Leaded Brass: A Properties, Grades, and Machining Guide

Jan 12,2026

Jan 12,2026

Huge numbers of metals and metal alloys are used in this world in multiple applications. At the end of the 18th century, Brass (Cu-Zn alloy) was commonly used in different applications. At the start of the 19th century, leaded brass was introduced because brass itself was not easy to machine. It was an evolution of CNC machining, due to which the machinability of metals meant a lot at that time. This article deeply focuses on leaded brass, its properties, grades, and applications.

What Is Leaded Brass

Brass is an alloy of Copper and Zinc, 60-65% Cu and 35-40% Zn. Leaded brass is an integrated part of this alloy, which is briefly defined below:

Leaded Brass Definition

Leaded brass is an integrated part of brass alloy with 1-3% Lead content. The defining property of this alloy is its excellent machinability, which simple brass lacks.

How to Tell If Brass Is Lead-Free?

The biggest identity of that is that leaded brass is easier to machine than lead-free brass. If the metal is requiring relatively higher cutting forces, then it is a lead-free brass, because if lead is present, machining of that brass will be very easy.

Typical Leaded Brass Composition

The typical chemical composition is as follows:

- Cu:55-65%

- Zn: 37-40%

- Pb:5 – 3.0%

- Fe: ≤ 0.35

- Sn:≤ 0.3

- Ni:≤ 0.3

What Is The Highest Lead Content Brass

Commonly, a brass can have a maximum 3% lead in its composition, for better CNC machinability. For example, UNS C36000 (free-cutting brass) typically contains 2.5–3.0 wt% Pb, while UNS C38500 can reach 2.5–3.5 wt% Pb under common standards.

In the real world machining process, machinists find that leaded brass with higher than 3 wt% lead make small improvement. Adding lead improves chip breaking and reduces cutting forces; so higher Pb is uncommon unless a specific grade/standard calls for it.

Leaded Brass Mechanical and Physical Properties

A metal or a metal alloy can be employed in an application if its mechanical and physical properties are known. The mechanical and physical properties of leaded brass are given below:

Strength and Hardness Range

The strength and hardness of the leaded brass are lower compared to other metals, because lead is spread along the grain boundaries in a spherical particle shape.

|

Property |

Typical Range |

|

Tensile Strength |

300–380 MPa |

|

Yield Strength |

95–125 MPa |

|

Hardness |

80–100 HB (Brinell) |

Ductility and Formability

Some properties, such as strength, formability, and strength are compromised in leaded brass to maintain the machinability. At room temperature, the formability of leaded brass is poor. For ductility, the elongation range is 10 – 25%.

Material Conductivity

Material conductivity can be thermal or electrical. For leaded brass:

Electrical conductivity: 25–30 % IACS (lower to moderate)

Thermal conductivity: 110–125 W/m·K

Machinability Rating

Lead is known for its lower hardness, softness, and ease of machining. The inclusion of 1-3% lead in the brass enhances its machinability greatly. So, leaded brass has excellent machinability.

What Is The Difference between Lead-Free and Leaded Brass?

As mentioned earlier, the main alloy is brass (Cu & Zn), but the leaded brass is its integrated part. This section will clarify the actual difference between an unleaded brass and a leaded brass.

Leaded Brass vs Brass

The biggest difference between the leaded brass and lead-free brass is the lead element, as the following table shows. The purpose of the inclusion of lead in the brass is to increase its machinability. The lead spreads along the GBs in spherical particle form, which makes machining softer and faster.

|

Element |

Leaded Brass (e.g., C36000) wt.% |

Brass (Cu–Zn, typical) wt.% |

|

Copper (Cu) |

57–61 |

60–70 |

|

Zinc (Zn) |

Balance |

Balance |

|

Lead (Pb) |

1.5–3.5 |

≤ 0.1 |

|

Tin (Sn) |

≤ 0.3 |

≤ 0.3 |

|

Iron (Fe) |

≤ 0.35 |

≤ 0.3 |

|

Nickel (Ni) |

≤ 0.3 |

≤ 0.3 |

Is Lead in Brass Safe to Use?

Mainly, it depends on the actual application whether leaded brass is safe to use or not. If the application is about plumbing fittings or potable pipelines, then leaded brass is not safe to use. Lead leaches out of the pipes into the water, which further causes cancer.

When Did They Stop Using Lead in Brass?

In the last decades of the 20th century, when health care departments figured out that lead in leaded brass water pipelines is the main cause of cancer, they imposed bans on the usage of lead in brass plumbing fittings. Lead is considered one of the most toxic metals.

Lead Concentration Limits

Lead is a toxic metal, which is why its concentration is limited. Electrical and electronic products are limited to a lead content of ≤ 0.1% (homogeneous materials), RoHS-compliant, and EU-certified.

For your projects, when leaded brass machined parts are required according to EU certifications and comply with RoHS, visit TUOFA CNC brass machining. We are a Chinese-based organization with the capabilities of CNC machining regardless of the material, such as soft metals - copper, aluminum, and hard ones -titanium, Inconel alloys, etc. We will provide you with tight tolerances, which will be EU-certified and RoHS-compliant.

Role of Lead in Brass Alloys

Lead is a very soft and dense metal. Its color is bluish-grey. It is malleable, corrosion-resistant, and used in many applications, but it is very toxic. Its fumes cause lung cancer. The role of lead in brass alloys is very important with respect to the applications. For instance, sometimes lead is added to brass when enhanced corrosion resistance is required.

How Lead Improves Machinability

Lead does not mix with Cu and Zn in brass. It remains insoluble and exists as discrete soft particles distributed along the grain boundaries. During the machining of leaded brass, these lead particles act as an internal lubricant, improving the machinability.

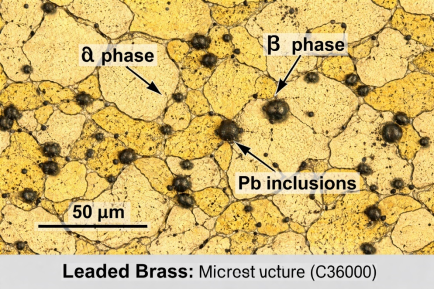

Microstructure of Leaded Brass

In the following figure, the discrete and insoluble lead particles are present along the GBs. These black spherical lead particles act as internal lubrication during the machining.

Limitations of Lead in Brass

- The biggest limitation of lead in brass is that leaded brass can't be used for potable water pipelines due to the ban and the causes of cancer. It is toxic, so it cannot be used for food packaging.

- Strength, formability, and hardness of the leaded brass are reduced, so it can't be used where strength is required.

Common Leaded Brass Designations

Leaded brass is available in mutiple designations, such as C36000, C85700, etc. Let's discuss some common designations of brass in this section of the article:

1. C36000 Free Cutting Brass

C36000 has the highest content of Lead (1.5% - 3.5%), which is why it is called free-cutting bass. The higher the lead content, the higher the machinability. It means this grade is very smooth for CNC machining. This grade is best for applications, such as:

- High-precision CNC machining

- Precision screws, fittings, and valves

- Bushings

- Complex turned components

2. C34500 Brass

In this leaded brass, the content of lead is higher than in free-cutting leaded brass, which means its machinability is higher, but other mechanical properties are compromised. For this grade, tool life increases due to reduced built-up edge. It is best for:

- Ultra high-speed automatic laths

- Electrical hardware

- Parts where machining efficiency is critical

3. C85700 Brass

It is a leaded yellow brass which has a moderate percentage of lead in its composition. It offers good castability with moderate machinability, so it is supplied in cast form. It is best for:

- Cast plumbing components

- Architectural hardware

- Decorative fittings

- Valve bodies

4. C38000 Brass

It has a lower lead content compared to C36000, so the machinability is compromised, but it offers good mechanical properties. It is known as low-leaded brass. It is best for:

- Automotive fittings

- Machined-and-formed parts

- Light structural parts

5. CuZn39Pb3 Brass

It is considered equal to C38500. It comes with up with 3% lead, so the machinability is close to C36000. It is best for:

- Extruded bars

- Machined fittings

- Architectural parts

- profiles

6. Naval Leaded Brass

For marine and corrosive environments, naval leaded brass is used.

- C48500

It has tin alongside lead for enhanced corrosion resistance. Due to tin, machinability is lower than that of C36000. It is best for:

- Pump components

- Fittings exposed to seawater

- C46400

It has higher tin content and lower lead content than that of C48500. So, the machinability is decreased, but corrosion resistance is increased.

It is best for:

- Condenser plates

- Shipbuilding components

- Marine fasteners

Other Lead Materials

Other leaded brass metals, such as C83600 is a little bit different than a true brass. It is often referred to as a leaded brass, but it has lower zinc content and higher lead and tin. It is best for:

- Bearings

- Valve bodies

- Pressure-retaining castings

Where to Use Leaded Brass Commonly

Although leaded brass cannot be commonly used in electrical and electronic equipment due to RoHS restrictions, it still has many applications in important fields, such as:

Marine Components

Marine components are those that consistently remain in the seawater. Leaded naval brass is used in multiple machine parts. It is used in:

- Seacock bodies and valves

- Through-hull fittings

- Pump housings and pump connections

- Impeller hubs and small pump fittings

- Marine pipe fittings and adapters

- Drain plugs

- Hose barbs and couplings

Fasteners and Fitting

Leaded brass is used in fasteners and fittings, not due to strength, but its selection is mainly due to manufacturing efficiency and dimensional accuracy. It is used in:

- Screws

- Nuts

- Threaded inserts

- Studs and small threaded pins

- Pipe fittings

- Compression fittings

- Hydraulic and pneumatic fittings

- Instrumentation fittings

Precision Turned and Machined Parts

In manufacturing industries, leaded brass stands tall when it comes to ease of machining and achieving tighter tolerances. For precision turned and machined parts, lead-induced microstructure plays an important role. It provides excellent machinability, which leads to achieving tight tolerance, smooth surface finish, and cheaper high-volume production.

Leaded Brass in CNC Machining

Till now, it has been discussed multiple times that leaded brass is a highly machinable alloy. This section of the blog describes it:

CNC Machinability of Leaded Brass

Leaded brass has 1-3% of lead in its composition. It does not mix with the matrix of Cu and Zn, but remains in the form of spherical lead particles along the GBs. During CNC machining of leaded brass, these particles become like lubrication, due to which cutting forces are reduced and speed is increased. That is why it shows excellent machinability for CNC machining, which further leads to tight tolerances, excellent, and durable surface finish.

Typical CNC Brass Parts

Typical CNC brass parts mean the parts are produced using CNC machine operations, such as turning and milling, etc. These parts include screws and set screws, special precision nuts, threaded inserts, hydraulic and pneumatic adapters, contact sleeves, connector pins and terminals, bushings, and spacers, etc.

How to Machine Leaded Brass Alloy?

The machining of leaded brass alloy is a process of multiple operations, such as turning, milling, and drilling, etc.

Precision CNC Turning Brass

The precision CNC turning process is used when the parts are spherical. A tight tolerance of ±0.01mm can be achieved. Through this process, these parts are manufactured:

- Nozzles and valve components

- Hose barbs and couplings

- Bushing, sleeves, and spacers

- Compression fittings and ferrules

Precision CNC Milling Brass

The precision CNC milling process is used for leaded brass components when the geometry of the part is complex. The process is helpful in the manufacturing of the following parts with ±0.01mm dimensional accuracy.

- Manifolds and distribution blocks

- Electrical connector housings

- Brass Terminal blocks

- Pump cover plates

- Custom-machined parts

Tapping and Drilling

Drilling

This process is used for making holes in the brass parts, such as in plates, for joining through the nuts and bolts.

Tapping

For internal and external threads, like in brass screws and nuts, the tapping process is used.

Design Tips for Leaded Brass Machining

- Avoid unnecessary tight tolerances in the design

- Try to remove stress-concentrator points if present

- Avoid sharp edges or corners

- Try to increase the thickness if it is not critical because of the lower strength of leaded brass

Leaded Brass vs Other Metals

There are multiple metals used in different applications. So it is not easy to compare leaded brass with all of these metals. Leaded brass is different from many angles compared to stainless steel, aluminum, and brass itself.

Leaded Brass vs Stainless Steel

Stainless steel is a very strong and highly corrosion-resistant metal compared to leaded brass. It has hundreds of grades differing based on corrosion resistance and strength. Stainless steel is employed in structural, potable, and marine applications. Its machinability is lower compared to leaded brass.

Leaded Brass vs Aluminum

Al and its alloys are used in many important applications, like aerospace and electrical wires. Its corrosion resistance is excellent due to a passive layer on its surface. It is stronger than leaded brass, but its machinability is lower compared to leaded brass.

How to Choose The Right Leaded Brass Grade?

The grades of leaded brass are different based on corrosion resistance, machinability, and strength. All of these differences are made by altering the chemical composition. For instance, where the strength is the primary requirement, leaded brass with higher Zn content is preferable.

Conclusion

Leaded brass is an integrated part of brass that has a higher percentage of lead content, typically in the range of 1.5% - 3.5%. The purpose of lead is to increase the machinability. Since the lead spherical particles do not mix with the Cu and Zn matrix, they spread along the grain boundaries and act as internal lubricants during machining. Leaded brass is available in multiple designations, such as C36000, C34500, etc. They are different based on the percentage of lead, so the machinability. Leaded brass is used from simple valve bodies to marine components, which shows its importance.

FAQs About Leaded Brass

Does old brass contain lead?

No, at the end of the 18th century and the start of the 19th century, lead was induced in brass to make its machining easier.

Can you remove lead from brass?

No, it is neither economically nor it is practically possible. The lead particles are physically trapped along the GBs.

Do all brass faucets contain lead?

No, modern brass faucets are made under strict lead inclusion limitations. Maybe older faucets have significant lead content.

Does yellow brass have lead in it?

No, the color of brass does not mention whether it is leaded or lead-free. To check if it is leaded brass, please refer to certifications and specific grade designation.

When should I choose leaded brass?

When smooth surfaces and tight tolerances in the dimensions with lower strength are required, you should choose leaded brass.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What is 41Cr4 Steel? Everything You Should Know

What is 41Cr4 Steel? Everything You Should Know