specifically.

Hermetic Sealing

Low thermal expansion property enables the Kovar material for glass-to-metal seals. For instance, in the application, high-voltage feed-throughs in MRI machines, a leak rate of <1 × 10⁸ atm·cc/s is required. Thermal expansion of Kovar material ~5.1 × 10⁻⁶/°C prevents cracking under thermal cycling.

Magnetic Properties

Kovar alloy has a magnetic permeability of ~2,000 μᵣ, which you can further adjust via heat treatment. It is used as a magnetic shield in MRI housing. It exhibits controlled magnetic permeability.

Temperature Stability

The dimensional stability of Kovar material is good even at high temperatures. Kovar seals are used in nuclear reactors and remain intact in heat and radiation.

Machinability Challenges of Kovar

Kovar machining sometimes becomes a challenge for machine operators. Although Kovar provides exceptional thermal expansion, Kovar's machinability is difficult, as you will see in this section:

Work-Hardening & Built-Up Edge

When you apply stress to the Kovar metal, the work-hardening phenomenon occurs, and it becomes harder. It results in tool wear and causes a built-up edge. This problem results in two major defects:

- Poor surface finish

- More tool changes, so higher costs

- You can fix this problem using sharp carbide tools, avoiding dwell, etc.

Diffusion Tool Wear

During Kovar machining, due to high temperatures, cobalt diffuses into the workpiece from the tool wear. It results in premature failure and increased machining time.

- You can use diamond-coated tools because they resist diffusion. Further, you can use slow machining speeds.

Coolant Selection

When you use inadequate coolants, it leads to chip welding and tool damage. It results in poor part tolerance and scrapped components. You can resolve this issue by using high-pressure coolants.

Kovar CNC Machining Processes

Due to unique properties, Kovar requires advanced machining. That’s why we do precision Kovar CNC machining. You can study different CNC operations in this section, which are performed on Kovar.

Precision Kovar Turning

The turning operation is performed on cylindrical components of Kovar material. These are the benefits of using turning operation for Kovar material:

Benefits:

- You can achieve a tight tolerance up to ±0.005 mm for cylindrical parts

- Excellent surface finish can be achieved up to 0.5Ra

- Cost-effective high production for seals

On the downsides:

There are some disadvantages as well to performing CNC turning operations on Kovar material. Such as

- If the design of your part is difficult, then you will have to use post-turning processes as well.

- Due to the work-hardening feature of Kovar, you should use sharp carbide tools.

Five-Axis Kovar Milling

Five-axis means that CNC tools can precisely work across the five axes of the Kovar parts. It is good to use for intricate designs. These are the advantages of Five-axis Kovar Milling:

Advantages:

- Difficult designs of parts, such as aerospace housings, can be easily machined in a single setup.

- Good accuracy even with low radial depth, i.e. ≤10% tool diameter. It helps with the reduction of chip welding.

However:

However, there are some downsides to Five-axis Kovar Milling:

- It's expensive because of higher machining and tooling costs.

- It requires a high level of programming to run this machine.

EDM & Wire-Cut Kovar

If you need delicate cuts in your Kovar material parts, then you can use Electrical Discharge Machining for hardened parts.

Advantages:

- Since there is no mechanical stress in this machining, you can use it for harder materials as well.

- You can use EDM & wire cutting for parts like micro-fluidic channels, which need intricate cuts.

Disadvantages:

The disadvantages of using EDM & wire cutting for Kovar material include:

- In the case of high-volume productions, it is not suitable.

- Higher energy consumption and electrode costs increase the price of the parts.

Micro-Drilling Kovar

The drilling process is used to make holes in the parts for medical and electronic components. The micro-drilling can provide you with precise holes of <1 mm tolerance.

Benefits:

- It achieves high aspect ratios, for instance, 10:1 depth-to-diameter, with minimal deflection.

- Important process for surgical device ports.

Disadvantages:

The disadvantages are:

- Rapid tool wear increases maintenance costs.

- Chips are difficult to evacuate. You can use peck-drilling or high-pressure coolant.

How to Better Machine Kovar Alloy?

As you know already, Kovar is a difficult material due to its hardening feature and surface abrasiveness. So, you must machine this material very carefully. These are some parameters which are essential while machining Kovar alloy.

Tip 1: Choosing the right tools

There are two types of cutting tools which are common in machining the components, i.e. High-speed steel and Carbide tools.

- HSS vs. Carbide Tooling

The following table covers all the important points related to these cutting tools:

|

Factor |

HSS Tools |

Carbide Tools (Recommended) |

|

Tool Life |

3-5× shorter lifespan |

5-10× longer vs. HSS |

|

Cutting Speed |

Limited to ≤60 m/min |

Optimised for 80-200 m/min |

|

Work-Hardening Risk |

Higher (dull edges exacerbate hardening) |

Lower (maintains sharpness longer) |

|

Cost |

Lower upfront cost ($10-$50/tool) |

Higher ($50-$200/tool) but cost-effective long-term |

|

Best For |

Prototypes, low-volume jobs |

Production runs, tight-tolerance parts |

|

Coatings |

Rarely coated; less heat resistance |

TiAlN/AlCrN coatings reduce heat by 30% |

Tip 2: Starter Speeds and Feeds

When you use balanced starter speeds and feeds, you can prevent work-hardening and tool wear.

For a Ø10 mm TiAlN-coated carbide end mill in annealed Kovar:

|

Operation |

Speed (m/min) |

Feed (mm/tooth) |

Depth of Cut (mm) |

|

Roughing |

80-100 |

0.08-0.12 |

1.5-2.0 |

|

Finishing |

120-150 |

0.03-0.05 |

0.2-0.5 |

Tip 3: High-Pressure Coolants

There is another issue with Kovar machining: it retains heat during machining. It doesn’t allow heat to pass through it. So, these are the recommendations:

- Use a coolant of high-pressure coolant with 1000-1450 psi (70-100 bar) with a ≥15 L/min flow rate.

- Use a synthetic coolant.

- These recommendations can be helpful in flushing chips efficiently and lowering cutting zone temperatures.

Surface Finish & Post-Machining Options

After machining the components, it is always wise to apply some post-machining processes. Post-machining processes increase the durability of the parts by enhancing surface finish and corrosion resistance.

Electro-Polishing

Electro-Polishing is an electrochemical process which is used to remove surface imperfections.

Working Mechanism

- The Kovar part is dipped in an electrolytic bath of typical acid.

- A DC passes through the electrolyte and dissolves micro-cracks from the surface and making it smooth.

You can achieve a mirror-like surface finish, i.e. 0.1-0.3 Ra, through this operation.

Nickel and Gold Plating

This post-machining process adds some functional layers to the Kovar parts.

|

Parameter |

Nickel Plating |

Gold Plating |

|

Primary Purpose |

Wear resistance, solderability, and EMI shielding |

Oxidation resistance, high conductivity, RF performance |

|

Process |

Electroless or electroplated |

Electroplated (requires nickel underlayer) |

|

Typical Thickness |

5-25 µm |

0.5-3 µm (thin to minimise cost) |

|

Key Benefits |

-Improves hardness (500-600 HV); |

-Prevents tarnishing; |

|

Cost Comparison |

$0.50-$2.00 per square decimeter |

$5-$20 per square decimeter (gold price-dependent) |

|

Best Applications |

-Connector housings; |

-RF/microwave components; |

Vacuum Stress Relief

Machining often induces some stress within the structure of the material. Vacuum stress relief is a heat-treatment process which removes machining-induced stresses.

Working Mechanism

Kovar material is heated over 750oC, i.e. under recrystallisation temperature, in a high vacuum ≤10⁻⁵ mbar to prevent oxidation.

- It prevents distortion in thin-walled components.

How to Make Dimensional Control & Metrology

For mission-critical applications, it is non-negotiable to compromise the dimensional accuracy. These are the technologies through which you can verify dimensional accuracy:

For thin-wall tolerances

Use slow, light finishing passes to achieve dimensional accuracy of ±0.025 mm without deflection.

Non-contact metrology

You can use white light interferometry to inspect surface roughness <1 µm.

To check internal features, you can use CT scanning.

Helium Leak Testing

It can detect very small leaks, i.e. 1×10⁻⁹ cc/sec. It is an essential test for pressure-critical assemblies.

Industry Case of Kovar Machined Parts

This section covers industrial applications of Kovar machined parts. Let’s begin with its applications in the aerospace field.

Aerospace IMU Housings

Kovar machined parts are used in inertial measurement unit enclosers in aeroplanes and satellites. Kovar provides exceptional thermal stability over -65°C to +150°C temperatures. It also provides magnetic shielding and hermiticity.

Medical Feedthroughs

Due to the following reasons, we use Kovar machined parts in medical feed throughs:

- Biocompatibility

- MRI compatibility

- Sealing Reliability

5G RF Packages

Kovar machined parts are used in 5 G base stations and radar systems for high-frequency RF modules. Kovar is used for good CTE matches, stable signal integrity and good thermal management.

Global Sourcing Tips for Kovar Machining

There are many factors, such as cost, quality and lead times, which affect buying Kovar machined parts from any country. That is how you can navigate a good supplier:

1. ASTM F15 Certification

Ensure the composition and traceability of the Kovar material and make sure that the supplier follows ASTM F15 certification.

2. Local vs. China Outsourcing

According to the following comparison table, for high-volume, simple designs and budget saving, China is preferable. If you need prototypes or tight-tolerance parts, you should go for the local or US option.

|

Factor |

Local (US/EU) |

China |

|

Cost |

$120-$250/hour |

$30-$80/hour |

|

Lead Time |

2-4 weeks (prototypes) |

4-8 weeks (+ shipping) |

|

Quality Control |

On-site inspections easier |

Requires 3rd-party QC (e.g., SGS) |

|

IP Protection |

Strong legal enforcement |

Higher risk of design leaks |

|

Example: |

100x Kovar RF shields: $18,000 (US) |

Same order: $6,500 (China) + $2,000 shipping |

3. Shops with Vacuum Furnaces

Always prefer those suppliers who are equipped with vacuum furnaces. Because their machined parts will be free of oxidation.

How TUOFA CNC Machining Masters Kovar Alloy Manufacturing

For Kovar machining services, you can come to TUOFA precision machining. We offer precise machining to achieve tight tolerances. We are equipped with vacuum furnaces to provide the best stress-free and non-oxidised parts. You can come to us for the fast delivery times and the best machining properties.

Conclusion

Kovar is a vacuum-melted material and used in critical applications due to its lowest thermal expansion property, good temperature stability and hermetic sealing capability. But its work-hardening phenomenon and surface abrasiveness cause very specialised and careful machining.

FAQs of Kovar Machining

What material is equivalent to Kovar?

For the thermal expansion case, Fernico and alloy 42 are equivalent to Kovar.

Which cutting fluid works best for Kovar?

You can use synthetic coolants with high lubricity. It will reduce the temperature and hence the tool wear.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Honing Definition and Process Guide for Precision Surface Finishing

Honing Definition and Process Guide for Precision Surface Finishing