Look Back on 2024 CNC Technology Trends-What’s Changing?

Sep 26,2025

Sep 26,2025

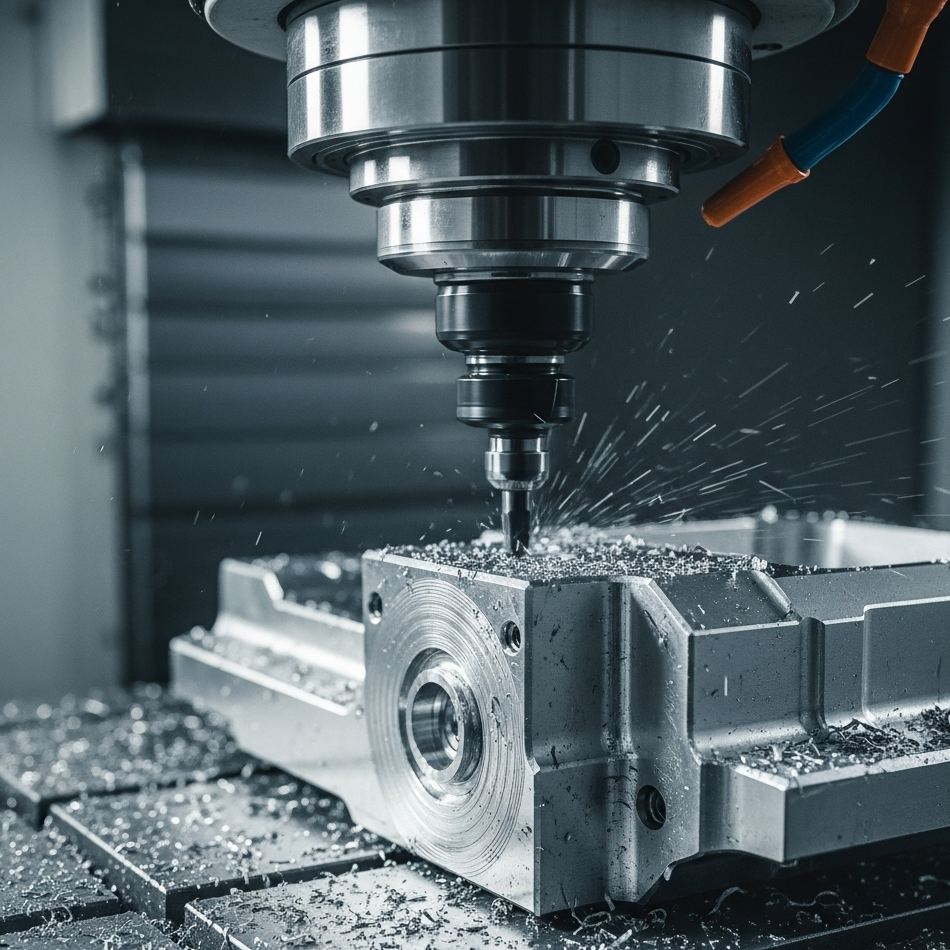

CNC is revolutionising the world of manufacturing through its pioneering technological advancements. 2024 has been a year in which a number of new trends emerged in the CNC industry that has changed the way of conventional manufacturing. We will be looking back on these trends, including AI technology and smarter machining, reshaping industries worth about $95.92 billion globally.

Look Back on 2020-2024 CNC Machining Technology

As manufacturers are more prone towards achieving higher precision and accuracy to streamline their manufacturing process. Out of which the incorporation of advanced technologies in production industries increased remarkably. When we look back in the era of 2020 to 2024 industry showed a major shift from traditional manufacturing to more smarter, automated manufacturing.

Lights-Out Automation

One of the most remarkable revolutions in cnc was the rise of lights-out automation. Introduction of automation has increased the reliability and effectiveness of the process. As it offers real time analysis of the component manufacturing. Which not only ensures its precision but speeds up the process by reducing reliance on manual labour.

Advanced Tooling

The introduction of advanced tooling in CNC technology 2024 has changed the way of manufacturing any precision component. Integration of IoT enables analytics to evaluate the tool performance and adjust processes dynamically. Such innovations strengthened competitiveness by:

- Minimizing Downtime

- Improving decision-making

- Ensuring consistent quality in precision parts.

Connected Productivity

Last but not least, another key advancement was the rise of connected productivity in CNC latest machining. It involves the integration of specialized software and digital tools. These are used to collect real time data while manufacturing.

A central metric here is Overall Equipment Effectiveness (OEE). OEE evaluates availability, performance, and quality to maximize machine output. This connectivity not only improves efficiency but also supports predictive maintenance.

2024 to 2025 CNC Machining Trends: What’s Changing?

Moving into 2025 from 2024 has marked CNC as an integral manufacturing technique across multiple industries. The use of advanced software and tools such as CAM IoT has made CNC highly effective for producing complex and precision parts. In addition, there is an evolution of AI toolpaths making the CNC more effective, innovative, and attention-grabbing.

Pioneering Developments in CNC Machining

To better understand these shifts, the table summarizes the main areas of change in CNC machining. Here, we have also illustrated their driving forces and expected impact on the industry.

|

Category |

Focus Area |

Key Drivers |

Impact / Outlook |

|

Market Growth |

Global Expansion |

IIJA, CHIPS Act, Inflation Reduction Act; investment in infrastructure & tech |

CNC market projected to reach $129B by 2026; strong demand in automotive, defense, medical, aviation |

|

Smart Manufacturing |

Digital Transformation |

Smart factories, digital twins, predictive maintenance |

Enhanced production resilience, real-time monitoring, reduced downtime |

|

Resourcing Strategies |

Localized Supply Chains |

Pandemic recovery, geopolitical tensions, |

U.S. production gains competitiveness; improved agility, shorter lead times |

|

Economic & Industrial Impact |

Workforce & Industrial Policy |

Job creation, reshoring initiatives, automation adoption |

Stronger U.S. manufacturing base, reduced global risk exposure, autonomous production environments |

AI Technology Trends

Integration of advanced technologies in CNC is shaping its future. For example, the 4.0 technologies which include:

- Internet of Things (IoT)

- Data analytics

- Artificial intelligence (AI)

Not only these technologies, but the use of 3D printing or additive manufacturing is reforming the CNC. With this additive manufacturing, industrialists can develop parts with a complex core structure with accuracy and minimal wastage of material.

AI Toolpaths

Incorporating AI tool paths in CNC has enabled optimal utilization of material, reduced cycle time and elongated tool life. More adaptive and smarter strategies are built using these tool paths, such as AI, ML(Machine learning), Genetic Algorithms (GAs) and Simulated Annealing (SA).

AI Quote

Another remarkable development seen in the CNC is the AI-driven quoting system. AI quoting systems are emerging as a fast and automated way to estimate machining costs.

But comparing such quotes with expert-driven quotes, such as TUOFA Precision Machining's will add real-world experience. They highlight technical insight and offer tailored solutions; and they serve clients from all over the world with CNC precision machining for nearly 20 years. AI alone can't fully replicate these.

Materials and Processes in CNC Machining

CNC machining enables engineers to work with a vast range of materials depending on their requirements.

- For Light weight and durable components Aluminium is preferred as it is highly resistant towards corrosion.

- Whereas for components which require higher strength titanium grade supper alloys are preferred.

Here we have made a brief breakdown of material used in CNC:

Light Alloys Machining

For the production of components where strength and low weight are key requirements, such as in aerospace components, light alloys are utilized. Aluminum alloys, including 6061-T6 and 6063, and 7075. These are the most commonly used materials in CNC. It offers a high strength to weight ratio as well as being super durable and resistant to corrosion.

Superalloys & Titanium Machining

Titanium Grade 5, also known as Ti-6Al-4V, is one of the most widely used titanium alloys in CNC machining. It typically contains 6% aluminum and 4% vanadium. Grade 5 titanium offers high mechanical strength, biocompatible and corrosion resistance. It is best suited for CNC milling and turning where precision and surface quality are critical.

Engineering Plastics Machining

POM (Polyoxymethylene), which is also known as an engineering plastic, is extensively used in CNC. Components made with POM show high stiffness, dimensional stability, and low friction. That is why it finds its application in the production of gears, bearings, and automotive parts.

5-Axis & Mill-Turn Machining

When Industrialists need to manufacture high-end precision components with CNC, they now utilize 5-axis machining or mill-turn. Such advanced methods allow for machining complex geometries in a single setup. They make the production time effective by reducing cycle times and improving accuracy.

What Is Green Manufacturing and CNC Machining

CNC machining has successfully enabled the production of components within the parameters of green manufacturing. As it offers production of various parts with:

- Minimal material waste through optimized toolpaths and precise machining

- Ease of recycling by separating and reusing scrap materials

- Sustainable CNC material utilization with eco-friendly alloys and engineering plastics

- Adoption of renewable energy sources to reduce carbon footprints

Energy Management

Now, CNC works with smart factory systems, which enable real-time monitoring of power usage, predictive maintenance, and energy optimization. Manufacturers are opting for sustainability by using renewable energy sources such as solar and wind energy.

Scrap & Recycling

One of the strongest contributions of CNC machining industry to green manufacturing is the reduction and recycling of scrap material. Not only this the components manufactured through cnc can be recycled, reducing waste.

Standards & Reporting

Technology CNC compliance with green manufacturing standards such as ISO 14001. Many companies now publish sustainability reports. These reports track metrics like energy consumption, emissions, and recycling rates.

Who Benefits From CNC Machining?

Aerospace & Defense

Precision parts for aircraft and defence systems. High reliability meets strict standards.

EV & Battery

Complex components for electric vehicles and batteries. Ensures efficiency and durability.

Medical Devices

Intricate, high-precision parts for surgical tools and implants. Meets stringent safety requirements.

Robotics & Automation

Custom parts for robotic systems. Enhances performance and adaptability.

Market Outlook in CNC Machining

The CNC industry is experiencing steady growth as manufacturers continue to demand precision, automation, and scalability. Adoption of cnc is now not limited to traditional metallurgy industries, but it has expanded to:

Automotive Industry

- Aerospace Industry

- Medical Industry

- Electronics Industry

- Defence and Military

- Energy Sector

Here is the current market growth of CNC

- Market size:USD 79.2 Bn (2025) → USD 194.3 Bn (2034)

- CAGR: 5%

- Largest region:Asia-Pacific (34.9% revenue share, 2025)

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

CNC Machining Lead Time: How to Get Your CNC Machined Parts Faster

CNC Machining Lead Time: How to Get Your CNC Machined Parts Faster