What is Cellular Manufacturing? -A Lean Manufacturing Method

Aug 25,2025

Aug 25,2025

Cellular Manufacturing is a manufacturing system that has a combination of production process lined in a single manufacturing cell. In US, there are over 1,000 systems that have over 8,000 employees in the manufacturing layout sector. This system reduces setup times; inventory costs and simplifies the production process. More detail about the different aspects related to cellular manufacturing is in this blog. So, let's get started!

What Is Cellular Manufacturing?

Cellular manufacturing arranges machinery and workstations into "cells" to fabricate a product. It creates a miniature production line in a single cell which increases efficiency and flexibility and gives less waste. This strategy is a key part of lean manufacturing. Lean manufacturing is a system with the focus of eliminating waste, prioritizing customer values, and continuously improving processes. Cellular manufacturing creates products like automotive valve bodies, aerospace brackets, medical instrument handles, electronics heat sinks, and bicycle hubs.

Types of Lean Manufacturing Methods

Lean manufacturing uses different methods to reduce waste and costs, increase efficiency, and increase product quality. These are:

- Just-In-Time (JIT) production.

- Kaizen for continuous improvement.

- 5S for workplace organization.

- Kanban for pull system.

- Poka-Yoke for mistake-proofing.

- Heijunka for production leveling.

- Value Stream Mapping to visualize process flow.

- Jidoka to automate error detection and correction.

How to Define Cellular Manufacturing

It is a lean production strategy that combines machines and equipment into dedicated workstations, called cells, to produce similar products.

One-Piece Flow

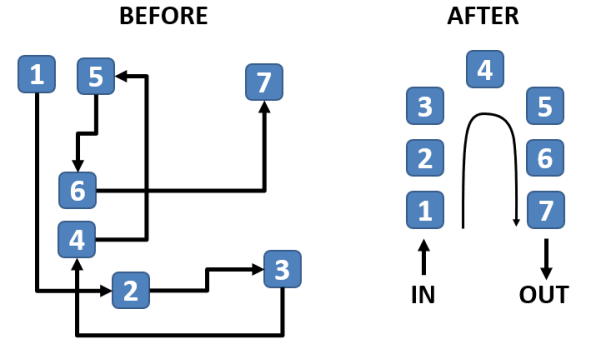

One-piece flow is also called single-piece flow. It is a lean manufacturing method in which only one unit of a product moves through the production line at a time and not in large batches.

Cellular Manufacturing Examples

Some common examples are automotive assembly line, electronic manufacturing and for custom product fabrication.

Cellular Manufacturing vs Traditional Assembly Line

There are several differences between cellular manufacturing and traditional assembly lines and these are as:

Flow and WIP Differences

Traditional production lines produce standardized products. While cellular manufacturing fabricates products with variations. For example, each work cell produces single subassembly used in a product and utilizes families of parts to form variations of the subassemblies.

Flexibility and Product Mix

Cellular manufacturing has higher flexibility for product mix and for smaller batch sizes. Traditional assembly is suitable for high-volume and single-product production. Cellular manufacturing' has quick reconfiguration and can integrate quality control for varying product types. And the traditional assembly layout creates longer material flows with less flexibility for product mix.

Quality and Rework Handling

Cellular manufacturing handles quality and rework more effectively. It combines related machines and multi-skilled workers into cells and does immediate team accountability for defects rather than doing isolated inspections. In traditional assembly, defects are often sent to separate rework stations.

Changeover Time

Cellular manufacturing has shorter changeover times. The cellular manufacturing layouts arrange equipment for a specific product family and have a quicker setup. While traditional assembly often requires extensive machine adjustments and reconfigurations.

Cost Comparing

Cellular manufacturing is more cost-effective because of less material handling, work-in-process (WIP) inventory, setup times, and lead times. While traditional assembly has a process layout with large and single-purpose machines.

When Cellular Manufacturing Works Best

There are several conditions when cellular manufacturing works best:

Repeating Parts Families

Same parts are grouped into families and create an efficient CNC machining work cell for that family. This allows to perform the most important processing steps and reduces travel time and setup.

Overlapping Routings

Single cell can efficiently handle the part's family that has same processing sequence and route in same machine with different orders. This increases flexibility and resource utilization.

Short Takt, Small Lots

Cellular manufacturing is a continuous, one-piece flow of production. This is highly effective for frequent small batches and quick turnaround times and offers faster adjustments to production needs.

Compact Parts

A single cell which groups machines and workers into a small, dedicated unit for smaller parts production is more efficient than traditional manufacturing.

Cellular Manufacturing Layout Types

Cellular manufacture-ng has different types of layouts, and these are:

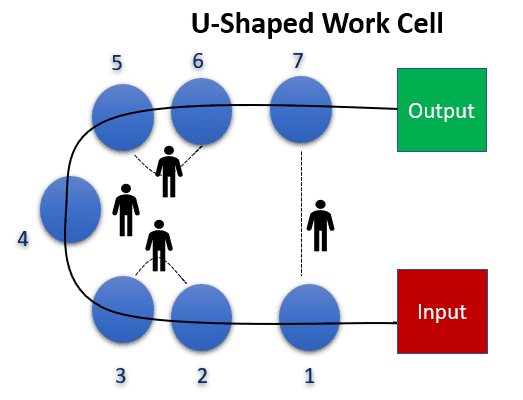

U-Shaped Cell

In this cell machines are organized in U-shape layout and create a compact and space-efficient layout. It is used when product needs high levels of worker communication and collaboration. It arranges technicians closely and that is the most common layout due to space efficiency.

I-/Linear Cell

Mahcines are organized in a straight line in this layout. It is used for products with straightforward, sequential operations to move in a single direction.

O-/Cage Cell

It has a circular arrangement of machines and is used for products that need multiple passes through the same machines. It has a highly skilled technician who operates all machines.

L/T/S/Z Shapes

L-shaped is a simple process sequences and used for simple product. T-shaped is for materials from different sources. S-shaped is to work around obstructions and maintain the production flow. Z-shaped is same as the S-shaped to navigate around obstacles.

Cellular Manufacturing Layout Examples

Some real-world examples of these layouts are:

- U-shaped is used in final assembly of consumer electronics devices

- I-shaped is used for a simple machining process

- Cage cells are used for the products with complex finishing processes

How to Implement Cellular Manufacturing Process

To understand how to implement a cellular manufacturing process, consider these tips.

Group Your Part Families

First, group products into part families based on design, processing or customer needs similarities. Then identify the right machine and tools and arrange them in the work cell.

Coding and Classification Basics

Collect part data and classify and code parts into families using methods like visual inspection or production flow analysis. Develop a part-machine incidence matrix and arrange similar machines into cells.

Choosing Machines and Tools per Family

After arranging similar machines and tools for a similar family, integrate lean principles, train workers, and create a continuous improvement process to optimize the new cell system.

Tips for Better Implementation

For better implementation, consider these tips

- Implement a pull system like Kanban

- Standardize procedures and train personnel within the cells

- monitor performance and make improvements

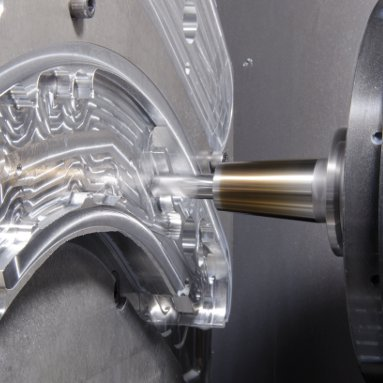

Cellular Manufacturing in CNC Machining

This manufacturing optimizes CNC processes and physically groups the related equipment and resources into dedicated "cells" to produce families of parts. This system has higher productivity, efficiency, quality and flexibility with less material flow, and shorter lead times.

Turning and Mill-Turn Cells

CNC turning and Mill-Turn cells streamline the production of cylindrical parts which need turning and turning/milling operations. They combine lather and mill-turn machine into a single cell and provide a cohesive, one-piece flow. They produce parts like shafts or rings for automotive or aerospace applications.

Milling/5-Axis Cells

Milling 3/5-axis cells optimize the machining of complex, multi-axis and prismatic parts. They organize 3-axis and 5-axis machines to create intricate and complex geometries within a single flow. For example, electronics like heat-sink housings or drones parts.

Hard-Metal Machining Cells (titanium, stainless)

These cells can machine difficult-to-machine materials like titanium or stainless steel. The CNC equipment and tooling are grouped effectively and efficiently to create hard metals parts. Examples are aerospace and medical devices parts.

Advantages and Disadvantages of Cellular Manufacturing

There are a number of advantages to Cellular Manufacturing but also have some limitations.

Key Advantages of Cellular Manufacturing

Cellular manufacturing offers:

- less material handling time and reduces lead time.

- better quality control and faster defect identification.

- higher productivity, and better work-in-progress (WIP) inventory management boost output.

- Less waste production.

- Better worker morale with higher job satisfaction and motivation.

- Better communication and flexibility.

- Cost-effectiveness and less set-up times.

Key Disadvantages of Cellular Manufacturing

The limitations of cellular manufacturing are:

- Higher initial capital investment:

- High risk of delays and disruptions:

- Challenging to balance workload.

- Higher process complexity overall.

- High potential loss of flexibility.

Risk Controls of Cellular Manufacturing

Risk controls are supply chain management for raw material availability, cybersecurity measures to prevent disruptions from cyber threats, complex safety protocols for workers, and flexible design to adapt demand changing and reduce the risk of delays.

How Does Cellular Production Reduce Waste?

It reduces waste by organizing machinery into work cells for product families. It streamlines the process and minimizes material handling, transportation, waiting times, and inventory. A continuous flow improves communication and reduces defects through immediate quality control within the cell.

Conclusion

Cellular manufacturing is a lean manufacturing approach. It arranges the workstations and equipment into small, dedicated cells and fabricates a limited range of similar products. All the necessary machines are placed together and team members worked in a U-shaped layout with these machines. This manufacturing reduces material movement, waste, and creates a smooth, continuous "one-piece flow”. It increases production speed and flexibility overall.

Streamline Your Production with Cellular Manufacturing. Call TUOFA today, a one-stop-solution for all your needs!

FAQs

What is an example of cellular production?

The most common example for cellular production is a company like Dell arranging its computer factory into multiple cells.

What is the difference between cellular manufacturing and flexible manufacturing?

Cellular production arranges machines into cells. While flexible manufacturing is an automated system for a broader range of products and quantities.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Drone Manufacturing: Types, Parts & CNC Custom Solutions

Drone Manufacturing: Types, Parts & CNC Custom Solutions