Powder Coating Removal: Removing From Metal& Plastic

Apr 28,2025

Apr 28,2025

Powder coating is a surface finish process to enhance metal surface features by applying protective layer. However, powder coated material may require removal for repairing and restoring of original surface. In this article, we will know about the was to remove powder coating from metal and plastics and pros and cons of each ways.

What Is Powder Coating?

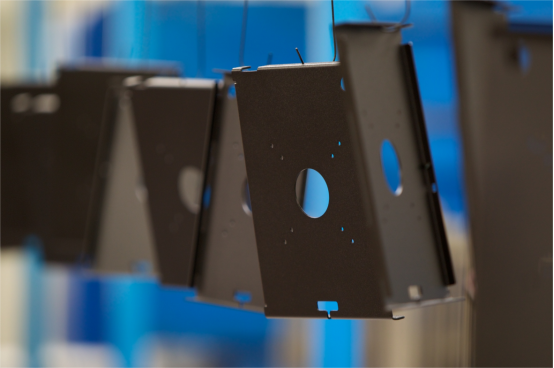

It is a dry surface finish process in which powder is applied to the surface with electrostatic charge. This powder coat is then cured to get a durable protective layer. This is a high-quality finishing layer and improves corrosion, resistance of material.

Powder Coating In Metals

Metals like Aluminum, titanium, copper, brass, bronze, steel and stainless steel are widely powder coated to increase rust, scratch and impact resistance. This layer creates a strong and long lasting barrier and shields the metal. It also offers decorative finish to the final product with customization of color and style.

Powder Coating In Plastic

Plastics like polysulfone, glass fiber and carbon fiber, ABS, PVC and polycarbonate are powder coated to increase their durability, impact and scratch resistance and to protect it against UV degradation and extreme weather and temperature conditions.

Why and When Do You Need to Remove Powder Coating?

There are a few reasons where it is necessary to remove powder coating. These are explained below:

Common Reasons for Powder Coating Removal

One of the common reasons for powder coating removing are repairing and restoring the original surface and to address issues with adhesion an curing.

Refinishing and Repainting

Refinishing the original surface with further treatments like applying a new coat or welding requires powder coating removing. And if someone wants to customize the product by repainting with different color, style or textured, require the removal of existing coating

Repairing Damaged Surfaces

Damages like crack, chips require powder coating removing to repair the original surface. In some cases, if coating is not adhered properly, flake or bubbles are created which also need coating removal to repair the surface.

What Happens if Powder Coating is Not Removed Correctly?

If powder coating not removed correctly, it can damage the base layer of metal and subsequent coating ma not adhere. This creates peeling, chipping and poor quality of new coating.

Issues with New Coating Adhesion

Issues with new coating adhesion occur due to improper surface preparation or poor application technique which results in peeling, blistering and chipping of new coating.

Surface Damage and Compromised Durability

Use of improper methods like abrasive tools and harsh chemical during powder coating removing can create scratches and weaken the underlying layer.

The Easiest Way to Remove Powder Coating: Chemical Stripping

Chemical stripping is considered as a easy and commonly used way to remove powder coating. Its details discus below:

What is Chemical Stripping and How Does it Work?

It involves using chemical solution to dissolve, soften or swell the powder coating to peel off or wash away from the metal surface.

Types of Chemical Strippers

Solvent-based contains methylene chloride that dissolve the powder coating like Benco-B17 used as industrial or automotive stripping solution, acetylene or ethyl alcohol. While caustic strippers break down the organic material with alkaline like sodium hydroxide. Other chemicals like biochemical and acidic stripper are also used

How to Safely Use Chemical Strippers

It is necessary to wear PPE, ensure proper ventilation and follow instruction for applications and disposal provided from manufacturers. A brush or dripping method is used with stripper left for a sometime before scraping the powder coat.

Pros and Cons of Chemical Stripping

Each method has its own advantages and limitation. Chemical stripping has pros and cons which are:

Advantages

- It effective dissolve and remove powder coat with minimal or no harm to original layer

- The method mostly gives consistent results of powder coating removing

- It is overall a cost-effective method require less capital and manual labor

Risks and Hazards

- Solvent based stripper have a potential health risk from toxic fumes.

- Use of solvent can contribute to enviromental pollution

- This method can take time than other methods like heat removal or blasting

Best Chemicals for Powder Coating Removal

Benco B-17 is highly recommended as it can remove coating under 20mints. Klean strip or generic acetone can also be used for DIY powder coating.

Acetone vs. Other Solvents

Acetone like methylene chloride is the most effective chemical while acetone is comparativly less effective. However, methylene chloride has been replaced by benzyl alcohol due to safety measures.

Choosing the Right Chemical for Different Materials

For metal, Benco B17 and Tri-sodium phosphate are used. For composite and polymers, specialized stripper or other method like heat and abrasive blasting are used.

Thermal Stripping: Using Heat to Remove Powder Coating

Thermal stripping is an another common method to remove powder coating. Detail of this process are as:

How Thermal Stripping Works: Heat and Burn-Off Process

It involves using high heat to break down the coating and convert it to ash to be removed easily. It is also called burn-off process.

Equipment Needed for Thermal Stripping

It is carried out in industrial ovens that can reach temperature up to 600-1200°F or on fluidized bed system for large part and heat guns are used for smaller parts.

Safety Precautions When Using Heat

Safety kits like PPE and proper ventilation system are required to avoid potential hazards like toxic fumes and hot surfaces.

Pros and Cons of Thermal Stripping

The pros and cons of this method are as:

Advantages

- It is relatively a faster process for large volume

- Ashes are removed by rinsing of water which eliminates a need of chemical disposal.

Disadvantages

- It require specialized equipment like high-temperature oven which is expensive

- It is not suitable for all type of material like soft metal and heat-sensitive material

What Temperature is Required for Powder Coating Removal?

A minimum temperature required to burn-off the powder coat is 650°F and maximum 1200°F. but for heat sensitive materials like polymers or aluminum alloys, it must not exceed from 200°F.

Abrasive Blasting for Powder Coating Removal

It is also one of the effective method for powder coating removal.

How Does Abrasive Blasting Work for Powder Coating?

The pressurizes air or water is used to propel abrasive particle against the surface. This breaks down and remove the coating from the metal.

Wet vs. Dry Abrasive Blasting

Wet abrasive blasting is preferred over dry blasting. It is because of ability to cool the surface, create smoother surface by preventing warping and is a more controlled process. Dry blasting is also effective for power coating removal but heat can cause issues in thin metal and heat sensitive material.

Media Options for Effective Blasting

Different abrsive media like glass beads, aluminum oxide or garnet are used. The provide a good removal power and create textured surfaces. Adhesion is also better with these option for subsequent coating.

Pros and Cons of Abrasive Blasting

The pros and cons of this method are as:

Benefits

- it is a cheaper process than other methods and effective for large quantities

- It creates a surface profile that provides better adhesion for new coating

- It is a versatile process for different applications and can be done in single step

Risks

- It requires a manual control and is a time-consuming and labor intensive process.

- It can erode soft metal if not done properly

What Surfaces Can Be Safely Blasted?

It is considered safe for metals like steel, aluminum and other alloys but sometimes not suitable for plastic and composite due to being soft materials.

Laser Powder Coating Removal: The High-Tech Solution

It is a precise and environmentally friendly process of coating removal.

How Does Laser Powder Coating Removal Work?

A laser beam is used to vaporize the powder coat which leaves the metals surface clean and intact. It is particularly used for localized ares and has many advantages over traditional method like chemical stripping and abrasive blasting.

Laser Types for Powder Coating Removal

Laser types like single-mode and multi-mode laser are used. Single-mode has better beam quality and can etch the surface and provides better adhesion after cleaning. Multi-mode has a faster cleaning speed

Pros and Cons of Laser Removal

The pros and cons of laser removal are as:

Advantages

- It is a precision and controlled process and does not damage the substrate.

- It is an environmentally friendly method and require no additional clean up

- It is an easily automate process and effective for high-volume

Disadvantages

- It is not ideal for large area and is only preferred for localized areas.

- Heat disposal during removal can damage the coating or material

- It is overall an expensive process than other methods.

When Should You Choose Laser Powder Coating Removal?

It is preferred when there is a need of precise and efficient removal for localized area or delicate material. It has minimum damage to the underlying materiel

How to Remove Powder Coating from Different Materials

Each material behaves different during powder coating removal due to different level of heat sensitivity,strength and durability of material.

How To Remove Powder Coating From Aluminum?

Considering the melting temperature and strength of aluminum, heat, chemical and abrasive removal methods can be used.

Step-to-Step Guide:

- Prepare the surface to remove any dirt

- Apply chemical stripper on the area using brush or spray or dipping the part

- Allow soak time up to 10-20 minutes

- Scrape and remove the softened powder by scraper, brush or wire

- Rinse and clean the final surface from water or degrease it.

How To Remove Powder Coating From Steel?

Powder coating removal from steel can be harder due to strong bond with the base layer. However, all methods can be used to remove coating.

Step-to-Step Guide:

Chemical stripping is done by

- Cleaning the surface

- Apply benco B-17 or Prematex/Miles stripper

- Soak time of 15-20 mins

- Use brush or scraper to remove the softened powder

How to Remove Powder Coating from Titanium?

Same like steel, tianium can be chemical stripped,abrasive blasted or heat-based removal also be used.

Step-to-Step Guide:

- Chemical solution dissolve the powder coating which can be cleaned with scraper or brush

- Heating titanium in over or by heat gun to burn the coating and then ashes can be removed easily

- Abrasive media like sand or glass bead blast the coating off the surface.

Powder Coating Removal In Plastic Vs Metal

For metal, chemical stripping, abrasive blasting or thermal stripping can be used and for plastic, plastic media blasting is generally sued to avoid damaging the material.

Conclusion

Powder coating is a surface finish process that protects the surface from corrosion and damage. But sometime it requires removal due to repairing or restoring the original surface. It can be done on metal and plastics but removal from plastic is more critical than from metal because specialized powder is formulated for plastic substrate for durability. For metals, chemical strippers are used that are mostly of solvent-based and caustic-based stripper. After removal, proper adhesion requires cleaned and pre-treated surface to bond with new coating effectively.

But choosing a good surface treatment method will save a lot of effort. If you are still worried about your own processing projects, such as the choice of powder coating for CNC Precision Custom Parts, you can contact the professional team: Tuofa CNC Online Machining to assist you in choosing the most suitable one-stop solution! ——From design to CNC processing to surface treatment, we have 20+ years of experience in this field.

FAQs

How Long Does Powder Coating Removal Take?

It take 15min to 2 hrs to completely remove the coating

Can You Reuse Parts After Powder Coating Removal?

Yes, generally they can be used if the parts condition is suitable and the removal process was gentle.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Does Surface Roughness Increase Surface Area? A Technical Guide

Does Surface Roughness Increase Surface Area? A Technical Guide