MIC 6 Aluminum: Properties, Machinability, and Best Uses

Dec 19,2025

Dec 19,2025

For applications such as vacuum chucks, tooling, or machine bases, materials with exceptional flatness and dimensional stability are required. This article presents a material that offers both flatness and dimensional stability, which makes it able to be used in such important applications. This material is called MIC 6 Aluminum and discussed in depth in this article.

What Is MIC 6 Aluminum?

MIC 6 Aluminum is an alloy of Al. It is a cast Al plate which offers exceptional flatness and high dimensional stability. Its common applications include precision tooling, fixtures, jigs, and machine bases.

Mic 6 Aluminum Explained

MIC 6 is not a name based on chemical composition or heat treatment like 6061-T6 Al. It is simply a trade name used in industries for a cast Al tooling plate.

Chemical Component of Mic 6

The following table briefly describes the role of each alloying element in the chemical composition of MIC 6 Al.

|

Element |

% (Typical) |

Role |

|

Al |

Balance |

Base metal |

|

Si |

11–13% |

Castability, stability, and hardness |

|

Mg |

0.10–0.45% |

Strength, machinability |

|

Fe |

0.50–0.70% |

Strength (slight), lowers ductility |

|

Cu |

≤0.05% |

Minor strength |

|

Mn |

≤0.30% |

Grain control |

|

Zn |

≤0.10% |

Minor strength |

|

Ti |

≤0.15% |

Grain refinement |

|

Others |

≤0.15% total |

Trace control |

MIC 6 Aluminum Properties and Basics

The application of any material is decided by its physical and mechanical properties. A material having good properties is used in real-life applications.

MIC 6 Physical Properties

Thermal conductivity, density, thermal expansion, and melting point are important properties of MIC 6 Al to know before it is employed in any part.

|

Property |

Value (Typical) |

Comments |

|

Thermal Conductivity |

~138 W/m·K |

Good heat dissipation |

|

Density |

~2.66 g/cm³ |

Similar to other Al cast plates |

|

Thermal Expansion |

~23.6 µm/m·°C |

Stable during temperature changes |

|

Melting Point |

~577–649 °C |

Eutectic range due to high Si |

MIC 6 Mechanical Properties

Mechanical properties of MIC 6 Al are elastic modulus, tensile strength, and yield strength.

|

Property |

Value (Typical) |

Notes |

|

Elastic Modulus |

~70 GPa |

Standard for Al alloys |

|

Tensile Strength |

~160–170 MPa |

Moderate strength |

|

Yield Strength |

~90–100 MPa |

Stable for the cast plate |

Materials Basic Information

Some of the basic properties of MIC 6 Aluminum are given below:

Flatness Specification

MIC offers excellent flatness, which is often required in applications, such as leakage, wear, and vibrations.

Thickness and Parallelism

- The properties, such as strength, weight, heat transfer, and stiffness, depend on the thickness.

- Parallelism shows how precisely two flat plates are aligned.

Dimensional Stability in Service

Dimensional stability is related to how a metal behaves when the temperatures change. MIC 6 offers exceptional dimensional stability in hot and cold temperatures.

What Is MIC 6 Aluminum Machinability?

MIC 6 Al is quite easy to machine because of its uniformity in the ultra-fine cast structure. These cast plates are heat-treated for easy machining and precision tooling. Its uniformity in the cast structure makes it easier to machine and is often used in the complex-designed products.

How to Machine MIC 6 Aluminum?

For precision machining, mostly CNC machining is used. These are the commonly used processes:

CNC Precision Milling MIC 6

When it is difficult to meet design parameters, CNC milling machining outperforms other processes. The specimen remains stationary while the rotating cutting tools remove the material to get the desired product. For instance, vacuum chuck bases of MIC 6 Al are manufactured using this process.

CNC Precision Turning MIC 6

A CNC turning operation is required for cylindrical-shaped products of MIC 6 Al. In this process, the workpiece rotates while the stationary cutting tools remove the excessive material. The most common products of MIC 6 Al include spacers, bushings, and rings.

MIC6 Machining Challenges

Although MIC 6 Al is very easy to machine, there are still some challenges that occur during its machining:

- Porosity in the cast structure causes pits

- Edge tearing

- Chips clogging

- Low strength for heavy cuts

- Low thickness causes warpage in some sections

- Surface finish variation

Benefits of CNC Machining MIC 6 Aluminum

- CNC machining is an advanced metal fabrication process that provides the following benefits:

- Tight tolerances can be easily achieved in CNC machining, which further leads to dimensional stability.

- Due to mostly automated functions, the chance of human injuries reduces exponentially.

- Chances of errors in the dimensional accuracy are reduced because of mostly automated cutting operations.

- Complex-designed parts can be easily manufactured in CNC machining.

Can MIC 6 Be Welded?

MIC 6 Al shows poor weldability due to its chemical composition. The main reason behind the poor weldability is the high Si content. It causes hot cracking as the weld solidifies. These are the benefits and drawbacks of welding MIC 6 Al:

Benefits

- 4043 filler material ensures stable bonding of two MIC 6 Al cast plates.

- TIG welding is used to fill small defects precisely.

Drawbacks

- Risks of hot cracking during the solidification are high due to high Si content

- Entrapped gases cause severe porosity on the surface

- Heat-affected zone induces weakness in the structure

- Not reliable for load-bearing applications

MIC 6 vs 6061 vs ATP-5

MIC 6, 6061, and ATP-5 are often compared due to their use in manufacturing machining fixtures, jigs, machine bases, and precision machining.

|

Alloy |

Type |

Key Reason for Comparison |

Typical Use |

|

MIC-6 |

Cast tooling plate |

Best flatness and dimensional stability |

Fixtures, molds, jigs |

|

6061 |

Wrought alloy |

Higher strength, lower cost, widely available |

Structural and machined parts |

|

ATP-5 |

Cast tooling plate |

MIC-6 alternative with similar stability |

Tooling plates, bases |

Basic Properties Differences

The basic difference of strength, flatness, machinability, and costs are discussed below:

What Is The Biggest Difference?

- Strength is the biggest difference among these alloys. APT-5 and MIC 6 Al but have lower strength, but offer stable machining.

- 6061 is used in structural applications due to its relatively high strength.

Who Is Flattest as Supplied?

- MIC 6 Al offers the highest level of flatness, followed by the APT-5 grade alloy of Al.

- Due to the wrought structure, 6061 has relatively poor flatness after machining processes are applied.

Which Machines Faster?

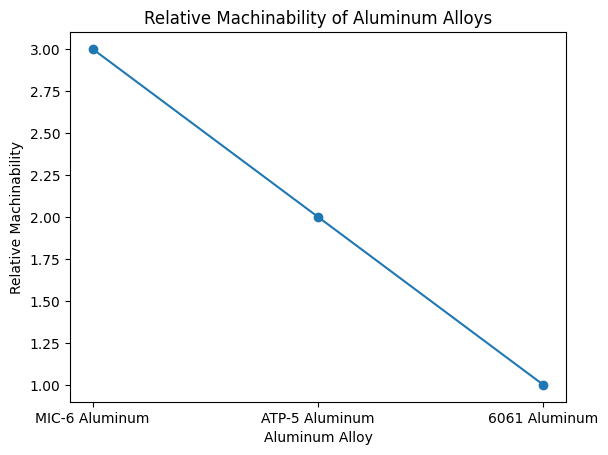

The relativity of the machinability of these grades is shown in the following graph.

It shows MIC 6 Al is easiest to machine while 6061 Al is relatively hardest.

Which Is Cheapest?

6061 Al is the cheapest grade due to its wrought structure and production in high volumes. The costs of MIC 6 Al and APT-5 are slightly higher due to flatness and stress-relief heat treatment.

Cheaper Equivalent to Mic 6

Considering properties and machinability, APT-5 is closest to MIC 6 Al, because both are cast alloys.

Design Rules for Machining MIC 6 Parts

The design of the MIC 6 Al parts is directly related to the machining. A poor design or having unnecessary tolerances can increase the overall machining price and cause tool wear. That’s why designers should consider the following parameters while designing a part of the MIC 6 Al material.

1. Manufacturing Feasibility

- Add coarse threads instead of fine ones, because MIC 6 Al is a cast structure and more brittle compared to wrought alloys.

- Add steel thread inserts for frequently used holes

- For deep holes, use peck drilling

2. Dimensional Stability

- Due to the stress-relieved structure, dimensional stability is higher in larger parts

- A factory flat surface can often be used as-is, avoiding extra machining

3. Specific Tolerances

Designers should avoid mirror-level cosmetic finishes, although it has a good surface finish and tight tolerance. The reason is its cast structure. The entrapped gases may cause porosity in the case of low thickness. The flatness can be reduced by 0.005" without extra grinding or stress relieving. It is better not go tighter than this variation.

4. Material Properties

A design of the part should be made based on its machining stability, not its strength. Because it is very low compared to 6061. It tends to crack instead of bend under heavy loads. Due to high Si content, after machining, the color of MIC 6 Al gets darker or gray.

What Can You Choose for Surface Finishes on MIC 6?

A poor surface finish can lead to fatigue failures. This is why some of the following surface treatments are performed.

Anodizing Mic 6 Aluminum

This electrochemical process increases corrosion and wear resistance, provides decorative appearance, and provides electrical insulation. Anodizing provides an oxide layer to the surface.

Paint and Powder Coat on Mic 6

- For increased corrosion resistance and a decorative look, paint is applied on the surface of MIC 6 Al. For painting, it is important to prepare the surface by degassing, etching, and priming.

- Powder coating is a thick coating that provides toughness and durability to the surface of MIC 6 Al.

Precision Surface Preparation

The purpose of precision machining is to achieve a very fine mirror-like surface finish. This is achieved by using processes, such as grinding and polishing. It is important when parts need a tight tolerance.

Custom Solution in TUOFA CNC Machining

TUOFA is a Chinese company that specializes in precision machining, irrespective of the material. For one-stop solutions, where the process from consultation to providing final products is offered at cost-effective prices and in due time, visit TUOFA. We are equipped with advanced machines and expert labour, so we offer the best machining services for projects regardless of the volume.

Mic 6 Aluminum’s Thermal Behavior in Service

It is very important to understand the thermal behaviour of MIC 6 Al. If thermal behaviour is unknown during the application, it causes major failures. MIC 6 Al expands as the temperature rises and contracts as the temperature reduces.

Coefficient of Thermal Expansion

MIC 6 Al has a slightly higher thermal expansion than Al due to Si content. Its value is 23 X 10-6 oC.

Operating Temperature Limits

The operating temperature limits mainly depend on the type of use. If the usage is continuous, then the maximum temperature must not exceed 150 °C. And if the exposure is for a short time, then the maximum temperature should not exceed 200 °C.

Vibration Damping

Since MIC 6 Al is a stiff cast tooling plate, it cannot be used where vibration damping is required. It has a lower vibration-damping capability, it transmits the vibrations.

Applications & Parts of Mic 6 Aluminum

MIC 6 Al, which is a tooling cast plate, is used in various applications due to its machining and dimensional stability and flatness.

Best Uses in Various Industries

MIC 6 Al material has made its space in almost every industry. The major industries include:

- Aerospace

- Automative

- Electronics

- Packaging

- Consumer Products

- Industrial Machinery

Fixtures and Jigs

MIC 6 Al is used in the aerospace and automotive industries to manufacture fixtures and jigs. These are the reasons behind the wide usage of MIC 6 Al for these parts:

- Lightweight

- Good thermal conductivity

- High machinability

- Dimensional stability

Machine Bases and Plates

Due to:

- Flatness as supplied,

- Lightweight

- High-dimensional stability

- Good wear and thermal resistance

MIC 6 Al is used in the manufacturing of machine bases and plates.

CMM and Optical Tables

Due to lower thermal distortion, sufficient stiffness, and high flatness and dimensional stability, MIC 6 Al is employed in coordinate measuring machines and optical tables.

Vacuum Chucks and Tooling

- It is used in vacuum chucks and tooling due to as-cast flatness and dimensional stability.

- MIC 6 Al creates a perfect surface that maintains vacuum pressure.

Conclusion

MIC 6 Aluminum is a cast aluminum tooling plate, mainly used for vacuum chucks, precision tooling, and machine bases. Its main properties are excellent flatness and dimensional stability. It offers lower strength compared to 6061 Al, so does not used in structural applications. The designers must consider factors, such as machining feasibility, while making a design of the part of MIC 6 Al. The surface of this alloy can be improved using surface treatments, such as anodizing.

FAQs

Is MIC 6 the same as 6061?

MIC 6 Al is a cast tool plate, while 6061 Al is a wrought alloy. So, both are different alloys.

How much is 1 lb of aluminum worth?

According to the trading economics, the price for one pound of Al is 3.1$/lb.

When should I choose MIC 6 over 6061?

Use MIC 6 Al instead of 6061 Al when the dimensional stability and easy machining of the part are required.

What is the aluminum equivalent to MIC6?

In terms of machinability and other properties, ATP-5 Al is very close to MIC 6 Al.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

6063-T5 Aluminum: Temper, Properties, Weld & Machining

6063-T5 Aluminum: Temper, Properties, Weld & Machining