Liquid Cooling Parts in PC Cooling System: Process, Materials, Benefits

Nov 07,2025

Nov 07,2025

With the ushering of AI and the evolution of our computational needs, computing environments are becoming denser. Powerful computers require a large input of energy. This creates a big thermal load. Traditional air cooling does not provide an adequate solution for these systems. So, more and more tech firms are adopting liquid cooling. The manufacturing of the liquid cooling parts require a high precision. Let’s check out the common processes and materials in liquid cooling parts manufacturing.

What Are Liquid Cooling in PC Cooling System

Nowadays, as the computational demand is high, so is the thermal load on computers. In comparison to the traditional air cooling, liquid cooling parts, the computer system cooling parts, provide superior cooling performance. As a result, compact systems can be made with an ambient thermal environment.

What Is Liquid Cooling System

Liquid cooling systems is a heat management solution for computers. It is an automatic system with a feedback loop mechanism that maintains optimal temperatures. A coolant is circulated to cool down CPUs and GPUs to an optimum temperature range. Liquid cooling parts consist of water block, pump, radiator, fans, sensors and actuators.

How Does Liquid Cooling System Works

The main mechanism of a liquid cooling system is to circulate a liquid to drive off heat. The liquid is normally distilled water or some proprietary solution. The pump flows the coolant to water cooling block which absorbs heat from liquid cold plates attached with CPU/GPU. The coolant then moves to the radiator where it cools down for another circulation. Sensors and actuators form a feedback loop to maintain the temperature within an optimum range.

Why Liquid Cooling System Is Important

The development of AI models and a large number of LLM (Large Language Models) has exacerbated issues such as server overheating on the hardware side, making better liquid cooling systems a key focus. In order to improve the computational performance, Google, Microsoft, and NVIDIA, have adopted liquid cooling and immersion cooling technologies.

Liquid Cooling Vs Air Cooling

|

Feature |

Liquid Cooling |

Air Cooling |

|

Efficiency |

High heat transfer |

Moderate |

|

Noise |

Quiet |

Noisy |

|

Maintenance |

Occasional upkeep |

Low upkeep |

|

Cost |

Expensive |

Affordable |

|

Best For |

High-performance PCs & AI servers |

Everyday desktops |

Key Liquid Cooling Parts List in PC Cooling Systems

Liquid cooling parts work in synchronization to regulate temperatures. Some liquid cooling parts are made up high conductivity metals like Aluminum and Copper. They are precision machined in a CNC. Other parts are made up of polymers. Electronic sensors and actuators regulate the working of these liquid cooling parts.

What Is The Main Part in Liquid Cooling?

Water block and radiator provide the core heat path. Water cooling block absorbs heat from the CPU/GPU and radiator radiate the heat outside the system. Lets learn about the heatsink parts and auxiliary components of a liquid cooling system.

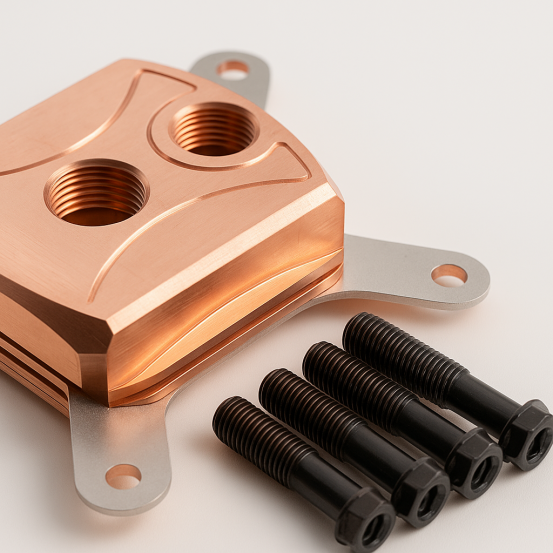

1.Water Blocks

Water cooling block parts list includes a base and a top cover. The base is usually made up of high conductivity metals like Aluminum or Copper. The top cover is made up of Aluminum. The base need precision machining to create a good contacting surface with the CPU/GPU.

- CPU Water Block: It is mounted over the CPU’s IHS for heat transfer

- GPU Water Block: Covers GPU die and VRM zones for cooling

Liquid Cold Plates vs Water Blocks

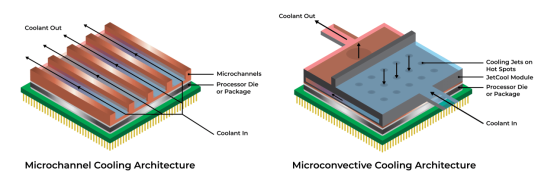

Liquid cold plates are flat and water cooling blocks have CNC milled fins. Liquid cold plates provide a uniform cooling. On the other hand, water cooling block have internal fins to dissipate heat rapidly.

The Role of Water Block in Liquid Cooling

Water cooling block plays a vital role in the liquid cooling system. It absorbs heat from the CPU/GPU and then transfers it to the circulating coolant.

2.Heat Rejection

Radiators

Radiator absorbs heat from the coolant and dissipates it to the outside. They are made up of high thermal conductivity metals. Radiators are often CNC machined to include design features that dissipate heat quickly.

Fans for Radiators

Fans force air onto the radiator surface for better convection currents.

The Role of the Radiator in Liquid Cooling

Radiator rejects heat away from the liquid cooling system. Without it the lowering temperature of the system is very difficult.

3.Flow Generation And Control

Pumps help to circulate the coolant throughout the system with the desired flow rate. Sensors and actuators control the flow rate automatically. Pumps often have CNC machined housings with impellers for a reliable flow control.

4.Interconnects and Sealing

Fittings, couplings, and seals prevent leakages of coolants. Robustness of the pipes and fittings is necessary to prevent any loss. It is recommended to use CNC turned brass or stainless-steel fittings with precise threading.

5.Tubing and Lines

Tubing and lines route the coolant through it.

6.Sensors And Monitoring

Sensors for flow detection and temperature detection are installed in a liquid cooling system. As flow or temperature fluctuates from the optimum range, circulation of coolant is activated accordingly.

7.Service And Accessories

Proper alignment and clamping is crucial for liquid cooling parts. For that purpose, CNC machined mounting brackets, backplates, and hardware are used. CNC machines give high precision for proper fitting.

8.Custom Machining Parts

Micro-channel bases, pump housings, manifold blocks, and mounting frames are some of the frequently ordered CNC liquid cooling parts.

CNC Precision Machining of Liquid Cooling Parts

Since liquid cooling systems are sensitive, a high level of precision is required in the manufacturing of liquid cooling parts. A good CAD is the first step to do that. If the CNC shop gets an accurate DFM, there is only a negligible chance that product will get faulty.

DFM for Water Blocks and Cold Plates

DFM for water cooling blocks and liquid cold plates need a careful consideration. The main objective should be to optimize flow channels, wall thickness, and seal integrity. Special features like micro-channels or pin fins should be simulation tested for heat transfer efficiency. The below table gives some DFM tips:

|

Aspect |

Purpose |

DFM Tip |

|

Thickness |

Structural and thermal stability |

Keep uniform to avoid distortion |

|

Channels |

Coolant flow and heat transfer |

Ensure cutter access and smooth flow |

|

Micro-Fins |

Increase surface area |

Match tool size to avoid undercuts |

|

Sealing Grooves |

Leak prevention |

Tight tolerance and smooth finish |

|

Mounting Holes |

Secure clamping |

Even spacing to prevent warping |

|

Alignment |

Proper sealing and fit |

Use dowel holes machined in one setup |

|

Material |

Thermal and corrosion performance |

Use Cu/Ni for high transfer, Al for light weight |

How to Machine Liquid Cooling Parts

3–5-Axis CNC Milling

3 axis CNC milling is mainly used for simpler shapes with a high throughput rate. In contrast to it, 5axis milling is used for complex micro-channel arrays and angled passages. In CNC milling, high spindle speeds and carbide tools are preferred to achieve smooth internal flow paths.

Wire EDM and Micro-Drilling

Wire EDM and micro drilling ultra precise cuts without burrs. They can machine out coolant entry and exit ports with a precision of 0.3mm. This high precision ensures good leakage proofing.

Tapping and Thread Milling

For liquid cooling parts, threads must be clean to maintain sealing integrity under pressure. Threads are made in liquid cooling parts for fitting of components.

How to Choose Post-Processing and Finishes

Electroless Nickel and Mirror Nickel

Nickel plating offers excellent corrosion resistance and aesthetic appeal. Electroless nickel plating can be done with aqueous solutions across complex channels.

Anodizing Options

Radiators and housings in liquid cooling parts are often made up of Aluminum. Type II clear anodizing provides a good corrosion resistance with a range of colors.

Sometimes radiators are black anodized to give better thermal radiation.

Challenges in Machining Water Cooling Blocks

- Maintaining tight tolerances on thin walls and channel depths.

- Chip evacuation in micro-channel machining.

- Distortion control during heat buildup.

- Surface finish consistency on sealing faces.

Common Materials Used in Liquid Cooling Parts

Liquid cooling parts are made up of number of components. Each component has its own function which demands suitable material properties. Some parts need high thermal conductivity while others need high corrosion resistance. Then comes the cost factor. An expert CNC manufacturing facility can guide you about choosing the right materials.

Determine Your Design Purposes

Different materials have their own properties which address to different functions in various design purposes. Come to TUOFA for expert quote to choose the proper materials.

Metals in Liquid Cooling Parts

Copper Series

C110 is an ideal material for water cooling block. It is 99.9% pure copper with a very high thermal conductivity. It is easy to braze and solder. C102 is also a very high purity grade which is oxygen free. It is also used in the manufacturing of water-cooling block and Liquid cold plates. Nickel plating on copper makes is very aesthetically pleasing and corrosion resistant.

Aluminum Series

Pump housings, manifolds, and mounting frames are commonly made up of 6061 grade. It offers excellent machinability and anodizing response. Grade 6063 aluminum is mainly used in radiators and enclosures.

Brass and Stainless Steel

Threaded fittings, couplings, and valves are often made up of brass or stainless steel. Brass offers a very good machineability. It thus has a very high level of precision. On the other hand, stainless steel is lower in cost, it is corrosion resistant and it has a very nice surface finish.

Polymers and Plastics

Acetal/POM

Pump bodies and reservoirs are often made up of acetal. It is tough and chemically stable.

Acrylic/PMMA

Water block covers are often made up of acrylic because it is transparent.

Why Copper Is Perfect for Liquid Cooling Parts

Copper offers a superior performance in liquid cooling applications. It has high thermal conductivity, high machinability, high strength and a high durability. Although its cost is a bit high but the performance advantage that it gives weight more than its cost. Commonly, you can find the copper cold plate (such as C110 copper), as known as the water block base, in many PC cooling system parts.

High Thermal Conductivity

The thermal conductivity of copper is 400 W/m·K which is almost twice the conductivity of Aluminum. Higher thermal conductivity means faster cooling and better performance. Copper heat sinks lower the temperature 5-10 O C more than Aluminum heat sinks.

Microchannel Machinability

As copper has an excellent machinability, micro channel water cooling blocks or liquid cold plates can be made with complex designs. As an example, thinner thin fins with narrow passages can be made. These denser channel designs offer high-power-density cooling.

Stable Contact Flatness

Liquid cooling parts made up of copper give a better precision. They have comparatively lower residual and thermal stresses. Dimensional stability offer a near perfect flatness.

Brazing And Soldering Compatibility

Copper is compatible with almost all brazing and soldering operations. Nickel plating can be performed on Copper parts to enhance durability and aesthetics.

Liquid Cooling Parts Manufacturers at TUOFA China

TOUFA is a reputable name in CNC manufacturing industry in China. We have successful record of OEM manufacturing. In addition to several other industries, we have specialized in liquid cooling parts manufacturing. Feel free to send us an inquiry. Our dedicated team will provide you the best solutions.

What We Make

CPU and GPU Water Blocks

We provide CNC manufacturing solutions for OEM water blocks. We can handle any level of complexity in design for optimal heat transfer. Our precision machining provide leak proof sealings connections.

Liquid Cold Plates

We utilize CNC milling, wire EDM, and vacuum brazing for microchannel and pin-fin designs. Our QA/QC team ensures flatness control for better heat transfer.

One-Stop Custom Solution for Liquid Cooling Parts

TOUFA provides a one-stop custom solution for liquid cooling parts. We can easily scale from prototype design to mass production. Our CNC machining facility can manufacture water cooling blocks, liquid cold plates, radiators, manifolds, fittings, and housings with perfection. Our finishing facility provides surface treatment like anodization and nickel plating. Our client gets the liquid cooling parts as per the DFM.

Capabilities

5-Axis Milling and EDM Services

We have advance 5-Axis Milling capabilities. Our EDM services enables ultra-fine channel cutting and micro-hole features.

EN Nickel, Anodizing, and More

We offer a complete range of finishing services like electroless nickel plating, anodization (Type II and Type III), black anodization and polishing.

How to Get Quote from TUOFA?

Please feel to send us your inquiry at email or fill in this table to send us technical drawings, our dedicated team will get back to you→→→

The Role of Liquid Cooling in the Future

With the support of AI, big data algorithms have greatly improved their computing power, but they have also brought new challenges to hardware technology support. The more the computation power, the higher the energy input and the high the thermal load. Hence, more efficient cooling systems are required in the future.

Rising CPU, GPU TDP and AI Workloads

As AI-driven computing continues to grow TDP of modern CPUs and GPUs is increasing. High density computing environments cannot depend on traditional air cooling. Liquid cooling provides an efficient solution.

Conclusion

In comparison to the tradition air cooling approach, liquid cooling is faster, quieter and more efficient. As the liquid cooling system is quite sensitive, it requires dimensional precision for proper fitting. CNC machining facilities like TOUFA provide a one stop solution for OEM manufacturing of liquid cooling parts.

FAQs about Liquid Cooling Parts

Can I use pure copper to make waterblocks?

Grade C110 is almost 99.9% pure copper. It is commonly used in high performance waterblocks.

Is nickel plating safe, and why does it sometimes flake?

Nickel plating is safe for liquid cooling parts. It flakes only when the surface preparation is inadequate.

What are the benefits of liquid-cooled engines?

Liquid cooling is more reliable, faster and quieter.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Understanding Pitch Diameter: Design, Manufacturing & Gauging

Understanding Pitch Diameter: Design, Manufacturing & Gauging