How to Get Custom Guitar Picks? -Step by Step Design & Machining Guide

Sep 26,2025

Sep 26,2025

A fun and creative way to personalize your music experience is by designing your guitar picks. This blog will guide you how to choose material. CNC machining process and most importantly an experienced service provider for the project of your custom guitar picks.

When Will You Need to Make Custom Guitar Picks?

Custom guitar picks can enhance your music experience by tone customization. It offers unique designs and ergonomics (functional designs), high durability for your guitar picks (made of metal or carbon fiber), better grip and surface texture and personalization and branding with your signature, logo or custom artwork.

What Are Custom Guitar Picks?

These are personalized picks that are designed with unique materials, shapes, and thicknesses and branding with printed logos, artwork, or text. Custom picks provide a better way to modify the look and feel of the pick to suit a player's individual style, playing technique, or marketing needs.

Custom vs. Standard Guitar Picks

Standard picks are purchased with pre-existing designs, colors and materials. While custom picks are personalized with a player’s artwork, brand logo and photo. They also have a unique grip, texture and features unlike standard guitar picks that are mass-produced.

Do Picks Affect Guitar Tone?

Yes, guitar pick has a noticeable change in tone of a guitar. A player can change to alter their sound in the sound chain. The level of effect depends on the type of guitar like electric or acoustic. Acoustic guitars have more dramatic tonal differences.

Who Uses Custom Picks

Custom picks are used by professional musicians, bands, and businesses for promotional and branding. Some well-known musicians are:

- Eddie Van Halen:has a custom Dunlop Max-Grip picks with his name.

- Scott Ian (of Anthrax):has custom picks from D'Addario.

- James Hetfield (of Metallica)has custom artist models with Dunlop.

Guitar Picks Manufacturing Methods

Guitar picks are normally made by Precision CNC machining or laser cutting.

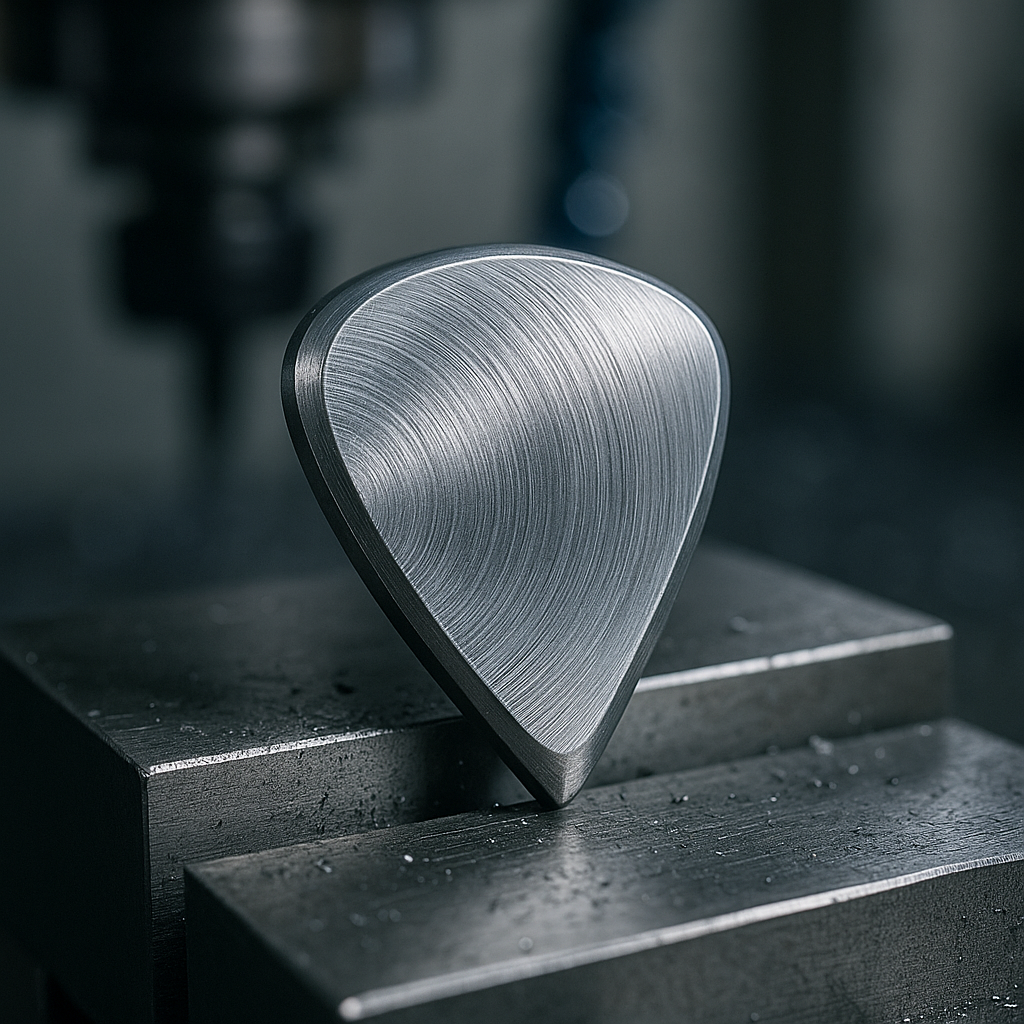

CNC Machining Precision Custom

Computer Numerical Control (CNC) uses computer automation to precisely cut and shape picks from materials. It is best for intricate designs, prototyping and for custom batches.

Other Methods

Puch cutters, injection molding and die casting are also used to make custom guitar picks.

Benefits of Choosing CNC Machining Custom Guitar Picks

CNC machining improves performance, tone, and comfort of a guitarist. It also offers customized physical and tonal attributes that cannot be done with bulk custom guitar picks.

Precision Geometry

CNC machining has programmed software which forms highly accurate, uniform, and repeatable cuts. It can also create picks with consistent thickness and gauge. Thick picks have better control and a full-bodied tone. It also has high dimensional accuracy and can have tight tolerances up to 0.004 mm. This offers a flawless consistent shape and fit.

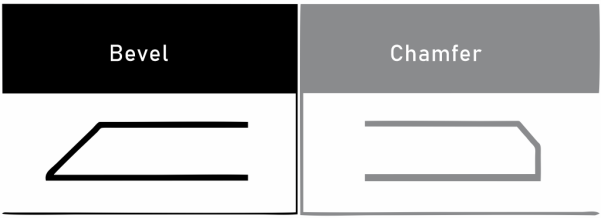

Custom Bevel Profiles

Beveled and chamfered edges on guitar picks improves its attack, tone and speed. CNC Machining creates custom bevels with extreme precision and reduces fatigue.

Material Versatility

CNC machining can work with a wide range of materials and offers greater freedom of design and material selection. The expanded material option from plastic to metal, wood, bone and composite offers high level of durability and tonal quality of pick. Complex designs and personalized aesthetics are also possible with CNC machining unlike other methods.

Premium Edge Finish

High-quality finishing on a pick is important for both comfort and sound. CNC machines create smooth and consistent edge finishing Machined guitar picks with better handling and feel, durability and tone consistency.

How to Choose Custom Pick Materials?

Custom guitar picks have bright, clear attack and unique feel. The type of material highly affects the sound and playability of Machined guitar picks.

Metals Guitar Picks

Different types of metal used in guitar picks offer different feels, grips, tonal profiles and finishing. Common metal used in guitar picks are:

Stainless Steel

Stainless steel picks have good hardness, bright tone and corrosion resistance. normally stainless 304 and 316 are used in picks. They offer a precise, stiff feel with no flex. Grips depend on the finishing, smooth finish can be slick, and textured surface offers more control. It has a very bright and sharp attack and extra weight contributes to

Titanium (Ti-6Al-4V)

Ti-6Al-4V is used in guitar pick due to its lightweight and high strength-to-weight ratio. It has a crisp, bell-like tone with excellent clarity and definition. Titanium alloy with satin or textured finish can enhance grip.

Aluminum (6061)

Aluminum 6061 has medium-to-high strength but has similar lightweight feel. It offers a very fast feel and more brightness and attack than most plastic picks. Anodization provides a durable surface with better grip

Nickel Silver/Copper

Nickel silver picks have a similar rigidity to stainless steel but a surface with smooth or textured polished enhances grip. It has a clear tone with good high-end response and provides a defined, expressive sound under gain. While Copper and its alloys tarnish quickly and have a naturally tacky, grippy surface. It has low impact noise against the strings that create a less aggressive sound than steel or titanium.

Engineering Plastics Guitar Picks

There are a few commonly used engineering plastics for guitar picks. Their details are:

Ultem (PEI) Picks

It is a preferred engineering plastic among musicians for guitar picks because of its bright, articulate tone and durability. CNC polishing on Ultem picks is a common manufacturing technique which refines the surface finish of Ultem. It further improves performance and feel.

PEEK Guitar Picks

PEEK (Polyetheretherketone) is a high-performance thermoplastic polymer. PEEK picks have high speed and precision and less irritating pick noise which makes a unique tonal quality and is valuable for live performance and studio recording.

Polycarbonate (PC) Picks

PC is CNC friendly for making guitar picks. The material’s properties are best suited for this use, and its high impact resistance and good machinability make CNC milling easy.

Delrin / Acetal / Tortex

Derlin/ Acetal and Tortex picks are similar and have unique texture picks. Tortex picks have a matte surface and deliver a bright and crisp tone with a snappy attack. Delrin picks have a smoother surface and have slightly dull or thick sound.

Nylon Guitar Picks

Nylon picks have softer feel and a darker tone. They cannot break easily as celluloid does and have an easier grip.

Other Common Pick Materials

Other than these there are other types of picks like bones, wood, stone and glass, horn, coconut shell and felt. They all have unique tone and grip depending on the hardness, density and durability of material.

Core Factors Affecting Your Guitar Picks

There are different factors that affect the tone, articulation and playability of guitar picks like pick’s shape, size and playability.

Common Guitar Picks Shapes

Some common shapes of guitar picks are as:

Standard 351

This is a classic and versatile tear-drop shape. It is an all-purpose design that works well for a wide range of playing styles.

Jazz III

It is smaller than standard design. Jazz III has a sharper and more pointed tip. This design has greater precision and speed.

Triangle/Teardrop

Triangle shape has three same playing tips which have high durability, and a large surface area for a comfortable grip. Teardrops are a variant of standard shape and have smaller profiles and tapered tips for a softer attack.

Thickness Gauge (0.38–3.0 mm)

The thickness or gauge of pick dramatically affects its flexibility and the resulting tone. Thin picks are 0.38–0.60 mm and medium picks are 0.6-0.6mm and heavy picks are >0.8mm.

Custom Shapes and Thickness

Custom picks are extra heavy of >1.2mm and preferred by jazz players. Custom shapes include round and sharpen the tip.

How Custom Picks Are Made

There are normally three methods to make guitar picks which are CNC-machining, laser cutting and injection molding.

CNC-Machined Picks

CNC machining produces highly précised carved picks from solid blocks or metal sheets. It is best for thicker and harder parts and for creating 3D complex features. CNC-machined picks have higher precision and consistency and high-quality finish. it can create from broader variety of material like metal, plastics, wood or composites

Laser-Cut Picks

Laser cutting used high-powered laser to cut 2D shapes. It is a faster and cleaner method and best for flat and thinner picks. It is ideal for hard material that needs 2D cuts and for decorative purposes. Small batches and prototypes are best suited for laser cutting methods.

Injection/Stamp-Cut Picks

These are one of the common methods for mass-producing CNC guitar picks. Molten plastic injected into a custom-made mold and the stamping uses a die to punch shapes out of a sheet of material

CAD/SVG Templates for CNC/Laser

The type of design file is based on manufacturing process and complexity of the pick. CAD file is best for machining because it has more precise geometric data. SVG file is best for creating 2D vector graphics for laser cutting.

Edge and Finishes of Custom Guitar Picks

Edge and finishing of a guitar pick are important because it directly affects tone, speed, and playability. Different edges and finishes produce a range of sounds and feel in custom guitar picks CNC.

Speed Bevel

It is a diagonal and asymmetrical cut on the edge of a thicker pick. Speed bevel is designed for players who angle their pick when playing and best for fast alternate picking, sweep picking, and lead guitarists.

Rounded Edge

These picks have rounded or smooth edges which are less aggressive and have a softer attack. These are best for rhythm guitarists, acoustic playing, or for smoother tone with less attack

Polished Mirror

Polishing creates a mirror finish with a reflective shine. These guitar picks have brighter, slicker and more defined tone compared to matte or rough finish.

Matte Micro-Bevel

This finish has speed and control of a beveled edge with a non-glossy and unpolished surface. It has unique balance of speed and attack in custom guitar picks CNC

How to Make Grip for Better Control

A controlled grip can be obtained by adding a textured surface, creating hole patterns, or trying a custom design with raised features. Different methods combined with different tools and applications give a desired result.

Raised Logo Grip

Brands such as Rombo and Dunlop manufacture picks with raised logo and 3D geometries for high frictional grip. But some guitarists find these aggressive textures uncomfortable for long playing sessions.

Hole Pattern Grip

It is a modification to a pick to improve grip, especially for players with sweaty hands. A hand drill can create small bits around 2mm or a custom hole for thinner picks.

Sandblast/Etch Texture

Sandblasting machine creates deep and textural valleys in the guitar wood or at pick’s surface. This finish creates a strong grip but can be aggressive.

Ask for Expert Advice

If you're not sure about which method to choose, consider asking an experienced luthier or guitar technician or CNC-machining expert like TUOFA. They can help you with a suitable technique or a different pick style to solve your issue.

How to Plan Your Custom Guitar Picks Projects?

Most of the guitarist are confused or have a question how to make guitar picks? A simple answer is CNC guitar picks are best suited for most of the playing styles, tone targets and feel.

Define Design Purposes

The feel, tone, and performance of your pick are all affected by the material, shape, and thickness. The first thing is to define your playing style and tone goals. materials like Nylon make a balanced sound or Ultem makes a bright and crisp tone and metal makes bright and sharp tone.

Prepare Design Files (SVG/CAD)

Then choose design parameters and create 3D model in CNC machine. SVG files are best for simple 2D shapes, like the pick's outline or surface engravings. CAD files have all 3D geometry and tolerances needed to precisely machine the part. And STEP and IGS are vendor-neutral file types that work across different CAD systems.

Find a One-Stop Machining Shop

Then find a "one-stop shop" like TUOFA which offers end-to-end services, from material selection guidance to production and finishing.

Looking for expert advice, call TUOFA today!

Conclusion

Custom CNC guitar picks can be done by using service to print your designs or by creating your DIY design. The best method depends on the batch quantity like bulk custom guitar picks or a few custom-shaped ones. Using advanced tools like CNC machines, guitar picks can be made easily by yourself or hire a manufacturing service like TUOFA for your best custom guitar picks.

FAQs

How much does it cost to make custom guitar picks?

It depends on the level of customization, material selection and the batch quantity.

What thickness is best for metal riffs?

Most players choose picks in the 1.14 mm to 3.5 mm+ range

How to print guitar picks?

You can print best custom guitar picks by designing your pick in CAD software, slicing it for a 3D printer, and using material like plastic or resin.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

How to Remove a Broken Tap: Something You Must Know

How to Remove a Broken Tap: Something You Must Know