Powder Coating vs Galvanised Steel: Choosing the Right Finish

May 30,2025

May 30,2025

You know that the surface of the object is very important. If it is not maintained well, issues such as oxidation, corrosion and fatigue failures can happen. To avoid surface-related issues, we use surface treatments. Powder coating and galvanising are surface treatments. This article presents you with a comprehensive guide about powder coating and galvanising, covering all their perspectives, like suitable materials and applications, etc.

What Is Powder Coating?

Powder coating is a process of ceramic coating. In this process, the powder is electrostatically charged, sprayed onto the metal substrate, and then cured at a very high temperature. This coating is highly resistant to high temperatures, wear, etc.

Powder Coating Process

These are the following processes which are used in the powder coating process:

- Spray

Powder is stored in the gun and gets melted due to the high temperature of ionised gas in that tube. Using a spraying gun, powder is fired at the substrate.

- Cure

Curing involves baking and melting the powder on the substrate.

- Film-Build

The thickness varies based on the time of spraying powder; the average achieved thickness is 50-250 microns.

Typical Powder Chemistries

Powder coating is not a simple process, but chemistry plays a significant role in this process:

- Polyester

It is an ideal coating for outdoor applications because of its UV-resistant capability.

- Epoxy

If you need toughness, you can use this coating material, but it is prone to UV degradation easily.

- Hybrid

You can use it for both toughness and UV-resistance.

Common Metals That Can Be Powder-Coated

Powder coating is not ideal for every metal. Some commonly powder-coated materials are stainless steel, aluminium and steel.

What Metals Cannot Be Powder Coated?

If you have non-conductive materials which do not show strong adhesion, they are not considered suitable for powder coating materials. These materials include wood, plastic and zinc, etc.

What Is Galvanising?

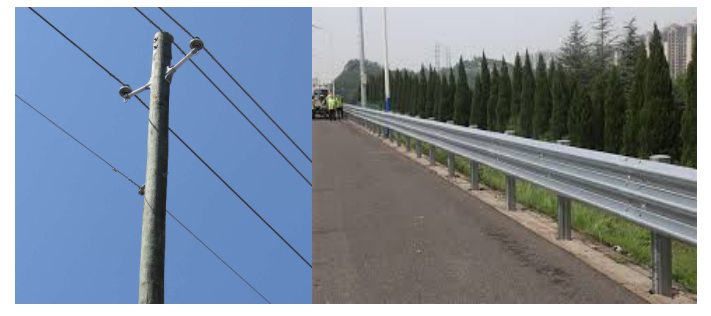

Galvanising is the process of depositing a molten Zn layer on the metal to protect it from corrosion in normal conditions. The most common application of galvanising is the barriers on the road.

Hot-Dip vs. Electro-Galvanising—How They Differ

Hot-Dip Galvanizing

If you dip your substrate in the bath of molten Zn and a Zn layer is deposited on the substrate, then it is called hot-dip coating. It is used to deposit thick Zn layers on the substrates.

Electro-Galvanizing

If you want to deposit a thin and smooth Zn layer, you should perform electro-galvanising. Zn layer is deposited through electricity.

Zinc Layer Formation and Self-Healing Effect

You will be amazed to know that the Zn layer is a self-healing layer. From the scratches, Zn reacts with oxygen and a layer is again formed.

Metals Most Often Galvanised

These are the most galvanised metals:

- Mild Steel

It is used in construction and side barriers on the roads, etc.

- Cast Iron

It is mostly used in heavy-duty applications.

Powder Coating Steel vs Galvanised Steel: Key Performance Factors

This section provides you with brief but informative data, like how powder coating is different from galvanising.

Corrosion Resistance & Outdoor Life

Galvanizing

Due to the self-healing ability of the Zn layer, it can last for decades, but not in harsh conditions. It means you can confidently use this for long-term applications.

Powder Coating

It is mainly used for high-temperature applications, which resist oxidation, etc. It can last for 14-15 years easily.

Salt-Spray Hours and Real-World Lifespan

In real-world applications, galvanised steel shows salt-resistance for 100+ hours while powder coating provides resistance for 600-1000 hours.

Mechanical Durability

The following table shows that galvanised steel will perform best in impact-resistant applications, but powder coating is used only for aesthetic purposes.

|

Factor |

Powder Coating |

Galvanized Steel |

|

Impact Resistance |

Moderate – may chip or crack under heavy force. |

High–zinc layer absorbs shocks, reducing dent risk. |

|

Scratch Resistance |

Low to moderate – scratches show but can be touched up. |

Moderate – zinc scratches but "self-heals" via oxidation. |

|

Abrasion Resistance |

Good – durable but wears faster than galvanising. |

Excellent – zinc layer withstands friction better. |

Appearance & Colour Options

You can have any desired colour in powder coating, while galvanising provides a silver-grey colour.

Texture, Gloss, and Patina Potential

If you want flexibility in design, go for powder coating because patina limits colour and aesthetic appeal in the design.

|

Feature |

Powder Coating |

Galvanized Steel |

|

Texture |

Smooth or custom textured |

Naturally rough/spangled |

|

Gloss |

Fully customizable (matte to gloss) |

Fixed metallic sheen |

|

Aging |

Colour stays stable |

Develops white patina over time |

Thickness, Tolerances, and Part Distortion Risk

The following table summarises information about these factors:

|

Factor |

Powder Coating |

Galvanized Steel |

|

Thickness |

2-10 mils (50-250μm) |

3-8 mils (75-200μm) |

|

Tolerances |

Maintains tight tolerances |

May affect tight tolerances |

|

Distortion Risk |

Minimal |

Moderate |

Cost Analysis Over Product Lifetime

We will discuss the cost difference between powder coating and galvanising in this section:

Up-Front Processing Costs

Up-front costs show that for small batches, powder coating is cheaper than galvanising.

|

Cost Factor |

Powder Coating |

Galvanizing |

|

Prep |

5−15$/sqft (cleaning, blasting) |

2−8$/sqft (degreasing, pickling) |

|

Equipment |

50k-200k (spray booths, ovens) |

$ 1 M+ (zinc baths, cranes) |

|

Labor |

20−50$/hr (skilled technicians) |

15−30$/hr (less specialised) |

Maintenance & Recoating Expenses

Due to the self-healing effect, galvanising requires low maintenance costs. Recoating expenses for powder coating are lower than for galvanising.

Hidden Costs

Some hidden costs include shipping, masking, rework and downtime. They are considered secondary important factors for the cost analysis.

Environmental & Safety Considerations

Some environmental and safety considerations are:

VOC-Free Powder vs. Molten-Zinc Fume Controls

Powder coating does not produce volatile organic carcinogens, but galvanising produces Zn fumes, which cause lung irritation.

Energy Consumption and Carbon Footprint

Galvanising consumes more energy as compared to powder coating. The carbon footprint is produced 3 times more in galvanising.

Best-Fit Applications for Powder Coating vs Galvanised Steel Finish

In this section, you will learn for which application you should apply either powder coating or the galvanising method.

Where Galvanising Excels

For outdoor applications such as utility poles and guard rails, you should choose galvanising because it provides high corrosion resistance.

Where Powder Coating Shines

In applications, such as architectural panels or EV frames, you need aesthetic appeal. In that scenario, prefer powder coating.

Combined Systems

There are many applications which use a combined system of powder coating and galvanising. These applications are bridges, marine equipment, etc.

Pros & Cons of Powder Coating vs Galvanised Steel

You may have benefits or problems by using a combined system. Let’s figure out both here:

Benefits of Powder Coating Galvanised Steel

You will have excellent corrosion resistance and aesthetic appeal. Strength will be increased as well.

Problems with Powder Coating Galvanised Steel

- Adhesion issue

- Hydrogen embrittlement risk

- Thermal stress mismatch

Decision Checklist: How to Choose the Right Finish

For further help in choosing between galvanising and powder coating, read this section as well.

Climate & Exposure Conditions

If conditions are harsh or exposure to normal rain, etc., then galvanising will do its job perfectly in this scenario.

Aesthetic and Branding Requirements

If you need aesthetic appeal in your product, choose powder coating without any hesitation.

Regulatory or Industry Standards

The following are some standards which cover galvanising and powder coating, respectively.

ASTM A123

- Used for hot-dip galvanising

- Provides information related to thickness, adhesion and appearance

AAMA 2605

- Used for powder coating

- It guides salt resistance, colour retention and chalk resistance

Conclusion

We conclude that powder coating and galvanising are surface treatments which are used to increase surface durability. Galvanising is helpful for corrosion resistance, but powder coating excels in design flexibility requirements and aesthetic appeal. If you want to choose the right surface treatment for your custom project, TUOFA CNC Precision Machining is a good choice!

FAQs

Can powder coating be applied over galvanised steel?

Yes, if you need corrosion resistance and aesthetic appeal on the same object, you can use a combined system of powder coating and galvanising.

Which finish lasts longer in coastal environments?

Galvanising remains for 30-40 years easily in coastal environments.

How long will powder-coated steel last outside?

Powder-coated steel can last for 10-12 years in outside applications.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

How to Prepare a DXF File for Machining? -Complete Guide

How to Prepare a DXF File for Machining? -Complete Guide