How to Demagnetize Metal? Something You Must Know

Oct 16,2025

Oct 16,2025

We all have experienced the sticking of screws with our screwdrivers. Whenever we wanted to tighten a screw it sticks with the screwdriver and doesn't come off easily. This thing always drives us crazy. This may sound harmless but an invisible force remains inside the metal and causes various problems at large scale. This phenomenon is called magnetization and there are many ways to get rid of it. In this article below, we will see how to get rid of magnetization or you can say demagnetize the metal.

What Is Demagnetization?

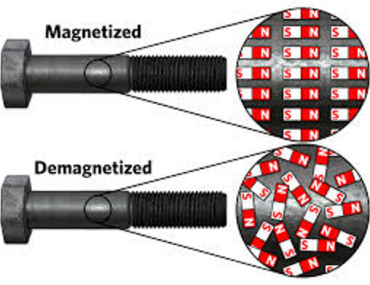

Demagnetization is basically when you remove the attractiveness of a metal and it doesn't stick to other metal parts. If a metal is magnetic, it creates a field lines around it. In easy words, consider an example like you are in a class and all students are facing toward the white board, it states uniform field lines means magnetic. On the other hand, students are sitting random facing different directions means no magnetism. The former is the one we want to do.

Fig 1: Magnetization vs Demagnetization

How Parts Become Magnetized in Machining

Parts don't become magnetized due to magic. There will always be a phenomenon or reason behind it. Let us see some common reasons:

|

Machining like cutting or grinding |

Friction happens when you cut a metal part. This friction kind of aligns the magnetic domains in metal so that is why part becomes magnetic |

|

Magnetic particle testing |

This is an NDT technique. In this a magnet is placed on a metal to detect cracks. Sometimes the magnet makes the part magnetic by sipping into the metal. |

|

welding |

Welding technique can be another reason. In this high current pass the magnetism into the part |

Table 1- Magnetization due to different mechanisms

Problems Caused by Residual Magnetism

A lot of problems are faced due to residual magnetism like:

- Chips start sticking to machined parts and destroying the beautiful finishes of metal part.

- Wrong reading will be given by gauges because magnetic lines interfere with the tool.

- Arc blow is seen during welding like the arc gets distorted due to residual magnetism.

Fig 2- Different nails and chips attached to part due to grinding

Typical Acceptance Limits for Residual Field

Every industry has different acceptance limit for the residual magnetic fields. The table below will give some general acceptance limits.

|

Application |

Maximum Residual field |

|

General machining |

< 2 Gauss |

|

Precision measurement |

< 0.5 Gauss |

|

Welding |

< 3 Gauss |

|

NDT Inspection |

< 2-3 Gauss |

Table 2- Applications and maximum acceptance residual field

How Demagnetization Works?

So the demagnetization works is when you disturb the aligned magnetic domains in the metal part. Means you change the uniform direction of field lines which causes' demagnetization.

Principle of Demagnetization

As discussed above there are some domains when aligned acts like small magnets. So by some external method we dis-align those domains which remove the magnetic power of metal. This is the principle of magnetization.

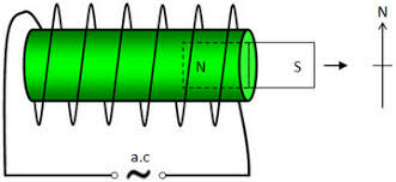

Alternating Field Decay

The most common method which is used by many people is the Alternating field decay or AC decay. As we all know that AC has many cycles or directions per second. You can recall the sin wave going positive and negative. This changing directions also changes the magnetic domains inside the metal and slowly reducing the current un-aligns all the domains which causes demagnetization.

Heat Demagnetization Basics

Another method by which magnetization is removed is by heating the metal part. There is a temperature called the Curie temperature which is different for each metal. So when temperature reaches that point, the metal loses all the magnetization power. But it also impact other factors like strength etc. of the metal.

For better understanding:

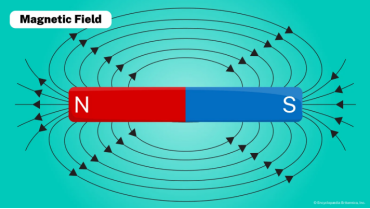

Fig 3- Magnetic field of a Magnet

1- AC Degaussing Method (Alternating Current)

This is the same as the alternating field decay mentioned above. In short, AC current changes the uniformity of the magnetic domains rotating them back and forth and slowly reducing the current side by side. By this the domains stay in some random directions as the current ends.

Select the Right Demagnetizer

Every metal part has different size, shape and properties. So finding the right demagnetizer is very crucial. Let's look at some common demagnetizers.

|

Tunnel coil |

This is a circular type and parts go through it. For example big shafts, rods etc. |

|

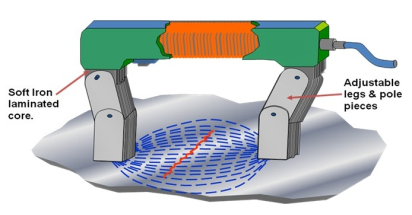

Yoke type |

It is usually for flat parts or metal sheets. |

|

Handheld demagnetizer |

It is used for small components like nuts and bolts. It is portable and used by our own hands. |

Table 3- Types of demagnetizers

Orient the Part for Full Coverage

When demagnetizing, make sure you rotate the part slowly and also pass through the tunnel coil multiple times to ensure complete and smooth magnetization.

Ramp the Field Down to Zero

Make sure when passing the metal part through the demagnetizer, start reducing the current side by side so that when current becomes very low, the magnetic domains are in different directions.

Verify Residual Magnetism

After demagnetization, you can never assume the part is fully demagnetized. As a safety measure always use the gauss meter and check the reading from multiple sides. If the gauss meter gives reading, again repeat the process of demagnetization.

Fig 4- A simple AC Degaussing method schematics

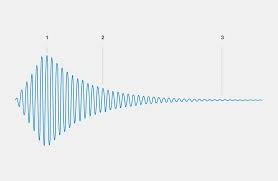

2- Pulse Demagnetization (Capacitive Discharge)

There are some stubborn parts on which AC demagnetization doesn't work. So for this, pulse magnetization is used. It is usually a powerful energy burst that destabilizes the magnet domains in the metallic part.

Choose the Right Coil

Choosing the right coil is necessary as it must fit your part. Or the part must go through easily. It is crucial due to its right penetration.

Set Pulse Energy and Decay

You should start with a low pulse energy and increase if needed. A controlled slower decay works more good than high pulse energy as it can demagnetize more good than the high one.

Control Heating and Safety

A high pulse can heat the part very quickly so it is dangerous. It can also change the property of that part due to heating so keep some of the consequences and safety factor in mind before proceeding.

Verify Residual Magnetism

Same as above in this case, after removing magnetic power from metal part. Use gauss meter to ensure that all the magnetism is removed before proceeding.

Fig 5- A pulse demagnetization Graph

3- Demagnetizing Without Specialized Equipment

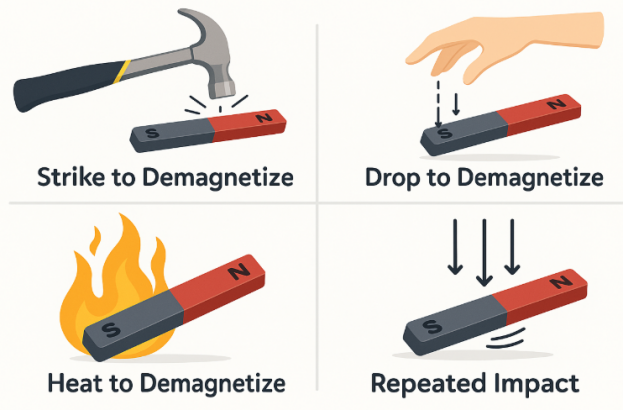

In case you do not have some specialized equipment's, it is still possible to demagnetize parts. Let's discuss some methods below:

Make a Simple AC Loop

You can make a simple AC loop to demagnetize a metal. Wrap some wire around the part. Let's take the example of shaft. Wrap wire around it, connect it to AC and slowly start pulling the shaft through the loop creating a decaying AC field. But safety is very priority in this as current is passing though the wire loop and shaft.

Use Heat with Caution

Use a blow torch to slowly heat the metal until it is dull hot. It is usually in case of steel. It can demagnetize the part but will destroy it heat treatment properties.

Tap or Vibrate the Part

One of the simple methods is by slowly hitting the metal part with a hammer or other external object. It will create vibrations destabilizing the magnetic domains in the part.

Try a Battery-and-Coil Setup

The easiest method is this one. Same as AC wire loop. Use a 9V battery instead of AC current and make a coil setup. Slowly move the part through it decaying the magnetization of metal part.

Fig 6- Simple demagnetization techniques without specialized tools

Demagnetizing Before Welding and NDT

One of the most crucial steps in welding is the demagnetization of the parts which are to be welded. Same is the case with the NDT methods. Let' discuss why it matters.

Why Do You Need Demagnetize Before Welding?

As we know that if a metal is magnetized, it can alter the current direction. So when during welding, arc is produced, magnetized metal alters the direction of the welding arc causing incomplete fusion and porosity in the metal.

Control Arc Blow at the Weld

Controlling arc blow is very important in the welding. That is why the above mentioned techniques are used to demagnetize the metal part first. After the metal to be welded is completely magnetized, it is gone to the welding procedure.

Meet NDT Residual Field Limits

NDT techniques like magnetic particle inspection require clean state or demagnetized metal. It should be less than 3 gauss as it can hide real defects or create fake ones.

Fig 7- Magnetic Particle Inspection testing

Optimize Grounding and Fixtures

By grounding the metal part which is to be welded can also help in the welding procedure. The ground part will make the metal less magnetized and welding can be done. But always try to follow the procedure of demagnetizing metal first.

How to Demagnetize Metal?

Let's look at some real life scenarios which we have to face in our daily life. Like demagnetizing metal pipes for welding, piece of steel and screws:

How to Demagnetize Metal Pipe for Welding

- Make a big coil enough to pass the metal pipe easily through it.

- Pass the metal pipe back and forth many times

- Also rotate the pipe

- Also reduce the coil power side by side for best result.

How to Demagnetize a Piece of Steel

- Let's consider a small block of steel

- For this, yoke type magnetizer is best.

- Slide the yoke type magnetizer on the surface of the steel piece many times

- Check with the gauss meter at the end to confirm demagnetization.

How to Demagnetize a Bunch of Screws and Other Fasteners?

- For screws or bolts which are usually small

- Collect them in a nonmagnetic tray.

- Pass the handheld magnetizer from the top.

- Shake or stir the tray for better coverage.

Demagnetizing Metals: What to Expect by Material

Every material behave differently due to different properties. When choosing a material, we have to think really wisely that application requires which material. Always know the surrounding in which material will work as materials get magnetized easily due to the above mentioned methods like grinding or polishing.

Magnetism of Ferromagnetic Metals

Ferromagnetic metals are the only materials that can be permanently magnetized. These include iron, nickel, cobalt etc. these are the hardest to demagnetize fully.

Carbon/Alloy Steel

These are very common magnetic materials. They have very strong field but they are also easy to demagnetize also using the AC or pulse method.

Stainless Steel: Austenitic vs Ferritic

This is where surprise occurs. Austenite and ferrite are both different phases of steel. But the main point is the austenite phases like 304/316 are non-magnetic. But when they are cold worked they become slightly magnetic. Whereas ferritic steel is already magnetic and they are difficult to demagnetize.

Tool Steel, PM Alloys

Tool steel or powdered metallic alloys are very hard. They are also highly magnetic and it is really difficult to demagnetize them. Pulse demagnetization can be used to demagnetize them.

How to Measure and Prove Residual Magnetism

Gauss meter is the device which can be used to measure and prove residual magnetism. It is mostly used by all the industries and mostly used by Quality control engineers as a protocol.

Fig 8- A digital Gauss meter

Conclusion

To conclude, demagnetization is one of the important aspect when metallic parts are used in the industries. As magnetic materials can create a lot of problems during welding or NDT testing so removing the magnetism is very important. Methods like AC or pulse demagnetization are used. Gauss meter is used to check the magnetization of material. It is done for the safety and reliance of different applications.

Why do workpieces become magnetized?

Workpieces become magnetized due to many machining processes. It includes grinding polishing etc. They become magnetized when due to machining the magnetic domains inside the material align themselves showing the properties of magnetism.

What temperature will demagnetize metal?

There is specific temperature called Curie temperature. For steels it is around 770C. Every metal has its own curie temperature.

Why stainless steel become magnetize after cold-work?

Austenitic stainless steels like 304 or 316 are nonmagnetic but when they are slightly bended or cold worked. The surface of the metal becomes slightly magnetized in which magnetic domains become aligned.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Liquid Cooling Parts in PC Cooling System: Process, Materials, Benefits

Liquid Cooling Parts in PC Cooling System: Process, Materials, Benefits