CuZn38Pb2 Brass: Composition, Properties, Machining

Dec 11,2025

Dec 11,2025

CuZn38Pb2 is a well-known brass alloy for its high machinability. This is one of the versatile copper and brass grades that has a unique balance of strength and durability. CuZn38Pb2 is highly valuable in precision engineering and manufacturing for its high corrosion resistance and machining qualities.

CuZn38Pb2 Brass Basics

CuZn38Pb2 is a common leaded brass alloy, which is also called CW608N. The alloy has remarkable cold/hot formability along with high strength and machinability. This unique combination of properties makes it perfect for precision parts like fittings or watch parts.

What Is CuZn38Pb2?

CW608N primarily contains 60-63% copper with a balance of zinc and lead. CuZn38Pb2 brass has good cold and hot working properties like bending, upsetting, and stamping. This copper and brass grade has good corrosion resistance against neutral/alkaline compounds. However, it is prone to stress corrosion cracking (SSC) with ammonia or acids.

What Is the Chemical Composition of CuZn38Pb2?

As for its chemical composition, CuZn38Pb2 is a leaded brass alloy designed for easy-to-machine and high formability. It has a two-phase structure, alpha and beta, that contributes to its combined properties.

CuZn38Pb2 Chemical Composition Range

The chemical composition of CuZn38Pb2 is:

|

Elements |

Percentage |

|

Copper |

60.0 - 63.0% |

|

Zinc |

35-38% |

|

Lead |

1.6 - 2.5% |

|

Iron |

0.2% max |

|

Nickel |

0.3% Max |

|

Tin |

0.2% Max |

|

Aluminum |

0.05%Max |

|

Other |

0.2%Max |

Role of Lead in CuZn38Pb2

Lead is finely dispersed in all over the microstructure which refines the grain structure. This lead also acts as chip breaker and internal lubricants which prevent long and stringy chips. This chip-breaking feature increases cutting speed, reduces friction and overall improves its free-cutting nature.

CuZn38Pb2 Mechanical and Physical Properties

As mentioned above, the excellent machinability of CuZn38Pb2 makes it ideal for high-precision parts. Other brass properties are also present in this alloy like conduction and corrosion resistance which increase its demands in different industries.

CuZn38Pb2 Mechanical Properties

CuZn38Pb2 is a free-machining brass and has high cold/hot working properties. Other mechanical properties are as:

|

Mechanical properties |

Values |

|

Tensile Strength |

400-550 MPa |

|

Yield Strength |

150-250MPa |

|

Modulus of elasticity |

~102 GPa |

|

Elongation |

15-25% |

|

Hardness (HB) |

75-120HB |

CuZn38Pb2 Physical Properties

CuZn38Pb2 has copper-yellow color. other key physical properties are:

|

Physical properties |

Values |

|

Density |

8.44 - 8.5 g/cm³ |

|

Melting Point |

885 - 900°C |

|

Thermal conductivity at 20°C |

~110 W/(m·K) |

|

Electrical conductivity at 20°C |

~24% IACS |

|

Thermal capacity at 20°C |

~377 J/(kg·K) |

|

Linear thermal expansion coefficient |

~20-21 x 10⁻⁶/°C |

|

Magnetic properties |

Diamagnetic |

Here is a free PDF link for more detailed information on the material properties and machinability of CuZn38Pb2: CuZn38Pb2 CW608N Common Machining Materials Free Download

CuZn38Pb2 Properties by Temper

The mechanical properties of CuZn38Pb2 vary significantly with temper. It ranges from soft (annealed/M) with high ductility to hard (R-tempers) with higher strength. This increases overall its tensile strength, yield strength, elongation, and hardness. The standard tempers like M (soft), R360, R410, and R500 have defining ranges for hardness (H070, H100, H120) and strength. Physical properties remain same across tempers but decrease with increased strain hardening.

What Is the Material Equivalent of CuZn38Pb2?

The CuZn38Pb2 equivalent material or that can replace CuZn38Pb2 are as:

CuZn38Pb2 and CW608N Designations

CuZn38Pb2 has approximately 38% Zn and 2% lead. While CW608N or material equivalent to CZ120, C3771 are slightly lead free. Both are used for sheet metal and for parts that need good stamping or forming. Engineers prefer CuZn38Pb2 for good machining properties.

CuZn38Pb2 Standards in EN and DIN

CuZn38Pb2 standardized under EN as 12164/12165/12167 and/or DIN EN 12164 for rods. These are known for good machining & hot stamping sue to ~2% lead.

CuZn38Pb2 Material Equivalents

CuZn38Pb2 material equivalent in EN and DIN standards are:

|

Standards |

Materials equivalent |

|

EN/DIN |

EN 12164 (rods), EN 12165 (wire), EN 12167 (profiles) |

|

UNS |

CW608N (EN), C37700 |

CuZn38Pb2 vs. CuZn39Pb3

CuZn38Pb2 (CW608N) has approx. 38% Zn, 2% Pb. It has good balance of machining and cold/hot workability. While CuZn39Pb3 (CW614N) has higher lead (~3%). It is excellent for free-cutting but is less for cold forming than CuZn38Pb2.

CuZn39Pb3 vs. CuZn38

CuZn39Pb3 has higher lead content (~3%). This much lead is good for machinability but is not typically RoHS compliant (exceeding the limit 0.1%). However, CuZn38 has low or no lead (<0.1%), which is considered as green or lead-free alternative. It is suitable for general purpose parts but has different machining properties than leaded brasses.

Common Applications of CuZn38Pb2 Brass

CuZn38Pb2 has many applications in precision parts, automotive and other applications.

CuZn38Pb2 in Automotive Parts

CuZn38Pb2 is used for producing intricate vehicle parts like sensors, fuel system parts, and other fittings, due to its precision and reliability.

Connectors and Fittings

Electrical connectors, terminals, and plumbing fittings like valves, taps, couplings are typically made of CuZn38Pb2. This alloy is used in automotive and general use due to moderate conductivity and water corrosion resistance.

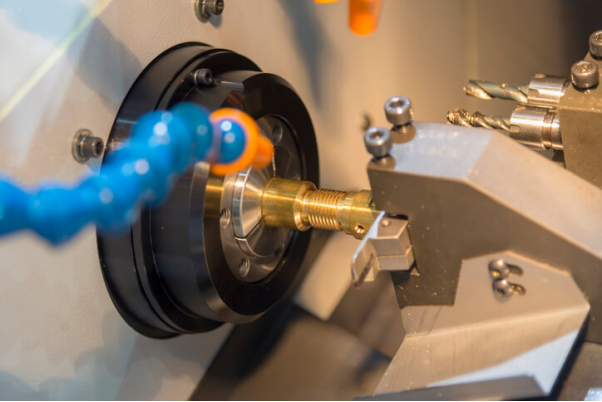

Precision Turned Components

CuZn38Pb2 machines exceptionally well at high speeds. It is used in complex, precise parts for mechanical devices, optics, and instrumentation.

Machining CuZn38Pb2 for Custom Parts

Machining CuZn38Pb2 brass for custom parts is extraordinary due to its lead content, especially CuZn38Pb2 connectors and fittings. Lead helps with fast cutting speed and extends tool life. Precise and intricate shapes in CuZn38Pb2are easy to make in CNC machining.

CuZn38Pb2 Machinability

CuZn38Pb2 has excellent machinability and is great for high-speed machining with carbide and high-speed steel (HSS) tools.

How to Machine CuZn38Pb2

HSS or carbide cutting tools are used for machining brass. Cutting speed is moderate to high and cutting fluids reduces friction. Design tooling and specified cutting parameters (speed or feed) controls chip break effectively.

Precision Turning CuZn38Pb2

Precision turning is for getting tight tolerance and smooth surface finish in CuZn38Pb2. Lead content helps with fast material removal as well as maintaining precision during turning. However, stress relieving is required to prevent SSC in service.

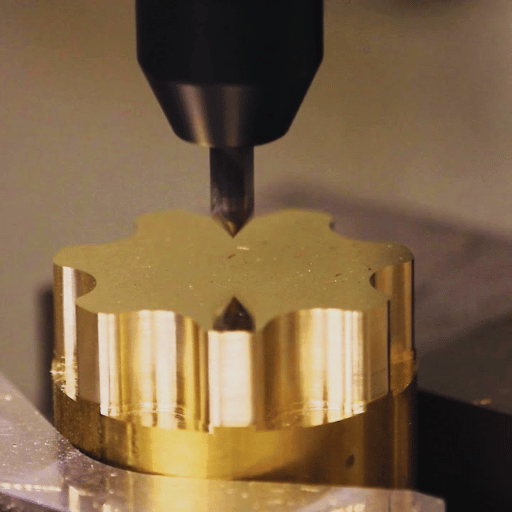

Precision Milling CuZn38Pb2

For precision milling of CuZn3Pb2, sharp and multi-flute carbide end mills are used. Speed and feed rates are according to tool diameter and depth of cut. These parameters are adjusted for consistent sound and chip formation. Fixturing is required to prevent vibration during milling.

TUOFA Custom CNC Machining Brass/Copper Solution

Tuofa offers comprehensive one-stop shop metal part solutions. We offer CNC machining services for metals, plastics, composites and variety of material covering areas like industrial, automotive, robotics, environmental, and electronics industries.

Get a Machinability Check & Free Drawing Review! Quote in 24 Hours

Conclusion

CuZn38Pb2 is a leaded brass alloy and famous for its machinability. It has dispersed lead that act as a lubricant and chip breaker. Good hot and cold forming properties increase its demands for parts like gears, fasteners, and fittings.

FAQs about CuZn38Pb2

Is CuZn38Pb2 suitable for R410 and plumbing applications?

CuZn38Pb2 is not suitable for R410A refrigerant applications, but it is good for general plumbing like faucets or gears.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Nitriding Steel: Importance, Comparison, Applications & CNC Machining

Nitriding Steel: Importance, Comparison, Applications & CNC Machining