Does Metal Expand When Heated? Understanding Thermal Expansion

Jan 09,2026

Jan 09,2026

At times, a conflict might occur between the CNC manufacturer and the client regarding dimensional accuracy. The CNC manufacturer makes parts as per CAD given by the client. But still dimensions deviate from the design. The client wonders: “does metal expand when heated?”. It actually expands! There are many ways to keep this problem at bay. Optimum manufacturing strategies and thermal expansion allowance greatly resolve this issue. Let's discuss this topic in more depth.

What Is Metal Thermal Expansion?

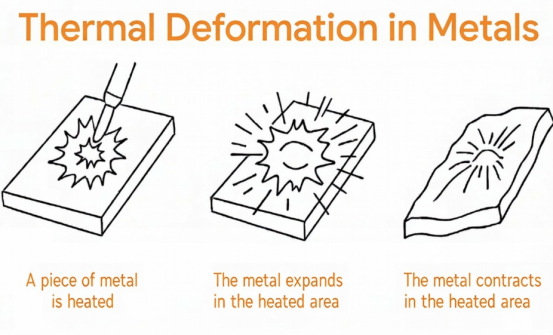

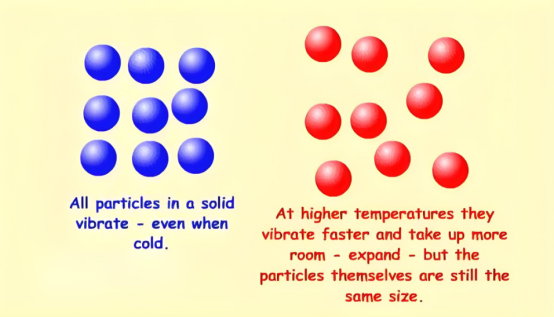

Does metal expand when heated? The answer is yes. It is a phenomenon called Thermal Expansion. Thermal expansion of metals refers to the change in dimensions when temperature rise. Metals are composed of atoms and these atoms are bonded by metallic bonds. As temperature rise atoms gain thermal energy and vibrate more intensely. This causes the atomic spacing to grow. So, metals tend to expand when heated. This metal expansion is critically important in engineering applications. It affects precision, alignment, and structural integrity of components and assemblies.

Does Metal Expand or Contract When Heated?

From the previous section, believe that you have a simple understanding of thermal expansion phenomenon. Actually, metal can only expand when it is heated. Then when the metal contracts? In general, metal contracts and returns to its original size when it cools down.

Why Metal Thermal Expansion Matters?

Metal thermal expansion matters a lot in engineering applications for maintaining functionality and safety of components. It has a dominant role in engineering design, manufacturing, and safety. If thermal expansion of metals remains unaccounted it can lead to thermal stresses, distortion, cracking, or even catastrophic failure. So, engineers include thermal compensation in engineering designs that are subjected to large temperature variations.

Examples of Metal Expansion

|

Application |

Material |

Thermal Expansion Effect |

Precision Impact |

Control Strategy |

|---|---|---|---|---|

|

Optical Lens Mounts |

Aluminum 6061-T6 |

Radial growth with temperature |

Focus shift |

Controlled interference fits |

|

Precision spindles |

Tool Steel |

Axial and radial expansion |

Bearing preload change |

Thermal compensation |

|

Optical Benches |

Invar |

Minimal expansion allowed |

Optical path misalignment |

Stress-relief machining |

|

Mirror and Housing Parts |

Aluminum / Stainless steel |

Localized expansion during cutting |

Surface distortion |

Cooling between passes |

|

Encoder and Sensor housings |

Stainless Steel |

Moderate dimensional change |

Signal accuracy drift |

Tolerance allowance |

|

Gauge and reference Parts |

Tool Steel |

Micron- level length change |

Measurement error |

Climate -controlled machining |

|

Telescope frames |

Aluminum |

Length expansion affects focal distance |

Defocusing |

Expansion joints |

|

Optical Adapters |

Ti-6Al-4V alloy |

Low CTE, heat accumulation |

Temporary size drift |

Reduce cutting speed and high-pressure coolant |

The Effect of Heat on Metal

To answer“does metal expand when heated?”we would need to dive to the atomic level. The added thermal energy influences the vibration behavior of atoms. The more rigorous the vibrations are the more atomic spacing it need. So overall it leads to a volumetric thermal expansion of metals.

Thermal Expansion

Expansion of metals is a direct result temperature rise. As already explained, due to the greater interatomic spacing, metals expand.

Electrical Resistance

Change in electrical resistance is a good indicator of thermal expansion. As metal gets heated, their atoms vibrate vigorously around their lattice positions. It creates a hindrance in the flow of free electrons. As a result, electrical resistance of metals rise.

Structure Changes

As metals are heated certain microstructural changes occur. Above certain temperature levels phase transformations happen. Atoms reorient themselves in a new way. It can modify thermal expansion behavior. So, thermal expansion doesn't always have a linear relationship with temperature.

Magnetism

Ferromagnetic materials like iron, nickel, and cobalt lose their magnetism above curie temperature. It results due to phase transformations and decrease in magnetic ordering.

Advantages of Metal Thermal Expansion

Thermal expansion of metals does not always pose a design challenge. Many a times predictable thermal expansion is taken to our advantage. There are many good applications of this metal expansion behavior. Some of them are discussed below.

Assembly Fit

Thermal expansion of metals can be used for precise assembly fits. A predictable metal thermal expansion is considered in such situations. Assembling is carried out at an elevated temperature. As the metal cools, it shirks back to its original dimensions. So, a tight and reliable interference fit can be attained in this way. This procedure is carried out for tight tolerance parts. Common examples include: shrink fitting of gears on shafts, mounting bearings, and installing metal sleeves.

Thermal Compensation

The thermal expansion of the structure is considered to prevent excessive stress during the design of the parts. Service conditions are analyzed and a thermal compensation is given design features. It makes the parts safe for use in that temperature range.

Functional Applications

- Bimetallic Thermometer

Bimetallic thermometers operate without any external power source. Bimetallic strip with different coefficients of thermal expansion is attached with each other. One metal expands more than the other. It leads to bending. This bimetallic strip is linked to a pointer which indicates temperature.

- Bimetallic Strip Thermostat

A bimetallic mechanism similar to the one explained above is used. Instead of linkage with a pointer, the bimetallic strip is connected with an electrical circuit. As the bimetallic strip bends, it opens or closes an electrical contact. With this opening and closing of electrical contact temperature is controlled automatically.

What Is Coefficient of Thermal Expansion?

Coefficient of thermal expansion(CTE) represents a fractional change in length per unit temperature change. It is an indication of how much a metal would expand or contract for a given change in temperature. A metal with a high coefficient of thermal expansion(CTE) expands or contract more with a change in temperature.

How to Calculate CTE of Metal?

Coefficient of thermal expansion(CTE) represents the metal expansion behavior. Knowledge of CTE makes thermal expansion predictable for designers. There are certain methods to measure CTE accurately for metals and alloys. Let's discuss them!

Dilatometry

A dilatometer measures dimensional changes with changes in temperature. A specimen is heated at a controlled rate. The expansion in dimension is then measured mechanically or electronically. The advantage of dilatometer is that it measures thermal expansion of metals wide temperature range. It is suitable for industrial alloys and bulk metals.

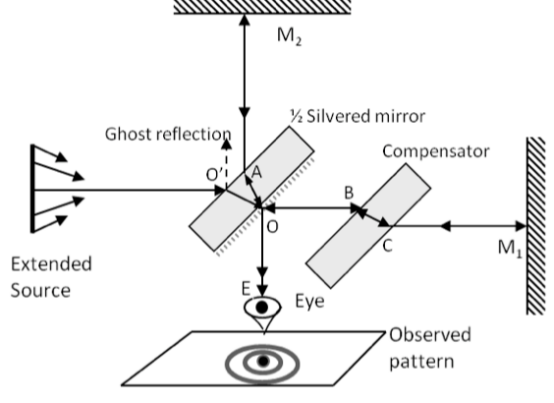

Optical Interferometry

Optical interferometry offers a very high precision. It relies on light wave interference. As the dimensions of the sample changes, it hinders the path of light in a different way. Consequently, interference of light gets affected. Optical interferometry is suitable for low-expansion materials in which expansion is difficult to detect.

Thermal Expansion of Common Metals

Thermal expansion of metals must be considered in engineering applications. Luckily, the coefficient of thermal expansion (CTE) of common metal grades is listed in scientific literature. Coefficient of thermal expansion (CTE) of common metallic alloys is given below:

Ferrous Metals

|

Material |

Equivalent grades |

Typical CTE (×10⁻⁶ /°C) |

Properties |

Applications |

|---|---|---|---|---|

|

AISI 1018 |

ASTM A108 |

11.5- 12.0 |

High ductility, excellent weldability and good machinability |

Structural parts, shafts, plates, general fabrication |

|

AISI 1045 |

ASTM A29 |

11.0 -11.7 |

High strength, high hardness and good wear resistance |

Gears, axles, bolts, crankshafts |

|

DIN 41Cr4 |

EN 1.7035 |

10.5-11.5 |

Good hardenability and high fatigue strength |

Automotive shafts, forgings, heavy machine components |

Stainless steels

|

Material |

Equivalent grades |

Typical CTE (×10⁻⁶ /°C) |

Properties |

Applications |

|---|---|---|---|---|

|

EN 1.4301 |

AISI 304 |

16.0-17.5 |

Excellent corrosion resistance, good formability and non-magnetic |

Food processing equipment, architectural panels, tanks, fasteners |

|

EN 1.4401 |

AISI 316 |

15.5-17.0 |

Superior pitting and chloride resistance |

Chemical processing, marine fittings, heat exchangers, medical devices |

Carbon steels

|

Material |

Equivalent grades |

Typical CTE (×10⁻⁶ /°C) |

Properties |

Applications |

|---|---|---|---|---|

|

AISI 1010 |

ASTM A29 |

11.5-12.0 |

Very good ductility, excellent weldability but low strength |

Deep-drawn parts, sheet metal, pipes, general fabrication |

|

AISI 1018 |

ASTM A108 |

11.5-12.0 |

Good machinability, balanced strength and ductility |

Shafts, plates, structural components, machined parts |

Non-Ferrous Metals

Aluminum and aluminum alloys

|

Material |

Alloying elements |

Aluminum coefficient of thermal expansion (×10⁻⁶ /°C) |

Properties |

Applications |

|---|---|---|---|---|

|

Al-Mg-Si alloy |

23.0-23.6 |

Good strength, excellent machinability and good corrosion resistance |

Structural frames, heat sinks, automotive and aerospace parts |

|

|

7075-T6 |

Al-Zn-Mg-Cu alloy |

23.0-23.5 |

Very high strength but lower corrosion resistance than 6061 |

Aircraft structures, high-stress components, molds |

|

5052 |

Al-Mg alloy |

23.5-24.0 |

Excellent corrosion resistance, high fatigue strength and good formability |

Sheet metal, marine components, enclosures |

Copper and Copper alloys

|

Material |

UNS Designation |

Coeffcient of expansion of Copper alloys (×10⁻⁶ /°C) |

Properties |

Applications |

|---|---|---|---|---|

|

C11000 |

Electrolytic Tough Pitch (ETP) Copper |

16.5-17.0 |

Excellent electrical and thermal conductivity |

Electrical conductors, busbars, heat exchangers |

|

C36000 |

Free-Cutting Brass (Cu-Zn-Pb) |

18.5-19.5 |

Excellent machinability but moderate strength |

Valves, fittings, precision machined components |

Titanium Alloys

Does titanium expand with heat? Yes it does, but its expands less than other common metals. Here is the CTE of Titanium alloys Ti-6Al-4V.

|

Material |

Alloying elements |

CTE (×10⁻⁶ /°C) |

Properties |

Applications |

|---|---|---|---|---|

|

Ti-6Al-4V |

Titanium- Aluminum- Vanadium |

8.5-9.0 |

High strength-to-weight ratio, excellent corrosion resistance and good fatigue resistance |

Aerospace components, medical implants, high-performance automotive parts |

High-Temperature Alloys

Different from above metals, some typical materials have superior high-temperature deformation resistance such as Tungsten.

Tungsten

Tungsten is a thermally stable material to an extent that people ask: “Is tungsten the most heat resistant metal, heating tungsten?”. Its CTE is even lower than that of Titanium. Lets see its data:

|

Material |

Alloying elements |

CTE (×10⁻⁶ /°C) |

Properties |

Applications |

|---|---|---|---|---|

|

Tungsten |

Commercially Pure |

4.5-4.8 |

Extremely high melting point, very high density, excellent wear and corrosion resistance |

Filaments, high-temperature heating elements, aerospace components, radiation shielding |

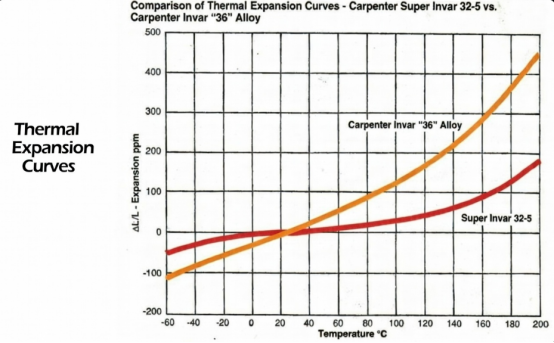

Low-Expansion Alloys

Low-expansion alloys has extremely low coefficient of thermal expansion (CTE), which means that they hardly deform when heated. This outstanding dimensional stability makes these alloys used in some vital applications that have high requirements for dimensions and accuracy. Invar is a well-known example.

Invar

The CTE of Invar metal is the lowest of all metals and alloys. Due to its dimensional stability, it is used in precision instruments.

|

Material |

Alloying elements |

Invar thermal expansion cofficient (×10⁻⁶ /°C) |

Properties |

Applications |

|---|---|---|---|---|

|

Invar |

Fe-Ni Alloy |

1.0-1.2 |

Extremely low thermal expansion, good dimensional stability but moderate strength |

Precision instruments, clocks, measuring devices, aerospace components, scientific equipment |

Can Heat Treatment Affect Metal Expansion?

Yes, heat treatment has a minor effect on metal expansion behavior. It typically does not significantly alter the inherent CTE. But, slight changes occur due to changes in microstructure, carbon absorption or relieving of residual stresses.

Microstructural Changes

Microstructural changes at certain temperature levels affect the metal expansion bit. As an example, when steel is heated above 7270C, its ferrite/pearlite phase starts to transform into austenite phase. Ferrite has BCC lattice structure with an atomic packing factor of 0.68. While austenite has a FCC structure with an APF of of 0.74. As a matter of fact, APF of 0.74 is denser than an APF of 0.68. So, an shrinkage might be expected at 7270C for steel.

Carbon Absorption

Carbon is absorbed in heat treatment processes like carburizing. As carbon gets absorbed, the surface layer tends to expand.

Relieve Residual Stress

Residual stresses impart non uniform expansion behavior in metals. During heat treatment processes like annealing, residual stresses get relieved. So, the metal becomes free of stress and consequently, it becomes more isotropic.

Does Metal Expand When CNC Machining?

Metals do expand During CNC machining. Friction between cutting tools and workpieces generates significant heat, resulting in temperature increases for the workpieces, cutting tools, and machine tool components. This temperature increase might expand the metal workpiece or tool.

Workpiece Expansion

As friction causes the workpiece to heat up, expansion is expected. This heat causes an expansion near the tooling surface. So, the dimensions during machining deviate from the finally cooled parts. This effect is specifically noticeable in thin-walled or long parts.

Tool Expansion

Temperature increase has a noticeable effect on dimensions of tools. As the tip diameter and length expands, it can lead to dimensional inaccuracies. Some features can be overcut and there can be a gradual dimensional drift. To address this problem, proper coolant flow and thermal compensation in cutting must be included.

Metal Expansion Effect on Machined Metal Parts

Thermal expansion is a factor that must be considered in metal machining, which directly affects the dimensional accuracy, the deformation of parts and the machining quality. This volumetric expansion of metals affects more in high-speed machining, tight tolerance parts, and materials with high CTE.

Dimensional Changes

The machining surface of the workpiece might become hot due to friction. It causes metal expansion during machining. As the part cools down, it shrinks a bit. This makes dimensions to deviate from the intended dimensions.

Local Deformation of Parts

The portion of the parts that are subjected to machining get a local rise in temperature. Other areas remain at low temperature. This temperature inequality leads to local deformation phenomenon like warping, bending, or twisting of the part. This thin-walled components, pockets, and ribs are particularly susceptible.

Precision and Fit Impacts

Thermally expanded parts make their dimensions out of tolerance. It is especially important for holes, slots, and mating surfaces where parts proper fitting relies on accurate dimensions.

How to Minimize Influence of Metal Expansion?

Accuracy, performance, and security of parts are influenced by temperature. To keep consistent quality of parts, minimize the effect of metal expansion is important.

Use Low-Expansion Materials

For tight tolerance part that require a high precision, use of low CTE materials is essential. Considering the cost factor and the dimensional accuracy needs, Invar, Ti6Al4V alloy and Tungsten are good choices.

Constant Environmental Temperature

Ideally the machining temperature should be as close as final use temperature. The machining environment temperature also matters a lot for critical parts. ISO standards give an ambient temperature of 20 0 C for working environments. Maintaining a constant temperature will give identical dimensions for all the parts.

Optimize Machining Strategy

Prevention of excessive friction and unnecessary heat is root of all good machining strategies. Use of proper coolants and lubricants are conducive in this respect. High feed rate and shallow depths also avoid unnecessary heat built up. Non metallic tools like CBN or carbide tool are less affected by thermal expansion. In modern CNC systems, thermal probes automatically adjust the dimensional drift.

Allowance for Thermal Expansion

Reasonable thermal expansion allowance must be given for metal parts. As an example, Aluminum parts with length of 500mm with a CTE of 23 x 10-6 machined at 30 0 C, but used at 20 0 C will show an shrinkage off 0.11mm. Now, if tolerance allowance is only + 0.05mm, the part will fail. A fluctuation of 10 0 C is quite normal. So, a reasonable thermal expansion allowance for metal parts should be given. With decades of machining experience, Tuofa machines precision parts with advanced techniques and strict quality inspection.

Conclusion

Thermal expansion of metal is many a times an unavoidable phenomenon. In high precision parts thermal expansion deviate dimensions far away from the actual design. The use of optimum machining strategies and consideration of CTE and temperature variations leads to manufacturing of high precision parts used in critical applications.

FAQ

Does plastic expand in heat?

Yes, plastics also expands by heat. But, this phenomenon is not as pronounced as in metals.

What expands more, aluminum or steel?

Aluminum has a higher CTE than steel. So, it expands more.

Which metal has highest thermal expansion?

Among common engineering materials, Aluminum and its alloys have amongst the highest thermal expansion among all common metals.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Leaded Brass: A Properties, Grades, and Machining Guide

Leaded Brass: A Properties, Grades, and Machining Guide