Subtractive Manufacturing: Processes, Benefits & When to Choose It

Jun 03,2025

Jun 03,2025

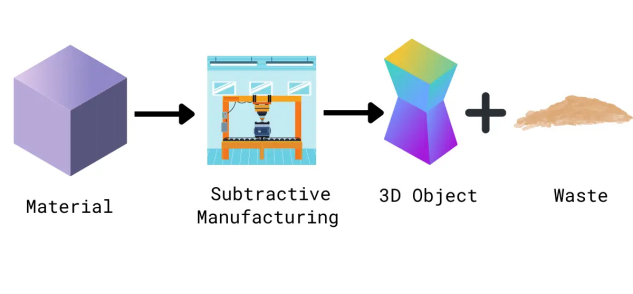

You will have an idea of what the word "subtract" means. It means to minus or to remove something. In subtractive manufacturing, material is removed from a solid block using various tools and technologies to achieve the desired shape. This article aims to illustrate the importance of subtractive manufacturing in our lives, highlighting its significance over additive manufacturing. You will study subtractive manufacturing technologies such as CNC, their benefits and when to choose. So, let's start by briefly understanding what subtractive manufacturing is.

What Is Subtractive Manufacturing?

In subtractive manufacturing, material is removed from a solid block to create the desired shaped products. You use different tools and machines to cut the raw material into real-world applicable products. It's been the backbone of automotive, aerospace and many other fields.

Definition and Core Principle

The core principle of subtractive manufacturing is to cut or remove material from a solid block using drills, lathes or lasers, etc.

From Manual Machining to CNC Evolution

Getting the most accurate dimensions of the workpiece has always been top priority. In this regard, the Industrial Revolution came. It became more important to achieve tight tolerance parts for the aerospace and automotive industries. Through manual machining, it was impossible or very time-consuming. To tackle these issues, the CNC (Computer Numerical Control) machine was introduced in the world of manufacturing as the most advanced manufacturing machine.

Role in Today's Digital Workflow (CAD → CAM → CNC)

You can't work on your workpieces directly on CNC machines. First, you need to design the part in CAD software, then convert it into toolpaths using CAM software. Then, you will be able to use CNC machines.

Common Types of Subtractive Manufacturing Processes

You are going to study some common subtractive manufacturing processes in this section.

CNC Milling (3-Axis to 5-Axis)

If the design of your parts is simple, then choose a 3-axis CNC machine. And for difficult designs such as impellers, use a 5-axis CNC machine because it adds rotational A/B axes as well.

|

Type |

Speed |

Accuracy (±mm) |

Cost ($/hr) |

|

3-Axis |

High |

0.05 |

80 |

|

5-Axis |

Medium |

0.02 |

150 |

CNC Turning & Swiss-Type Lathe

In CNC turning, the cylindrical workpiece rotates, and tools remove the materials. Best for cylindrical components, i.e. shafts.

You will use Swiss-type lathe when the components are tiny, e.g. watches screws.

Efficiency is dependent on the component size. In case of micro-parts, Swiss lathes are 3X faster than CNC turning.

|

Type |

Speed |

Accuracy (±mm) |

Cost ($/hr) |

|

CNC Turning |

High |

0.01 |

70 |

|

Swiss Lathe |

Very High |

0.005 |

200 |

Grinding, Honing & Lapping

Grinding

If you use an abrasive wheel to remove the material for sizing and shaping, then it is called grinding. Sometimes, it is used to achieve a good surface finish.

Honing

Abrasive stones are used to scrub the inner side of a hole or bore. You can use this process to improve dimensional accuracy and surface finish.

Lapping

Take a lap and a workpiece, add abrasive slurry between the surfaces and then rub. You will get a mirror-like surface finish.

|

Process |

Speed |

Accuracy (±mm) |

Cost ($/hr) |

|

Grinding |

Low |

0.002 |

100 |

|

Honing |

Very Low |

0.005 |

120 |

Honing provides the smoothest surface finish.

Electrical Discharge Machining

If an electrified wire cuts the material, it is called EDM Wire, and if you use an electrode to shape the cavities, it is called EDM Sink.

|

Type |

Speed |

Accuracy (±mm) |

Cost ($/hr) |

|

Wire EDM |

Low |

0.01 |

200 |

|

Sink EDM |

Very Low |

0.02 |

180 |

Waterjet & Fibre-Laser Cutting

Fibre-Laser Cutting

A focused laser beam melts, burns or vaporises the target material. You can use it for intricate shapes and tight tolerances.

Waterjet Cutting

If you use a highly pressurised stream of water, sometimes mixed with abrasive particles to cut through material, it is called waterjet cutting.

Quick Comparison Table

The following comparison table shows differences in the subtractive manufacturing methods.

|

Process |

Best For |

Speed |

Accuracy (±mm) |

Cost ($/hr) |

|

5-Axis Milling |

Complex 3D parts |

Medium |

0.02 |

150 |

|

Swiss Lathe |

Micro-components |

Very High |

0.005 |

200 |

|

Wire EDM |

Hardened metals |

Low |

0.01 |

200 |

|

Fiber Laser |

Thin metals |

High |

0.05 |

110 |

Subtractive Manufacturing Demo

Supported Materials of Subtractive Manufacturing

Subtractive manufacturing, like using CNC machines, allows you to get a variety of materials to convert them into real-life applicable parts. Unlike additive manufacturing, which struggles with material thermal stability and strength.

Metal Materials Types

This section presents some common materials used to make applicable parts through subtractive manufacturing. CNC machines and other subtractive manufacturing methods can work on many materials such as metals, plastics and composites. These are some common metals which are widely used in subtractive manufacturing:

Subtractive Manufacturing Aluminium

The most common aluminium alloys are 7075-T6, 7075 and 2024. You can make aerospace parts, such as wing ribs, and automotive parts, such as engine blocks, using subtractive manufacturing.

Subtractive Manufacturing Titanium

Grade 2(CP), Grade 5(Ti-6Al-4V), and Grade 23 (medical) are the widely used Ti grades in subtractive manufacturing. You can use them for landing gears, implants and many other things.

Subtractive Manufacturing Inconel

Inconel is a nickel alloy. Its common grades used in subtractive manufacturing are 718, 625 and 738. Inconel has excellent mechanical properties, and that is why it is used even in nuclear reactors. It is used to make turbine disks and downhole tools for aerospace and oil & gas industries, respectively.

Subtractive Manufacturing Steel

The most commonly used material in subtractive manufacturing. from mild steel to alloy steel, it is used in different applications, such as mild steel is used for frames, stainless steel for food equipment and tool steels for mould and cutting tools, etc.

Non-Metal Materials

As we mentioned earlier, you can have a wider variety of materials when you use subtractive manufacturing methods such as CNC machines. These are the non-metal materials used for subtractive manufacturing.

Engineering Plastics

Engineering plastics are specially designed materials for critical applications. Polyoxymethylene (POM) is an example of engineering plastics. Its applications are found in gears, bearings and medical devices. Other engineering plastics include Nylon and PEEK, etc.

Carbon-Fibre Composites

One of the most difficult materials to machine, but subtractive manufacturing or CNC machines do this job quite comfortably. It is used in aerospace structures, automotive components, and the sports industry.

TOP3 Hard-to-Machine Alloys

In this section, you are going to study about top 3 materials which are considered "hard-to-machine" materials.

- Inconel 718 CNC

It is difficult to machine because it work-hardens instantly. But CNC machines do this job easily. It is jet engine components and high-stress nuclear applications.

- Ti-6Al-4V CNC

Its machining is difficult because of poor thermal conductivity, which causes heat concentration. It is used in aircraft fittings and medical implants.

- Hardened Tool Steel (≥ 55 HRC)

It is a very hard material because of abrasive carbide wears carbide tools rapidly. It is used in injection moulds and cutting dies.

Tolerances, Surface Finish & Dimensional Accuracy

The main reason why we use subtractive manufacturing is that it offers superior tolerance, surface finish and dimensional accuracy as compared to conventional manufacturing methods. These properties increase a part's life and application success rate. Further data is discussed here in this section:

Typical Tolerance Bands by Process

Subtractive manufacturing consists of many processes, such as CNC machining, grinding, turning, etc. We will discuss the achieved tolerance through each process:

|

Process |

Typical Tolerance (±mm) |

Best For |

|

CNC Milling (3-axis) |

0.025 |

Complex 3D parts, moulds |

|

CNC Turning |

0.013 |

Cylindrical parts, shafts |

|

Grinding |

0.002 |

Ultra-precise surfaces, bearings |

|

Wire EDM |

0.005 |

Hardened metals, intricate contours |

|

Honing |

0.005 |

Cylinder bores, hydraulic components |

These values represent the standard capability of each process to achieve that tolerance.

Surface Roughness Metrics (Ra, Rz)

Surface roughness is an important property for any application. The rough surface of the parts leads to fatigue failures. It affects adhesion in coatings.

|

Process |

Typical Ra (µm) |

Best Technique to Improve |

|

CNC Milling |

0.8–3.2 |

Reduce feed rate by 30% + polished tools |

|

Grinding |

0.1–0.4 |

Use finer grit wheels (220+ grit) |

|

Honing |

0.05–0.2 |

Increase stroke speed + diamond stones |

|

EDM |

1.6–6.3 |

Multiple skim cuts + fine electrodes |

Grinding provides the highest level of smoothness, i.e. mirror-like surface finish.

Quality Control: In-Process Probing & CMM

In-process probing and CMM (Coordinate Measuring Machines) are the two advanced features of subtractive machining. They ensure accuracy and provide quality control in machining.

In-process probing provides real-time verification during machining, which reduces scrap rate by 40%.

CMM is a post-process inspection gold standard. It has micro-level resolution and provides 3D surface mapping for complex geometries.

Major Waste Streams and How to Reduce Them

Subtractive manufacturing methods come with one major disadvantage, but it is manageable. It is the waste streams, but now the advancements have made it possible to reduce or recycle those waste streams.

Metal Chip Recovery & Scrap Value

Now, metal chips produced during machining are important because you can sell the waste and make revenue. For example, aluminium chips are sold in $1.50–$2.50/kg due to the high demand for recycling.

Coolant Use, Filtration & Disposal

The coolants are widely wasted before their dates, as these fluids can easily be useful for 3 months. You can use filtration systems, which further enhance crude oil's life. Dirty coolants can affect tools, so they must be disposed of quickly.

Energy Consumption & Carbon Footprint

To slash energy bills, you must know where the electricity is being consumed, like a spindle that takes 60% of the total energy. To reduce energy consumption and carbon footprint, use high-efficiency tools, and do big machining operations at night because of cheaper electricity rates. You can use solar panels as well.

Advantages & Limitations of Subtractive Manufacturing

This section provides insights into the advantages and disadvantages of whether you use subtractive manufacturing, i.e. CNC machines.

1. Setup & Fixturing

- Advantages

- A good setup and fixture can be repeatedly used

- High precision alignment

- Modular fixtures provide fast changeovers

- Limitations

- High Initial costs

- If your parts are large or of odd shapes, you need custom, expensive fixtures

2. Bulk Material Removal

- Advantages

- 10X material removal than additive manufacturing

- Nicely machine hard materials as well

- 20-30% less waste production

- Limitations

High-power use

3. Finish Machining

- Advantages

- Superior surface finish, i.e. Ra 0.4 µm

- You can achieve ±01 mm

- Often, post-processing is not required

- Limitations

Tool wear can occur and slower machining rate for finishing

4. Post-Machining

- Advantages

No sintering required after CNC machining

CNC-machined parts are easy to inspect

- Limitations

- For sharp edges, deburring may be required

- Higher stress risks

When to Choose Subtractive Manufacturing

- Tight Tolerances Below ±025 mm

- Metals or Filled Plastics That 3D Printing Can't Match

- Cosmetic Surfaces Ra ≤ 4 µm Out of the Machine

- Low-to-Medium Production Volumes Needing Repeatability

- Full-Density Parts for High Structural Loads

- Simple Tool-Reach Geometry Without Deep Internal Cavities

Industrial Precision Subtractive Manufacturing: TUOFA Precision CNC Machining

TUOFA is a Chinese company, well-experienced in precision CNC machining. We offer you CNC machining at the best rates and fast delivery. The following are the reasons why you should come to TUOFA for machining your parts.

±0.02mm Precision Machining

±0.02mm means the very tight tolerance used in automotive, aerospace and medical industries. But TUOFA specialises in achieving ultra-high tolerances.

Machining on Demand

- Fast Delivery rates for prototypes and other parts

- You can come to us for low production as well

Various Material Selection

We can machine a variety of materials using our precision CNC machining. We can machine metals (Al, Ti, steel alloys, Inconel), plastics and composites.

lSO9001 Certificate

We strictly follow the ISO 9001 standard for quality assurance. We follow IATF 16949 for automotive components as well.

Conclusion

We conclude that subtractive manufacturing is the backbone of innovation. CNC machines are becoming smarter and faster. AI will soon be able to optimise toolpaths automatically. This feature will be helpful for 24/7 production, which means even faster production. Additive manufacturing is an emerging technology, but CNC machines still play a big role in high-strength metal parts.

FAQs on Subtractive Manufacturing

What process achieves the tightest tolerances?

Grinding can achieve ultra-tight tolerance, i.e. ±0.002mm.

Can subtractive methods machine composites?

Yes, CNC machines can easily machine composite materials due to advanced features.

Why choose CNC over 3D printing for metal parts?

Because you can achieve superior strength and surface finish using CNC machines over 3D printing.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Zinc Alloy Machining-Grades, CNC Techniques & Practices

Zinc Alloy Machining-Grades, CNC Techniques & Practices