What Is Breaking Strength? Something You Must Know!

Sep 20,2025

Sep 20,2025

When you see ropes in the cranes for lifting very heavy weights like containers. One thing that we think about is that how much load will crane carry easily and also the ropes will not break. This is what is called breaking strength by the engineers. There is a detail below, you will see what is the breaking strength, how to calculate it and why do we give it importance. What should you do and what should you see very closely to avoid dangerous accidents or failures.

What Is Breaking Strength?

Breaking strength is something you can say that when we apply force to a material and it breaks. How much force the material faced before breaking is breaking strength. It is the end limit of that material. It is in Newton (N) or Kilogram Force (Kgf).

How to Define Breaking Strength?

Breaking strength, when we simply put it is when you tie rope at one end and press toward yourself at other end. It breaks the rope in two pieces. Fracture strength or fracture stresses are also the name of breaking strength.

Breaking Load vs Ultimate Strength

Breaking load is the load at the very end point that caused the material to break completely. You can see the breaking load with you own eyes very easily.

As the material has started to break or you can say the point where material has started getting broken. That is Ultimate strength or UTS (ultimate tensile strength).

Ultimate tensile strength and breaking strength usually mean almost the same thing — they both refer to the maximum stress (or force) a material can take before it breaks.

Differences

The biggest difference appears when testing ductile materials (like most metals such as steel or aluminum) in a standard tensile test.

Ultimate tensile strength (UTS) is the highest point on the stress-strain curve — it's the maximum engineering stress the material reaches before necking (when the sample starts to get thinner in one spot).

Breaking strength (or fracture strength) is the stress at the very end, when the material actually snaps into two pieces. Because of necking, this final stress is usually lower than the UTS on the engineering curve.

Where it Appears on Specs Sheets:

It is written in one column of the specs sheets of ropes or wires. You will usually see terms like Breaking load, Ultimate strength or Safe working load indicating the breaking strength.

Breaking Strength Vs Tensile Strength:

People always assume breaking strength and tensile strength as one. But both are different and offer different properties in materials. Let us break both terms and see a detailed version of them.

What is tensile strength?

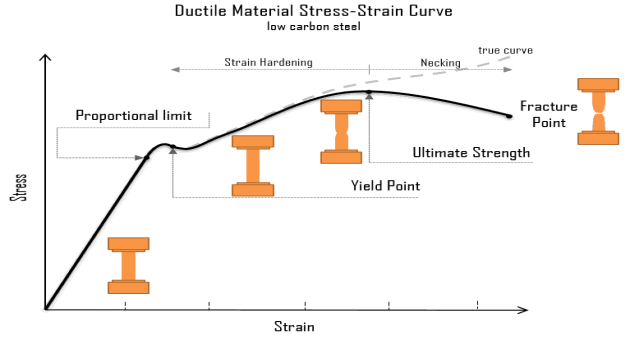

Tensile strength is the highest load a material will face and after this force, material will start to break. Ductile material has a different graph; brittle material has separate. Now you will see terms in graph and they will be explained also:

Fig 1. Stress-strain curve of Low Carbon Steel at room temperature

- Proportional Limit:

As you can see a very straight line at start, this straight line is proportional limit. It is only until where the straight line has started turning. In this material is stretchy and comes back to as it is if force is removed. The shape is not changed in it.

This is the point where the material looks like has started changing the shape. The material doesn't come back as it was before if load is removed.

- Ultimate strength:

This is the maximum load a material can bear when deformed plastically. This is where the necking starts, or you can say the material starts to break.

- Fracture point/Breaking point:

The Fracture point is also the breaking point; it comes when material is broken into two parts like you break a wood stick with your hands.

- Strain Hardening:

What happens in strain hardening is material change its shape when you apply force. It starts from the yield point until Ultimate Tensile Strength. What actually happens is that when the material is being deformed plastically. The dislocations start to move forming a cluster and merging into each other. The strength of the material is increased by this strain hardening.

Laboratory of Strength of Materials: Tensile stress.

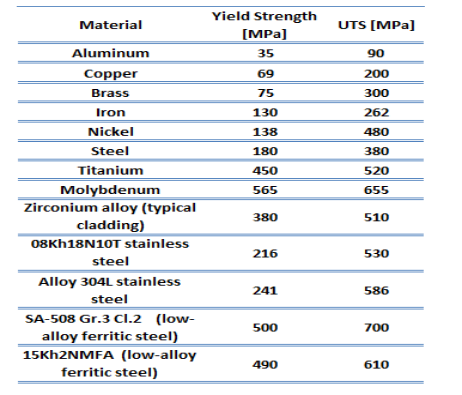

Table 1. Yield strength and UTS Strength of different Materials

Measurement Focus: Stress vs Breaking Load

Measurement focus is the main difference between the both. Tensile strength measures the stress value i.e. Force per area while breaking strength measures the total force that broke the material until the end.

Failure point

Failure point is the end point in the graph where you can see two different physically broken parts of the same material.

Why Does Each Metric Matters?

Both of the strengths matters as they both serve different purposes. For example, Tensile strength helps us in shaping and designing of different components and materials. While the total actual force material will bear until breaking is breaking strength. It can stop any accident.

Why Yield Strength Matters?

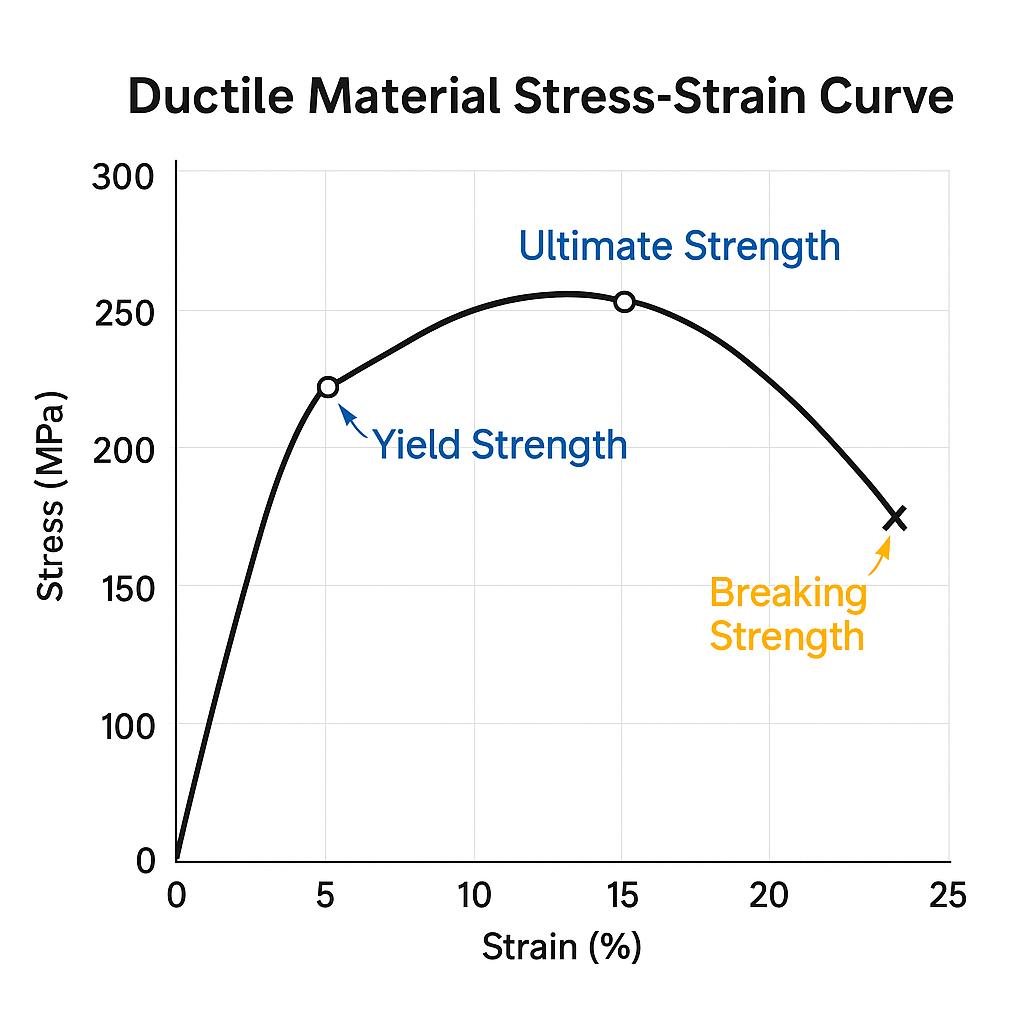

The point in the stress strain graph where you can see the straight line is turning is yield strength. Here material changes its shape. Yield strength is more important for engineer as it is used for safety factor. Breaking strength is after this. The example graph under can be seen:

Fig 2. Breaking strength vs Ultimate Strength

The stress vs strain graph is seen above. You can clearly see the turning line which is showing the material is deforming from here. The point on top is the UTS which shows the highest force that the material has faced. As the line decreasing coming to the end shows the breaking strength where material breaks in two parts.

Working Load Limit Vs Breaking Strength:

Working Load Limit refers to load that a material can bear within its safety limit. Breaking strength refers the load material will endure from start to the breaking point. The table below explains the main differences between both terms:

|

Terms |

Working Load Limit |

Breaking Strength |

|

Definition |

The maximum load a component can bear easily during normal use |

Maximum load where the component will break |

|

Factor of Safety |

Yes |

No |

|

Application |

Ropes or wires used in Lifts |

Mostly when testing the Materials strength by breaking it |

Table 2. Working Load Limit vs Breaking Strength comparison

What does WLL Mean in Practice?

WLL or Working load limit is basically the maximum force a component should endure during its normal use in an environment. It is usually the safe operational capacity. WLL is always less than the breaking strength.

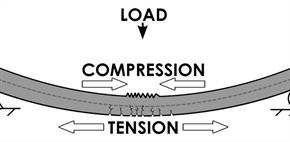

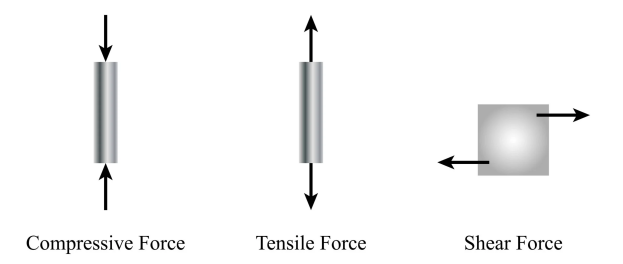

Fig 3. Compressive force, tensile force, and shear force

With Safety Factor Vs Without Safety Factor:

We can find out the working load limit by the formula which is Breaking Strength divided by the Safety factor which is often 4 to 6. If we say Without Safety factor, then we are talking about the Breaking Strength.

Field Label Vs Lab Test results:

You can simply say this using an example. Like if a rope can withstand the load of 10000 lb which is maximum load before getting breaking in Lab test results. Than the rope will be given a label of 2000 lb. in market. This is only done to consider the Safety factor of working load limit.

Minimum Breaking Strength:

MBS is the critical or lowest guarantee breaking strength which is offered by the manufacturer. An average is not offered by the manufacturer.

How MBS Guarantees?

Let us consider there are 100 components of the same thing. The manufacturer will give a certain MBS. He will claim that none of the component will fail under the given Minimum Breaking stress. That is how MBS is guaranteed.

How Manufacturers prove MBS?

MBS is guaranteed by the Manufacturer using different Standards test. One of them is the Destructive testing where a material is loaded until its failure. The Lot result must exceed or meet the guaranteed Minimum breaking strength value.

How Lots pass or Fail?

This is usually done by a quality control engineer, what he actually done is take a significant number of samples from a lot and then test them one by one. Even If one sample doesn't meet the required Minimum Breaking Strength which is guaranteed by the Manufacturer. The whole lot is rejected.

How to increase breaking strength?

Breaking strength is usually increased by a number of Factors which include:

- Heat treatment methods, such as quenching, are used to refine the grain of the material. This will lead to an increase in the hardness and strength of the material.

- Metal forming processes such as rolling and forging are used to refine/deform the grains and increase the dislocation density in the material.

- Solid solution strengthening methods can be used to add a small number of elements to the metal. These strengthening methods work by restricting the movement of the dislocation to increase the breaking strength.

How to Calculate Breaking Strength?

The breaking strength is measured by the following formula:

The breaking strength formula and Calculations

The formula for stress is:

Stress (σ) = Force / Area or cross sectional area

So Breaking Force will be = Stress (σ) X Area

Calculating units, you need

If you know the stress and the cross sectional area than breaking strength can easily be calculated in Newton, Kilograms or pounds.

From Load to stress

If you know the breaking load, then breaking stress can be calculated using the following formula:

Breaking Stress= Breaking load / Area or cross sectional area

Bolts, Fasteners and Breaking Strength

The breaking strengths of Nuts and bolts are non-negotiable in critical components. Let's discuss why it matters:

Fig4. Bolts and fasteners

Why Breaking Strength Matters in Bolts and Fasteners?

Consider an example that an aircraft is flying in the air. Can you even imagine a bolt that is loose and going to its breaking strength? A lot of forces are being exerted on every single bolt and fasteners in an aircraft. So in order to avoid any catastrophic event breaking strength comes into play.

Fig5. Fasteners design

Proof Load Vs Breaking Load

Proof load is a load that a bolt or fastener can bear without any deformation but on the other hand breaking load is the end load where the bolt will fail. Proof load is usually between 80 to 90% of the yield strength.

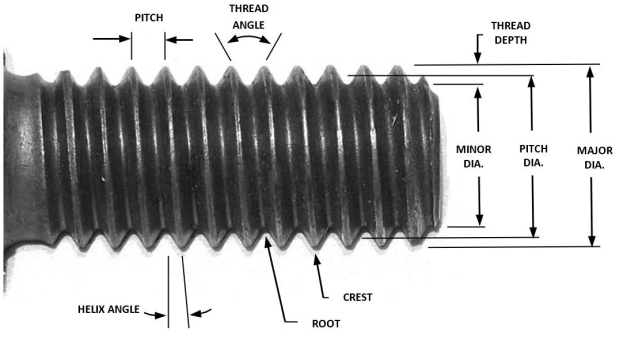

Thread Engagement for Full Strength

Thread engagement is basically referring to the bolt fully able to grip the threads on a fastener. For a bolt to reach its maximum breaking strength there must be enough thread engagement. Engaging threads for at least one diameter in steel and two diameters in aluminum is standard procedure.

Common Materials Breaking Strength:

Breaking strength of each material varies from one to another. Materials like titanium, alloy steels offer very high breaking strength as compared to Aluminum or Nylon. Let’s see typical breaking strength of some common materials and their applications.

|

Material Grade |

Typical Breaking Strength (MPa) |

Common Applications |

|

Carbon Steel (A36) |

400-550 |

Structural frames, buildings |

|

Alloy Steel (4140) |

655-1020 |

Gears, shafts, high-strength fasteners |

|

Stainless (316) |

580 |

Marine hardware, chem process |

|

Aluminum (6061-T6) |

310 |

Aircraft fittings, bicycle frames |

|

Titanium (Ti-6Al-4V) |

950-1100 |

Aerospace components, biomedical implants |

|

Nylon 6/6 |

80 |

Gears, bushings, insulators |

|

UHMWPE |

48-53 |

Medical devices, cut-resistant liners |

Table 3. Comparison of Breaking Strength for Common Engineering Materials.

Key Factors That Affect A Material's Breaking Strength

Following are the several factors that can affect the materials breaking strength:

Heat Treatment

Heat treatments like quenching can define the materials breaking strength. In this the material is heated to a certain temperature and then quickly put into water or other coolant where the material is not given a proper time to form proper grains. Tempering is done after quenching to get the toughness or strength in the material to avoid sudden plastic deformation.

Microstructure or Defects Control

During the heat treatment of the material, defects like voids or impurities are the most important factors that can decrease the strength of the material. These types of defects can be removed by controlled forging and rolling. These metal forming processes are used to increase hardness and decrease the size of the grain in the direction of the rolling process.

Temperature or Environment

The corrosive environment, such as chloride, can decrease the life of the material. The grain boundary sliding and higher movement of atoms is the key factors to decrease the strength of the material at higher temperatures. Similarly, lower temperature decreases the mobility of dislocations and thus leads to sudden plastic deformation of components.

Loading Speed

If you apply a higher loading speed on the material, then it shows brittle failure due to not having time to deform plastically. Lower loading speed on the materials shows the plastic deformation, and it will take some time to deform as compared to a higher loading speed.

Conclusion:

Breaking Strength is very important and should always be in our mind. Yield strength, UTS and breaking strength are three different things. All of these play important role in the material strength and also in Engineering. You should always use the material within its working load limit. Always see these three things for reliability and safety especially the breaking strength. It can help us in avoiding any accidents.

FAQs

What is the difference between breaking strength and ultimate strength?

The ultimate strength is the maximum stress that a material can endure. A breaking strength is the stress at which a material breaks. The material will show necking after reaching its maximum strength and then break.

Why is the breaking strength less than the ultimate strength?

The cross-area reduction after necking and maximizing the load on this point are the two main factors for reduction in breaking strength. Due to the entanglement of dislocations at UTS point bears maximum stress. After this necking start reducing the strength. That is why breaking strength is always less than the Ultimate strength.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

How to Get Custom Guitar Picks? -Step by Step Design & Machining Guide

How to Get Custom Guitar Picks? -Step by Step Design & Machining Guide