What is 41Cr4 Steel? Everything You Should Know

Jan 13,2026

Jan 13,2026

41Cr4 steel is a strong alloy that beats many steels like C45 in hardening. It also possesses remarkable mechanical properties, making it suitable for machineries manufacturing. Other technical and mechanical aspects of 41Cr4 alloy steels are discussed in this article along with their pros and cons and applications.

What is 41Cr4 Material?

41Cr4(EN 1.7035/DIN 1.7035) is basically a medium carbon chromium alloy steel. After heat treatment, it offers a great balance of strength, toughness, and wear resistance. 41Cr4 is a structural steel alloy and mostly used in the automobile and general engineering industries.

Chemical Compositions of 41Cr4

The main alloying agent in the chemical composition of 41Cr4 which primarily improves its properties. According to EN 10083-3:2006, other elements in the chemical composition include:

|

Chemical Element |

Percentage (%) |

|---|---|

|

Chromium (Cr) |

0.90 - 1.20% |

|

Carbon (C) |

0.38 - 0.45% |

|

Manganese (Mn) |

0.60 - 0.90% |

|

Silicon (Si) |

0.10 - 0.40% |

|

Phosphorus (P) |

Max 0.025% |

|

Sulfur (S) |

Max 0.035% |

The chromium content is an important addition. It improves the hardenability of 41Cr4. Hardenability is the ability to achieve high hardness deeper into the alloy. Furthermore, the steel has noteworthy strength, wear resistance and fine grain structure due to chromium. Another important element is manganese that contributes promisingly to wear resistance.

Is 41Cr4 Steel Important?

41Cr4 steel is a critical engineering material because it is widely used in manufacturing and machining industries. It specifically shows versatile properties when subjected to heat treatments like quenching and tempering. Its importance comes from its high strength and wear resistance, versatility in heat treatment, and good machinability for CNC machining. And most importantly this steel material is cost-effective for many high-stress, medium-duty applications.

Mechanical Properties of 41Cr4

Mechanical properties of 41Cr4 like strength, toughness, and wear resistance, make it desirable steel for different industrial applications. These properties can be further improved after heat treatment. In fact, the mechanical properties of 41Cr4 heat-treatable steel must be evaluated based on its specific heat treatment state. Especially the quenching and tempering (Q&T) condition are crucial for achieving and optimal balance of strength and toughness.

41Cr4 in Annealed Condition

41Cr4 low alloy steel in the annealed condition shows its lowest strength and hardness but highest ductility and best machinability. According to the material datasheet (TDS) from some steel suppliers, this condition has maximum softness and is highly suitable for primary machining processes like rough CNC machining, mechanical cutting, or pre-forming operations before final hardening treatments such as cold heading.

|

Mechanical properties in annealed conditions |

Values |

|---|---|

|

Tensile Strength |

570Mpa |

|

Yield Strength |

295Mpa |

|

Elongation |

28.6% |

|

Reduction of Area |

57% |

|

Impact Charpy-V |

41 |

|

Hardness |

157HBW(Brinell) |

41Cr4 in Normalized Condition

41Cr4 in normalized condition has a more uniform and refined grain structure compared to the as-rolled state. This resulted in better improved mechanical properties over the annealed condition and is characterized by a balance of strength, toughness and hardness of 41Cr4 chromium steel. This state is often specified when mechanical structural components need uniform mechanical properties throughout the material cross-section.

|

Mechanical properties in normalized conditions |

Values |

|---|---|

|

Tensile Strength |

795Mpa |

|

Yield Strength |

470MPa |

|

Elongation |

22.7% |

|

Reduction of Area |

59% |

|

Impact Charpy-V |

38 |

|

Hardness |

229HBW |

41Cr4 in Quenched and Tempered Condition

The quenched and tempered condition is the most important heat treatment for 41Cr4 steel. This process resulted in 41Cr4 properties with high-strength core and is the reference state for most engineering designs of load-bearing parts. A fine tempered martensite structure is achieved which has excellent balance of high strength with good toughness and wear resistance. The hardness of 41Cr4 material is ideal for parts like gears, axles, and crankshafts. You can check the details from the Technical Data Sheet below.

|

41Cr4 properties in quenched and tempered conditions |

Values |

|---|---|

|

Tensile Strength |

≥1000 |

|

Yield Strength |

≥800 |

|

Elongation |

≥9 |

|

Reduction of Area |

≥45 |

|

Impact Charpy-V |

≥60 |

|

Hardness |

240 to 359 HBW |

Reading the following comparison table for a clearer understanding of 41Cr4 steel's properties in all heat-treatment conditions.

|

41Cr4 properties |

Annealed Condition |

Normalized Condition |

Quenched and Tempered Condition |

|---|---|---|---|

|

Hardness |

157HBW |

~229 HBW |

240-359 HB |

|

Tensile Strength |

~570 MPa |

~795 MPa |

1000 MPa |

|

Yield Strength |

295Mpa |

~4705Mpa |

800 MPa (min) |

|

Ductility(elongation) |

28.6% |

22.7% |

9% (min) |

|

Machinability |

Excellent |

Normal |

Good (before hardening) |

|

Toughness |

Normal |

Good |

High |

|

Wear Resistance |

Normal |

Good |

Excellent |

Advantages of 41Cr4 Steel

After heat treatment (quenching & tempering) of 41Cr4 material, the improved mechanical properties make it a desirable material with many advantages such as:

High Strength

41Cr4 chromium steel can achieve tensile strengths of 850-1000 MPa with good impact resistance after heat treatment. Furthermore, high toughness, hardness and wear resistance prevent fracture under high stress or shock loads.

Excellent Heat Treatment Capability

41Cr4 can be induction hardened or flame hardened for localized wear resistance. It also has excellent properties after oil quenching and tempering. It can also offer customized properties for specific needs, like surface-hardened gear or through-hardened shafts.

Good Machinability

After quenching and tempering, 41Cr4 is easier to cut and shape than some higher alloy steels with better fabrication. It is used where precise machining is needed like gears or bevel gears.

Cost-Effective

41Cr4 along with balanced mechanical properties for demanding applications is highly economical material also than many complex alloy steels like 42CrMo4.

41Cr4 Equivalent Materials

There are many materials that are considered equivalent of grade 41Cr4 due to having similar chemical compositions and engineering applications.

AISI 5140 Steel

AISI5140 steel is a direct equivalent to 41Cr4 in terms of carbon (0.38-0.45%) and chromium content. However, the main difference lies in maximum allowed Phosphorus. AISI 5140 has max 0.035% P which creates a good balance of strength and ductility, while 41Cr4 is slightly stricter at a maximum of 0.025% P.

SCR440 Steel

41Cr4 material and SCR440 Japanese standard are closely matched in chemical composition ranges. But similar to 5140, the difference is the maximum limit of Phosphorus and sulfur (0.03% both in SCR440). These are minor variations in maximum impurity levels which increases its toughness and impact resistance.

530m40 Steel

530m40 UK grade is explicitly listed as a direct equivalent to 41Cr4. This British standard has high tensile strength and good wear resistance. The chemical compositions and mechanical properties of 41Cr4 are aligned with European and international ISO standards for the same applications.

|

Standard |

Grade Designation |

|---|---|

|

EU/EN |

41Cr4 (1.7035) |

|

USA |

AISI/SAE 5140 |

|

Japan |

JIS SCr440 |

|

UK |

BS 530M40 |

|

China |

GB 40Cr |

Comparison between 41Cr4 and Other Steels

There are many materials that are compared to 41Cr4 to determine suitability for different stress, wear, and heat treatment requirements in various applications.

41Cr4 vs 42CrMo4

42CrMo4 has molybdenum addition in its composition which significantly improved the mechanical properties over 41Cr4. It has higher hardness, strength, fatigue life and cost than 41Cr4. 41Cr4 is used in parts with lower strength requirements than 42CrMo4.

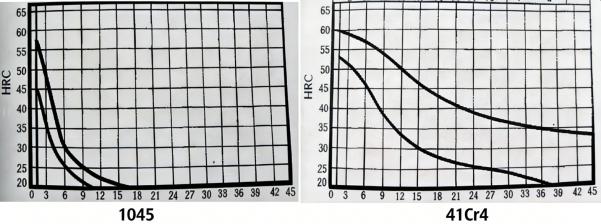

41Cr4 vs AISI 1045

41Cr4 is a chromium alloy steel, while AISI 1045 is a plain carbon steel. 41Cr4 has high hardenability, wear resistance than 1045. But 1045 has better machinability and lower cost.

41Cr4 vs 25CrMo4

25CrMo4 has lower carbon content than 41Cr4 and presence of molybdenum inclusions. 25CrMo4 has better ductility, weldability and creep resistance at higher temperature than 41Cr4. And 41Cr4 has higher strength and surface hardness after heat treatment.

41Cr4 vs 41CrS4

41Cr4 and 41CrS4 are chromium alloy grades of Germany, which belong to controllable hardenability steel. But are they the same? In fact, the key difference between 41Cr4 and 41CrS4 is the content of S chemical composition. 41CrS4 steel has better mahinability with more content of S element.

Applications for 41Cr4 Steel

The 41Cr4, alloy structural steel is widely used in various industries based on specific properties which are suitable for components need high strength, good toughness, and wear resistance.

Automotive Industry

Auto parts like small shafts, pins, gear segments, spline shafts, bushings are commonly made from 41Cr4 steel. High fatigue resistance and strength of turned 41Cr4 steel is ideal for power transmission and its wear resistance is for sliding or rotating interfaces.

General Machinery

Machinery parts like small spindles, couplings, miniature gears, cams are made from 41Cr4 steel. The good machinability for precise dimensions, high hardness and wear resistance for reliable motion of 41Cr4 alloy steel are the main features for these applications.

Aerospace Industry

41Cr4 is used in making aerospace parts like small connecting rods, tooling inserts. The excellent strength-to-weight ratio and fatigue life for cyclically loaded engines and control components make it suitable material for aerospace applications.

Can 41Cr4 be Machined by CNC?

Yes, 41Cr4 steel can be machined well by CNC after quenching and tempering. In the untreated condition, the machinability of 41Cr4 is moderate. It means that its machinability is highly dependent on its heat treatment condition.

Machining in Annealed Condition

41Cr4 is relatively soft and ductile which improves its machinability in annealed condition. It is machined with high cutting speed and positive rake angles to get effective chip breaking. Typically, PVD-coated carbide inserts, high-speed steel tools are used in machining.

Machining in Quenched & Tempered Condition

Machining 41Cr4 in the quenched and tempered (Q&T) condition shows significantly greater challenges. This is due to its increased hardness and strength. It is machined with low cutting speed, aggressive coolant applications and strong and consistent feed rates. The cutting tools used in machining 41Cr4 are CVD-coated carbide and ceramic or cubic boron nitride (CBN) inserts. 41Cr4 is rarely machined on CNC in Q&T (Quality and Technical) mode, typically reserved for partial finishing or specialized applications.

Conclusion

41Cr4(EN 1.7035/DIN 1.7035) is a widely used EN standard chromium alloy structural steel. It is famous for its good balance of strength, toughness, and wear resistance after heat treatment. 41Cr4 alloy steel is cost-effective material for the applications in the machinery and automotive industries.

If you are looking for a reliable manufacturer that can manufacture steel parts with multiple threads or holes, you may probably choose Tuofa drilling machining service.

FAQ

What is Cr steel?

CR steel usually refers to Cold-rolled steel. It is hot-rolled steel which is further processed at room temperature for a smoother finish, tighter tolerances, and increased strength. Cr can also refer to Chromium addition in stainless steels.

Can 41Cr4 be nitrided?

Yes, 41Cr4 steel can be nitrided. However, it is quenched and tempered steel, not typical nitriding steel. Nitriding is used to increase its surface hardness and wear resistance for applications like gears and shafts.

What heat treatment methods are used for 41Cr4?

Different heat treatment methods like quenching and tempering (+QT), annealing (+A), normalizing (+N) are used for 41Cr4 chromium steel to achieve a balance of strength, toughness, and wear resistance.

What is 41CrS4 steel?

41CrS4 steel is a German standard low-alloy quenched and tempered steel, characterized by the addition of sulfur (S) to 41Cr4 to enhance its machinability.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What Is Oxygen Free Copper? A Complete Guide for You

What Is Oxygen Free Copper? A Complete Guide for You