Types of Metal Finishes: Machined Parts Finish

May 29,2025

May 29,2025

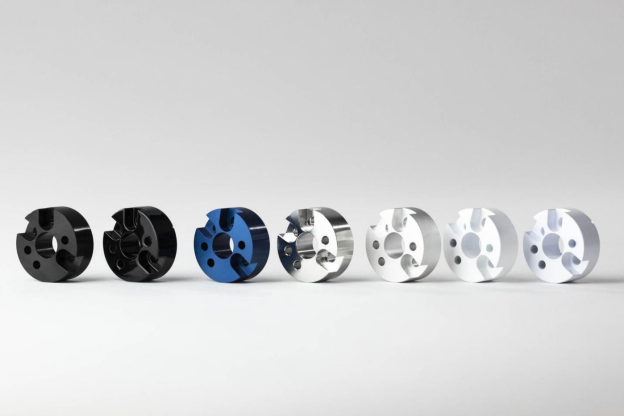

When you use machined parts directly after machining in your applications, the rate of corrosion or fatigue, etc., will be high, leading towards ultimate failures. So, even after complete machining, we use metal finishes which enhance the durability of surfaces. In this article, you will learn about different metal finishes. At the end of this article, choosing a specific metal finish for your respective application will be easy. So, let's begin with a brief introduction to metal finishes.

What Is Metal Finishing for Machined Parts?

CNC machined parts have although very fine surface finishing, but are still not durable for corrosion resistance in even normal conditions. We use different surface treatments, such as galvanising, to make a protective layer on the machined parts' surface.

Metal Finishing After Machining

The basic requirement of metal finishing after machining is to enhance surface durability by increasing corrosion resistance. Secondly, metal finishes provide different colours which make machined parts aesthetical.

Why are Surface Finishes Important for Machined Components?

Surface finishes provide resistance against wear and corrosion, and an aesthetic appearance. The following table shows different finish types with their purposes:

|

Finish Type |

Purpose |

|

I. Anodizing |

Corrosion resistance, aesthetics |

|

II. Powder Coating |

Durability, colour options |

|

III. Passivation |

Rust prevention |

|

IV. Electroplating |

Wear resistance, conductivity |

|

V. Bead Blasting |

Uniform texture |

|

VI. Electroless Nickel Plating |

Wear/corrosion resistance, uniform coating |

|

VII. Chromate Conversion Coating |

Corrosion protection, paint adhesion |

|

VIII. Black Oxide |

Mild corrosion resistance, aesthetic black finish |

|

IX. Grinding |

Precision surface smoothing |

|

X. Brushed Finish |

Decorative, scratch-hiding texture |

Surface Treatment Selector

Nickel Plating

Conversion

Coating

Finish

How Metal Finishing Enhances Machined Parts

This section gives you insights into why we can't go without metal finishing and how they enhance machined parts' durability.

Improving Corrosion Resistance

A metal finish process, let's say galvanising, provides a protective layer of Zn on the surface of the machined part. This layer is now a barrier between the surface and the environment, so corrosion increases in this way.

Enhancing Surface Hardness and Wear Life

Metal finishes provide nitrides or chrome plating on the surface, which increases hardness and ultimately increases wear life.

Better Appearance for Visible Parts

If you need a better appearance for visible parts, you will have to use a metal finishing process like polishing or powder coating.

Meeting Functional Surface Requirements

If your machined parts have to be employed in electronics or medical implants, you will still need to use metal finishes like gold plating, etc.

What Are the Different Types of Coatings on Metal?

Metal finishes are divided into three main categories, which you will study in this section of the article.

Additive Coatings (Electroplating, Powder Coating)

In additive coatings, a coating is prepared by depositing material layer-by-layer on the substrate. Additive coatings are of two types:

- Electroplating

- Powder Coating

Conversion Coatings (Anodising, Passivation)

In this type of metal finish, you alter the base metal's surface into a protective layer through a chemical process. The following are the main types:

- Anodizing

- Passivation

Mechanical Finishing (Polishing, Blasting, Grinding)

This process is quite different from chemical or additive coatings. You change the material's surface using force, like you change the texture of the surface, etc. Its examples are:

- Polishing

- Blasting

- Grinding

Electroplating and Electroless Plating for Machined Parts

You can use this metal finishing process only for conductive materials. You deposit any material on the base metal through an electric current. Electric current makes the surface conductive, so the ionised coating material falls on the conductive base metal's surface.

Electroplating: Common Metals Used

These are some common metals which you can use for electroplating:

|

Metal |

Thickness Range |

Primary Applications |

|

Nickel |

5-50 μm |

Wear resistance, corrosion protection |

|

Zinc |

3-25 μm |

Sacrificial corrosion protection |

|

Chrome |

0.3-5 μm |

Decorative and hard chrome applications |

- Which metal cannot be electroplated directly?

Some metals cannot be electroplated directly, such as aluminium and its alloys, which instantly react with oxygen and make Al2O3. This oxygen layer leads to poor adhesion for other layers.

Barrel Zinc Plating for Small Parts

It is an electroplating process through which you can apply a Zn layer on small conductive parts efficiently. It is used for mass-finishing purposes.

Electroless Plating: Advantages for Complex Machined Geometries

The biggest advantage of this process is that you can efficiently coat intricate shapes without electricity.

Applications: Electrical Connectors, Aerospace Components

Its applications are common in electrical connectors and aerospace components, such as Titanium (Ti-6Al-4V) fasteners are nickel plated using an electroless plating process.

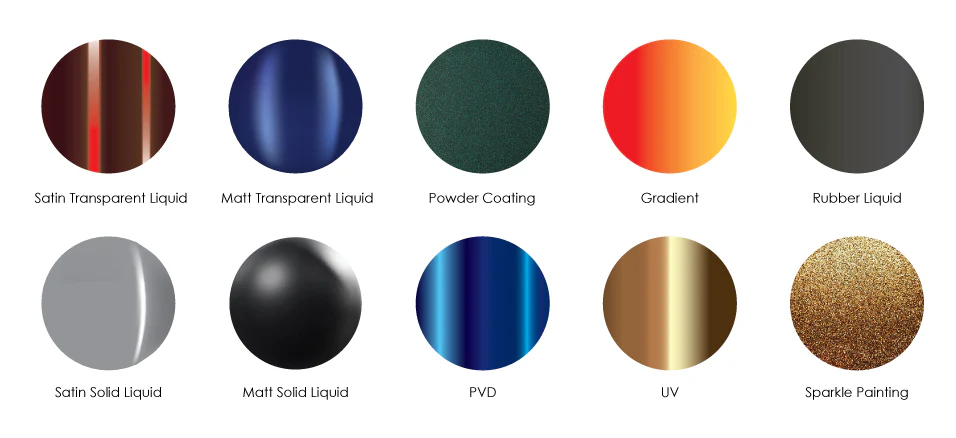

Powder Coating and Painting Options

The type of metal finish process, in which coating powder is applied on the substrate's surface through an electrostatic process. This process is the opposite of the painting process, in which coating material is mixed in liquid first, then it is coated. Some painting options include dip coating, spray coating, electrostatic wet spray, etc.

Powder Coating Colours Types

Every colour of powder coating has its purpose, such as:

- RAL Classic: used for safety components, it has 190+ colours

- Other systems include Pantone matching (2300+ colours) and special metallic finishes, etc.

Benefits of Using Powder Coating

Powder coating offers you the following advantages:

- Enhanced durability

- Good environmental resistance

- Cost-effective

- Very low waste of coating material

When Liquid Painting Is a Better Choice for Machined Parts

If you need thin films, the geometry of the part is complex, and the substrate is temperature-sensitive, then you should choose liquid painting options.

Coating Thickness

Through powder coating, you can form thick coatings, i.e. 60-120μm. While you can form thin films of up to 15-50μm thickness using liquid painting options.

Surface Protection Considerations

Powder coating provides better corrosion resistance as compared to liquid painting systems. Experiments show that a powder-coated substrate can handle 500 salt-hours easily, while liquid-painted substrates suffer durability issues.

Anodising and Passivation Treatments

Anodising

The protective oxide layer is deposited on the substrate through an electrostatic process.

Passivation

A protective and non-reactive layer is formed on the substrate using chemical or surface treatments. Sometimes, natural oxidation is used as well.

Anodised Aluminium Parts

Mostly, these anodised aluminium parts are used in aerospace applications because of the high hardness of anodised films.

Anodised Titanium Machined Parts

These parts are used in medical implants because of their biocompatibility, high hardness and wear resistance.

Passivation Stainless Steel Machined Components

You can use passivated stainless steel machined parts in surgical tools and food equipment.

Better or Thicker, With These Surface Finish Treatments?

Often, you hear the phrase “Quality not Quantity”. The same is the case with Anodising or passivation like although the coatings are not so thick but of high-quality. It provides high corrosion resistance, hardness and wear resistance. Because of its lightweight features, we use anodised parts in the aerospace industry. Anodised films are highly durable.

Mechanical Surface Finishing for Machined Parts

Mechanical surface finishing means you mechanically, i.e. using abrasive or cutting force, alter the surface of the object. In this section, we will briefly discuss some mechanical surface finish-related operations.

Finishes for Surface Texture Control

The following are the operations we use to make the texture of the surface according to our requirements. These operations are specifically used for stainless steel, aluminium and titanium machined parts:

- Brushed Metal Finish

In this process, you can use wheels or billets to get a linear grain pattern texture of the surface. You can achieve a surface roughness of 0.4–1.6 μm. Its common applications are found in panels, architectural trims, etc.

- Satin Metal Finish

If you want a low-glare texture with surface roughness of 0.2–0.8 μm, you can use uniform abrasive treatments, e.g. Scotch Brite belts. This metal finish is used in medical instruments and food processing equipment.

- Matte Metal Finish

If your machined components need to have a non-reflective and frosted appearance, perform blasting using fine glass beads. This process will provide you with 0.1–0.4 μm Ra and is used in optical instruments and military instruments.

Brushed vs. Satin vs. Matte Metal Finish

The following table shows a comparison among these finishes based on two surface-related properties.

|

Characteristic |

Brushed |

Satin |

Matte |

|

Reflectivity |

Directional sheen |

Soft glow |

Non-reflective |

|

Fingerprint Hiding |

Poor |

Moderate |

Excellent |

Finishes for High-Gloss Appearance

High-gloss appearance means a very shiny and reflective surface. If you need such a surface, use these processes:

Polishing and Buffing

Polishing

Abrasive papers (from larger to smaller numbers) are used until the mirror-like finish is achieved.

Buffing

You can use cotton wheels with compounds for final lustre. Some common compounds are white rouge for stainless steel and green rouge for Titanium.

Uniform Surface Cleaning

During machining, some scratches often remain behind on the surface, which become stress risers during applications and ultimately failures. That is why the following processes are performed to get a uniform surface of the object.

- Bead Blasting

The substrate is hit by a lot of fine glass beads to get a uniform surface of Ra 1.5–3.2 μm.

- Abrasive Blasting

In some applications, like in the case of painting, you will need a rough surface. Aluminium oxide balls are smashed on the substrate.

Electropolishing

For ultra-smooth, contaminant-free surfaces, you can perform electropolishing. Its common applications are the semiconductor industry and pharmaceutical equipment.

Choosing the Right Metal Finish for Your Machined Part

Until now, we have discussed many metal finish processes, but we cannot use them blindly. There are some criteria or factors which decide the suitability of the respective metal finish techniques. This section will help you learn how to select a specific metal finish for your machined part:

Key things to consider:

These are the key factors that affect the suitability of the metal finish process.

- Corrosion-Prone Environments: see if the environment is harsh, like sea water, then use the anodising metal finish process.

- Function: You should have an idea of what function you need from the finish, like if you need a mirror-like finish, perform electropolishing.

- Level of finish required:If you are going to use a machined part for painting, then for a rough surface, use abrasive blasting.

Base metals: Aluminium, Steel, Brass, Titanium, etc., are compatible with different metal finish techniques. You should have an idea of their surface-related properties, i.e., reactivity.

- Prep work required:see if you need some preparation work for the respective metal finish process.

- Cost: Probably the most basic factor, you should know your budget first before choosing the metal finish process.

TUOFA one-stand solutions for machined parts, from design to machining, to a perfect surface finish. We will provide our services most cost-effectively compared to other companies.

Applications of Metal Finishing in Machined Part Industries

In critical industries such as aerospace, metal finishing processes have significant importance because they provide durability to machined parts. Let's discuss some important applications:

Aerospace and Defence Precision Components

Al alloys, such as 2024-T3 Al alloy, are anodised and used in aircraft structure components. Ti alloys (Ti-6Al-4V) are anodised for the applications of corrosion-resistant fasteners.

Automotive Engine and Transmission Parts

Steel alloys, e.g. 4140, are Zn-Ni plated with bolts. Al alloys like A380 are powder and used in valve covers.

Electronics and Communication Hardware

- Cu alloys, e.g. C11000, are gold plated for RF connectors

- Al alloys, e.g. 5052, are anodised for EMI shielding

Pros and Cons of Different Metal Finishes

Let us discuss what advantages and disadvantages you can have using metal finishes for your machined parts.

Advantages

- Protection: against corrosion and wear

- Aesthetics: metal finishes make your machined parts more beautiful because of the colours and smoothness.

- Functional performance: metal finishes are helpful to get functional properties such as conductivity and reflectivity.

Limitations

Cost: Some metal finish techniques, such as electroless nickel, are very expensive.

Processing time: these metal finish techniques can be slower, e.g. it takes 3-4 hours for hard anodising.

Material restrictions: Not every material is compatible with any metal finish technique, i.e. thermoplastics are not compatible with electroplating.

Conclusion

There are many metal finish techniques which we use in our daily routine for our machined parts. These metal finishes are responsible for enhanced corrosion and wear resistance, aesthetics and functions like conductivity. In TUOFA CNC precision machining shop, we have been provide kinds of metal finishes to many custom projects. We choose any metal finish techniques according to custom required surface finish, such as if a non-reflective surface finish is needed, we will choose the blasting technique. Not every material responds well to every metal finish technique.

FAQs

What is the best metal finish for CNC-machined parts?

It depends on the required property you need from the surface. If you need adhesion, a rough surface is best in that scenario.

Can multiple finishes be combined on a single machined part?

Yes, we often first bead-blast our machined part, then anodising is performed. Now, you will have a texture and colour.

What is the most durable finish for metal?

The metal finish, which provides exceptional corrosion and wear resistance, is considered the most durable finish. Hard chrome plating is one of them.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Powder Coating vs Galvanised Steel: Choosing the Right Finish

Powder Coating vs Galvanised Steel: Choosing the Right Finish