What Is Residual Stress? Causes, Types & Measurement

Feb 14,2026

Feb 14,2026

Residual stress is the silent force hidden within your components. It may change dimensions, reduce the life of components, and disrupt delivery schedules without giving any noticeable warning or indication. In many manufacturing projects, distortion, rework, and early failures are not the result of poor design. Rather, they are the result of internal stresses that have been introduced during the machining, welding, and heat treatment processes. This article will help you understand what residual stress is, where it comes from, and how you can control and relieve it. Design and production decisions with a trusted production partner helps in controlling residual stresses. Here is a complete guide about residual stresses. Stay tuned!

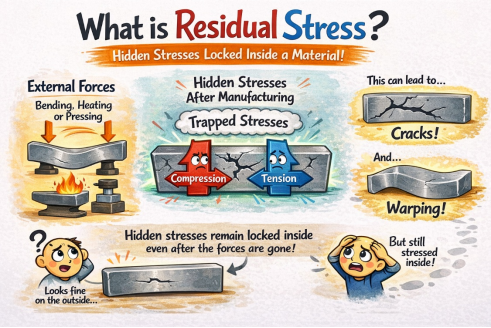

What Is Residual Stress?

Residual stress is the internal stress that is self-balanced and remains in the finished part after all external forces and heat loads are removed. In practical projects, there is always one question that is: “Is the residual stress already present in material or does it come in the finished part?”The truth is, both types exist. The residual stress in the material is a result of how the raw material is processed. While the residual stress in the finished product is created through machining, forming, welding, and surface treatments.

For more better understanding, below links explain what is residual stress:

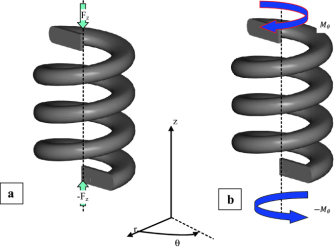

One simple example which we can consider is: Compression Spring. When it is subjected to plastic forming and then released, some level of residual deformation remains locked into place. It is the hidden stress and is not visible but effects the performance.

All Engineering Materials Have Residual Stress?

From a manufacturing perspective, residual stress is essentially present in every engineering material. For metals, residual stress is present after rolling, forging, casting, welding, and CNC machining. For plastics, residual stress is present after injection molding, extrusion, and thermoforming. The magnitude and location of residual stress can be different, but the presence of residual stress is a reality that cannot be avoided in industrial production.

Basic Requirements for Residual Stress

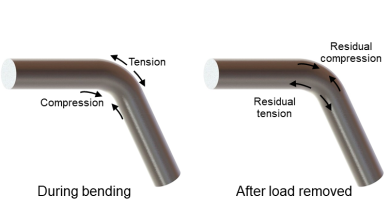

Strain can include contributions from elastic loading, plastic deformation, or temperature differences. When the external load is removed after nonuniform plastic or thermal deformation, incompatible elastic recovery in different regions leads to locked-in residual stresses. Residual stress would not exist if a material could not recover elastically at all.

Residual Stress in Engineering Materials

In the case of manufacturing industries, understanding the residual stresses in various materials helps in optimizing the process for machining and inspection activities. The following are the differences in the reactions of metals and plastics to some machining and inspection processes:

Residual Stress in Metal

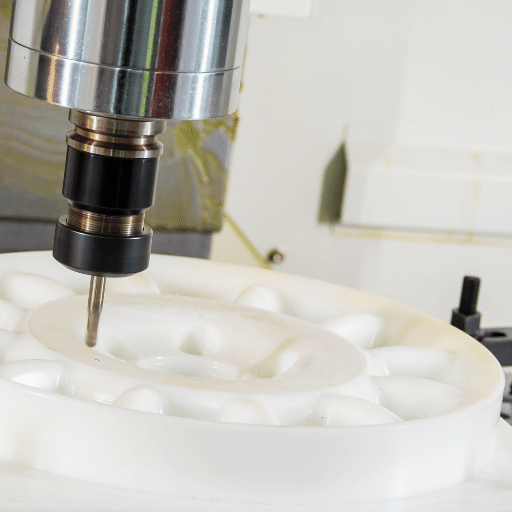

Internal residual stresses can develop in metal parts from rolling, welding, heat treatment, and even from, CNC machining. The cutting forces and the resulting heat mostly serve to affect the outside surface of the part. In most cases, residual stress is just beneath the surface of the part and lies within 0.05 to 2 mm deep.

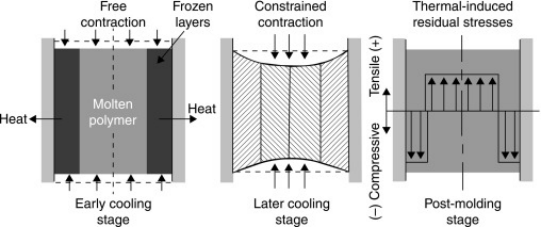

Residual Stress in Plastics

For Plastic parts, Residual stresses are induced by non-uniform cooling, atomic orientation, and shrinkage phenomena. When high levels of internal residual stresses are present, warpage, stress whitening, and delayed failures are common.

Difference: Residual Stress in Metal & Plastics

Here we are going to talk about the difference of the residual stresses between metal and plastic parts or applications:

|

Features |

Residual Stress in Metal |

Residual Stress in Plastics |

|

Stress Source |

Arises mainly due to plastic deformation and temperature gradients |

Arises mainly due to the differences in cooling, shrinkage, and the alignment of the molecules during the molding or extrusion process. |

|

Location |

Typically found in a concentrated area near the surface |

May be distributed over a wider area of the part and could extend across the entire cross-section. |

|

Temperature sensitivity |

Tends to be more stable after proper stress relief heat treatment. |

Temperature dependent in service. Stresses may relieve or redistribute over time. |

|

Problem in Manufacturing |

Distortion may occur due to machining, fatigue cracks, and reduced fatigue strength |

Warping, dimensional imbalance, stress whitening, and stress cracking may occur due to environment |

|

Precautions in production |

The best cures are process optimization and heat treatment after machining |

mold designs, selective cooling, materials choice, and cycle optimization |

What Causes Residual Stress?

Residual stress is caused mostly by inhomogeneous deformation or temperature gradients that occur during the manufacturing process. Some of the common residual stress induction mechanisms are discussed here.

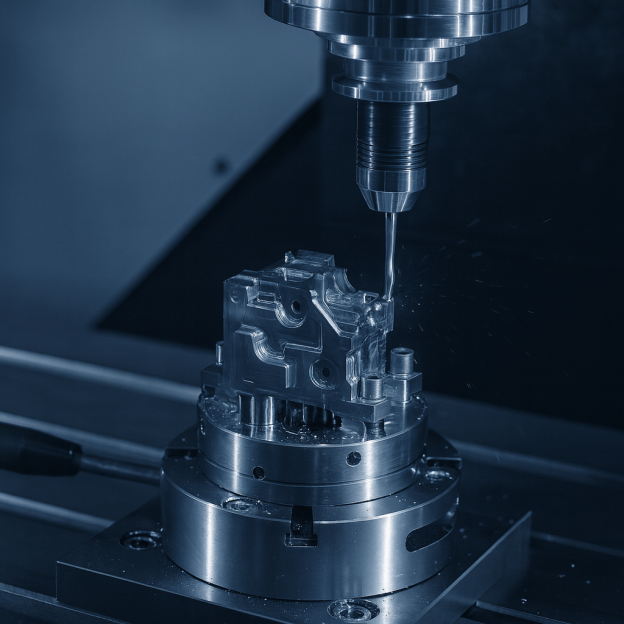

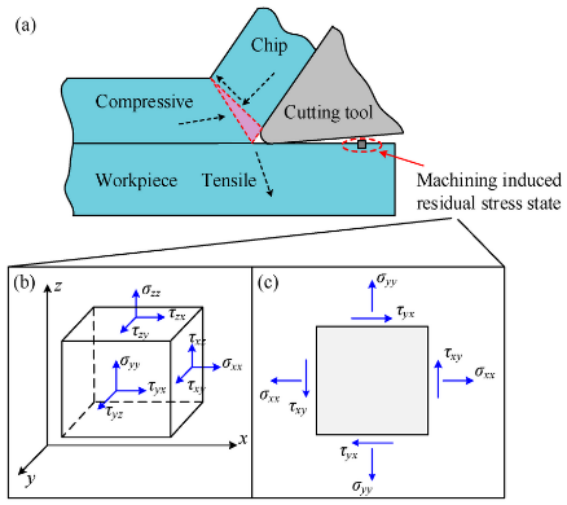

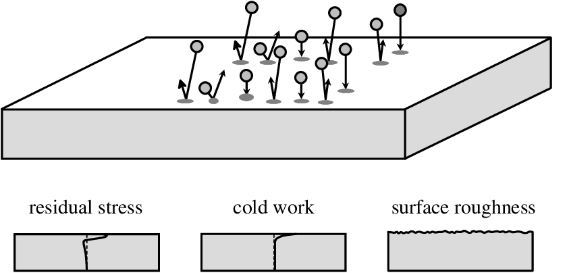

Machining-Induced Effects

Machining process effects appear as a result of high cutting forces, worn-out cutting tools, and irregular feeds. Small and concentrated areas are forced into plastic flow. Inadequate finishing process control is usually responsible for residual tensile stress. On the other hand, carefully controlling process parameters can also introduce residual compressive stresses, which are beneficial.

Temperature Variations

The role of temperature differences cannot be overlooked because they play a crucial role in the introduction of internal or residual stresses to a material as they expand or contract rapidly. For instance, during a welding or quenching process, the material will expand rapidly at first and then cool down. The final outcome is that a residual stress will occur as the material cools down due to the unevenness of the process.

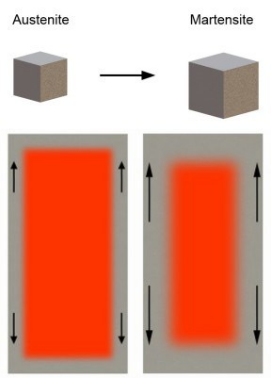

Phase Transformation

Phase transformations is also a cause for residual stress. As an example, in the case of steels phase transformations such as the conversion of austenite to martensite involve a volume change. This change can generate residual stress without any external load being applied.

Surface Treatment

Surface treatments are intentional alterations to the surface by methods such as shot peening or laser peening, embedding residual compressive stress onto the surface. This improves the fatigue resistance.

Effect of Residual Stress

Residual stress has neither a positive nor a negative effect. It all depends on the sign, position, and the amount of residual stress relative to production plans.

Passive Influence

Excessive surface tension can cause problems such as fatigue life issues and dimensional instability. You may face:

- Tensileresidual stress will reduce fatigue life

- After material removal, unexpected distortion

- Tolerance varies based on variation in sizes

These issues add to the delivery risk and rework costs.

Positive Influence

Residual stress, compressive residual stress, has several useful benefits for materials and parts. It boosts effective strength and load-bearing capacity—for example, autofrettage lets thick-walled pressure vessels handle higher pressures, while prestressing greatly improves tensile strength in concrete and tempered glass.

What Are the Benefits of Residual Stress?

Residual stress can be a very useful tool in manufacturing if you treat it correctly. Otherwise, it can be a major problem. Some of the benefits are discussed here:

Enhance Fatigue Life of Parts

The surface compressive stresses can decrease the tensile stress. Components subjected to during cyclic loading first need to overcome the compressive residual stress before tensile range of stress begins. In numerous industrial parts, this can increase fatigue life considerably, anywhere from 30% to 300%, depending on the material and the surface treatment process used.

Improve Wear Resistance

Compressive stress improves the stability of surface hardness and resistance to micro-pitting. In applications like gear and sliding components it is particularly useful.

Enhance Corrosion Resistance

Reduced sites for crack nucleation decrease stress corrosion cracking in harsh environments.

Greater Dimensional Stability

Uniform internal residual stress reduces distortion during machining. This helps in to maintaining consistent dimensions with tight tolerances in mass production.

Types of Residual Stress

Residual stress can appear in different forms within a component. It is important to understand the different types when you are selecting inspection techniques and quality goals. From a manufacturing perspective, residual stress can be generally defined based on how it is distributed within a component and whether it is a source of compressive or tensile stress. Identifying the type of residual stress within your components will enable you to better evaluate the risks of distortion, fracture, and fatigue failure. It will direct you on the process controls to adopt to improve the reliability of your components.

Residual Stress Types by Scale

Residual stresses can be classified based on the extent to which they are distributed in a component. This classification system will inform you of whether the stress is more likely to affect the overall shape of the component, the material properties at a local level, or the structural integrity of the component.

Macro Residual Stress

Macro residual stress acts on the entire part or on large areas of the component. It is caused by non-uniform cooling, welding, and/ or non-uniform heat treatment. Macro residual stress results in overall distortion, bending, twisting, and loss of dimensionality after machining or stress relief operations.

Micro Residual Stress

It is present between individual grains in the material. Micro residual stress is caused by local plastic deformation which takes place during forming, rolling, forging, and machining operations. It influences local strength and fatigue properties, causing early initiation of cracks at the grain level.

Microstructural Residual Stress

It occurs in the grains and at the interfaces of the phases in the crystalline microstructure. Phase transformations, lattice mismatches, and thermal expansions of phases during heat treating processes are causes of this type of stress. This stress directly impacts the long-term stability and exhibits local differences in terms of hardness and fatigue resistance. It largely occurs in alloys and heat-treated components.

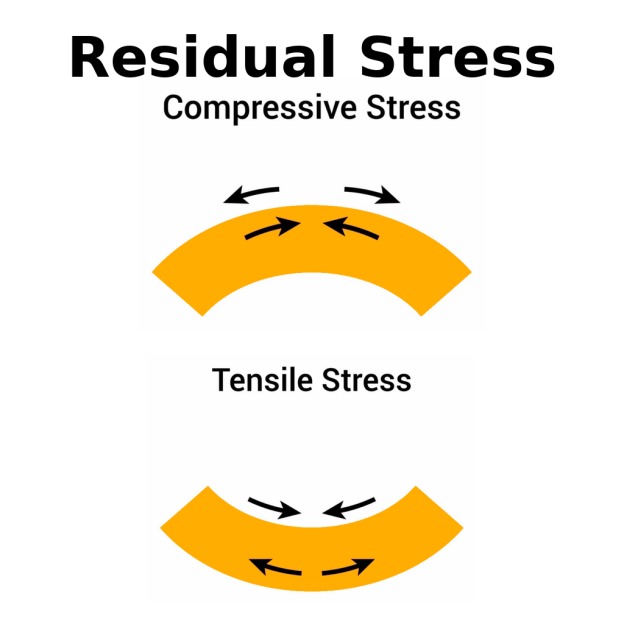

Residual Stress Types by Sign: Compressive vs Tensile

From the manufacturing and performance point of view, residual stresses are also classified based on whether it is tensile or compressive. It depends on the direction of the stress, which has a direct effect on fatigue and crack formation.

Compressive Residual Stress

Compressive residual stresses generally increase the fatigue life by restricting crack development. They inhibit crack opening and slow down the growth of cracks. Compressive residual stresses can be induced through manufacturing processes such as shot peening, laser peening, controlled finishing, and burnishing. They also reduce the possibility of stress corrosion cracking.

Tensile Residual Stress

Tensile residual stress commonly results in a shorter fatigue life due to premature crack development. The tensile nature encourages crack opening and facilitates in crack growth. Welding, aggressive machining, grinding burns, and rapid cooling are the main culprits in introducing these residual stresses. Since crack opening is facilitated, the possibility of stress corrosion cracking increases.

How to Measure Residual Stress?

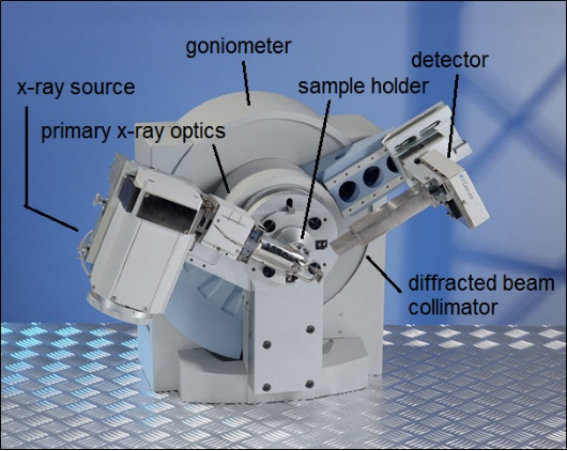

There are many methods of residual stress analysis. The common methods can be broadly classified into non-destructive method, semi-destructive method, and destructive measure method. However, in reality, the selection of the method is entirely dependent on the desired level of accuracy. Industries may be required to prove conformance to ASTM E915 and ASTM E2860 standard tests for residual stress testing.

Non-Destructive Method

Non-Destructive methods measure residual stresses without damaging the test piece. Thus, the specimen retains its usability after performing residual tests on it. This method can be particularly employed when the piece under consideration is already finished and when it is of high value.

- X-ray Diffraction

X-ray diffraction is considered to be the preferred non-destructive method to determine residual stress. This method measures small changes in crystal lattice structure to identify surface residual stress. X-ray surface analysis gives fast and reliable results to control quality and validate processes.

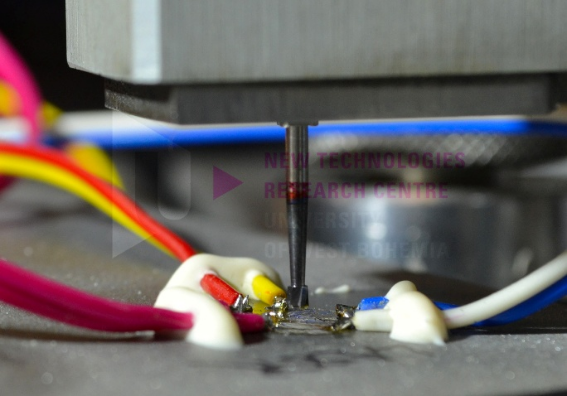

Semi-Destructive Method

Semi-destructive techniques involve residual stress measurement after a controlled disturbance is introduced. The component is still functional. This is a better option given a component, especially in situations where near-surface data is needed but the component cannot be destroyed.

- Hole-Drilling Method

Residual stress is measured by creating a small hole in the material and then observing relaxation of the surrounding material. Consequently, this relaxation is used in order to estimate the distribution of the stress below the surface.

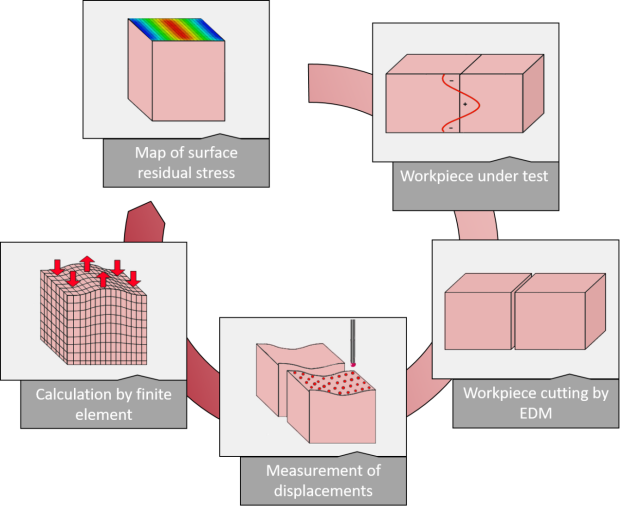

Destructive Measure Method

Destructive methods are used when it is required to have a full stress distribution inside, and when it is no problem to sacrifice the test piece. They offer greater precision than methods for which only surface information is gathered.

- Contour Method

The contour method is a technique of measuring residual stress in a part by sectioning it into two pieces and measuring the resulting deformation of the cut surfaces. The measured values of deformation are then used to calculate the complete residual-stress profile of the cross-section, and hence the method is very suitable for the procedures of validation and failure analysis.

![]()

How to Control or Relieve Residual Stress?

From a manufacturing viewpoint, residual stress cannot be completely avoided. It definitely can be controlled and relieved with intelligent design decisions. Most of the time, the material is not the problem; rather, it may have to do with geometry, unbalanced machining, or lack of steps for stress relief in the process. By addressing these upfront, the risk of distortion can be reduced, and the product's dimensional stability can be improved. Following are the points discussed that may control residual stress:

Optimize Design of Parts

In order to reduce the residual stress, the start of the design of the parts should ensure a smooth transition between the different regions, in addition to avoiding the use of thin walls or sudden changes in wall thickness. This would ensure that the deformation and stresses in the parts are evenly distributed and residual stress is reduced, in addition to avoiding any bending or twisting after the machining operation is over.

Adjust Machining Parameters

The residual stresses in CNC machining can be directly influenced by factors such as cutting speed, feed rate, depth of cut, and tool geometry. It is possible to reduce the surface tensile stresses to a minimum and introduce more desirable compressive stresses on critical surfaces by optimizing these factors and selecting an optimal order of roughing and finishing. This will result in improved dimensional stability and increased fatigue life.

Heat Treatment

Stress relief heat treatment is one of the most successful techniques in relieving internal residual stresses. For most common steel materials, stress relief is usually done at a temperature range of 550 to 650 ℃. This technique allows the internal stresses to relax without affecting the mechanical properties of the material, which makes it a very effective technique for pre-machining or pre-assembly purposes.

Relationship: Residual Stress vs Residual Strain

Residual stress and residual strain are closely related. Both arise from manufacturing processes like forming, machining, welding, and heat treatment. When a part is deformed or heated unevenly, some deformation is permanent while other parts want to recover elastically.

After removing the load or constraint, the permanent deformation is nonuniform. Different regions try to spring back different amounts, but they must stay connected. This incompatibility creates self-balancing internal forces—residual stress. Residual strain is the remaining permanent deformation. From a manufacturing view, both affect dimensional accuracy, fit, and long-term performance of the part.

What Is Residual Strain?

Residual strain is defined as a permanent distortion in a component due to the absence of external forces or temperature changes. Residual strain is a measure of the permanent change in geometry, which is primarily related to plastic strain.

What Are Their Differences?

Closed though, there are some different features, such as effects on parts and manufacturing risks.

|

Feature |

Residual Stress |

Residual Strain |

|

Definition |

Internal stress that is already present within the materials due to manufacturing and loading |

Permanent deformation, which is present in the part after manufacturing and unloading |

|

Nature |

Elastic energy that is stored within the material |

Irreversible plastic deformation |

|

Effect on parts |

Affects the fatigue life, initiation of cracks, corrosion resistance, and long run dimensional stability |

Impacts part geometry, flatness, alignment, and assembly accuracy of a part |

|

Measuring Techniques |

Assessed through methods like X-ray diffraction or hole drilling |

Evaluated using the dimensional inspection, CMM measurement or optical scanning |

|

Manufacturing Risk |

May lead to distortion or failure in service |

Deformation that can lead to assembly problems |

Conclusion

When it comes to controlling the process of making industrial goods, residual stress should be considered more like something to be controlled rather than something to be avoided. In uncontrolled residual stress, optimized design solutions, precise CNC machining operations, appropriate treatments of the parts' surface, and adequate measurement strategies all allow for substantially enhanced reliability during product use. An experienced machining services company can provide considerable advantages in process improvements when it comes to residual stresses with those they work with.

FAQ

What is residual stress in welding?

Residual stresses developed during the process of welding are caused by the intense local heating and subsequent rapid cooling of the weld material. During this process, surrounding material resists the phenomena of contraction, leading to the development of tensile and compressive stresses surrounding the heat-affected zone.

What is residual tension?

Residual tension is defined as any residual tensile stress or tensile stress remaining in a part after a process. Residual tension is most hazardous near surfaces or weld toes where cracking will most likely occur.

How to reduce residual stress in CNC machining?

Techniques for relieving or reducing residual stresses: optimize machining conditions, reduce wear and tear on the cutting tool, balance roughing and surfacing, perform an auxiliary heat relief treatment, and do not remove too much material.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What Is Titanium Used for? Machined Parts & Applications

What Is Titanium Used for? Machined Parts & Applications