Text Milling: CNC Engraving for Letters, Numbers, Logos in One-Stop

Sep 03,2025

Sep 03,2025

Are you tired of temporary stickers or stamps of logos? The text milling makes it possible to get permanent marks of very high precision on your workpieces. The aesthetic designs and logos can easily be made on your components. So, let's discuss the basics of this amazing manufacturing technique and its related aspects in this article:

What Is Text Milling

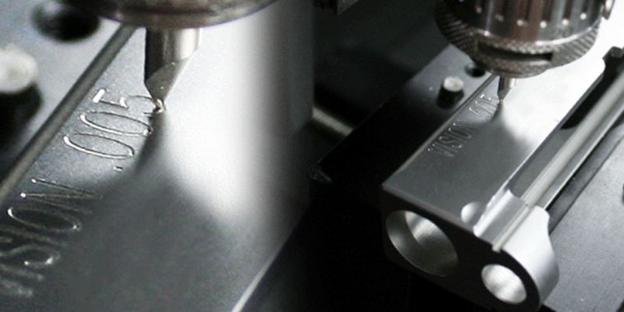

As you know, CNC is a modern machining process used in industries to get an accurate shape. One of its good features is text milling, in which you can easily make logos, numbers, and aesthetic designs. It gives precise, clean, and excellent durable results because it is controlled by the computer.

Definition of CNC Text Engraving

Have you ever thought about how these logos and texts can be engraved onto the different components? Let's discuss how it works:

In CNC machining, the computer will first interpret the image/information into the vector geometry. It is not just copying the information directly, but it converts the information into simple lines and shapes (vector). These shapes and lines work as a map to guide the tool exactly where to move. The cutter engraved the design, text, or logo onto the workpiece with high accuracy and durability.

Typical Use Cases on Machined Parts

You often see the engraved numbers, logos, and notes on different components used in our daily life. For example, the following figures show the text and logos on their components:

Why it Matters?

The logos, serial numbers, and brand names give the identity to every product. If you look at the Apple phone anywhere, it instantly identifies you as an iPhone user. Every brand is recognized through these marks, which is why text milling is an important tool.

Text, Number and Logo Engraving

A CNC text milling machine uses a different code, depending on the type of designs of text, numbers and logos. Whether it is an easier or difficult design, you don't need to be worried about precision because CNC text milling does this job with quite precision.

When to Choose Milling over Other Methods?

You will study some other techniques in this section, which are used for text engraving.

Common Methods of Engraving Letters and Logos

Laser and manual stamping are the common methods to engrave the logos and text onto the workpiece. These two methods are discussed in detail below:

Laser Engraving Text

The oldest and longest-lasting method to engrave text onto components is laser. The text onto the workpiece can be achieved by using a high-energy and focused laser, which leads to burning components. The figure below shows the focused laser falling onto the components, which leads to the evaporation of material from the surface and engraving text.

Manual Stamping Text

It is a traditional and cost-effective method in which the text can be written onto the workpiece by using a hammer or a steel die presser. You can use this method only when you need low precision and the workpiece is strong enough to bear the pressing load.

Using Labels

Labels are stickers, and you cannot use them on machines. The stickers will easily peel off with time due to operating conditions like heat and vibrations.

Milling vs Laser for Part Marking

The choice of milling or laser methods depends on the application and operating conditions in which you want to use the component. If you wants durability, high precision for marking, then you should go with the text milling process.

The laser can be used when you need cost-effectiveness and precision. If you can compromise the precision, then manual stamping is the most effective method to make markings.

Advantages and Disadvantages of Text Milling

Table 1: Advantages vs Disadvantages

|

Advantages |

Disadvantages |

|

It provides an integrated finish. |

A skilled CAM programmer is required to operate it. |

|

It makes long-lasting marks on the workpiece. |

Significantly increases production time with cost. |

|

Fully automated process ensures consistency. |

Not suitable for very hard or already-finished surfaces. |

|

The high precision of text can be achieved in this method. |

Requires expensive, special tooling. |

Text Milling in Metal vs Plastic Parts

You know both metal and plastic are different materials in terms of chemical, physical and mechanical properties. So, the method to use the text milling will be different for these materials. Let's discuss how:

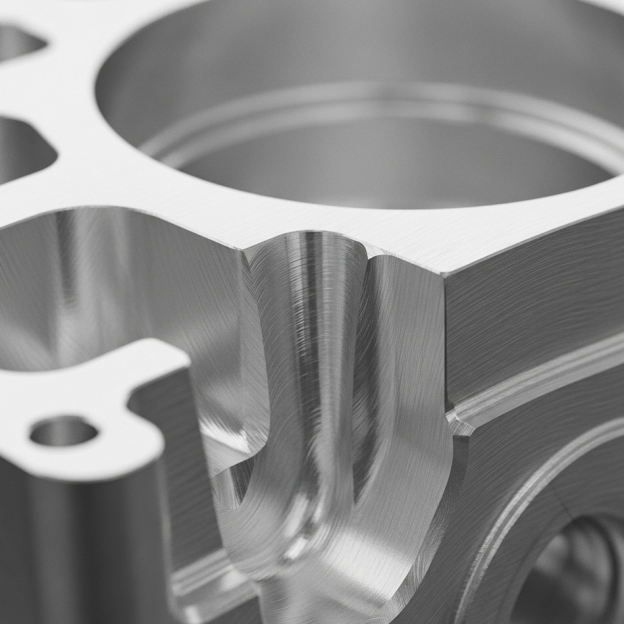

Adding Text to Metal Parts

The addition of text onto the components of metals such as aluminum, stainless steel, titanium, etc., requires a high spindle speed due to their high strength and durability. Secondly, you need to control the depth of cut on the component very carefully to avoid breakage and loss of material.

Adding Text to Plastic Parts

For the addition of text onto the plastic parts, you will mainly face milling difficulties and differences. As we are all familiar with Polyvinyl Chloride and Acrylonitrile Butadiene Styrene (ABS) plastic materials, it is very easy to cut them due to their low melting point. But the generation of excessive heat leads to the breakage of plastic material.

Text Design Basics for Machined Parts

Are you familiar with text design basics? If not, then this section is for you:

Relief Mode: Raised vs Recessed

If you want text that is easy to read and resistant to wear, then raised text is good. This can be done by removing the material around the text. If you want the cost-effective and fine detail for writing text onto the parts, then the recessing method is the best. This works by engraving letters into the material. Recessed saves the materials of the part as compared to raised.

Path Type: Centerline vs Outline

- Centerline Engraving

This method is suitable for small text and can be used for serial numbers, and codes. In centerline engraving, the tool follows the center of the line like a pen.

- Outline Engraving

This engraving can be used when you need more visible text. In this, the tool cuts around the logos, text, or shape.

Minimum Feature Size for Readable Letters

Now, you will learn about the size issue in engraving text:

Character Height Guidelines

At least 2.5mm height of a letter is required to be visible on the workpiece.

Line Width to Cutter Diameter

The line width to cutter diameter determines whether your cutter is following the desired shape or not. If you use a cutter with a diameter half of the intended line width, then you can achieve good readability.

Text Placement for Structural Safety Tips

You should be careful while engraving the text onto the part because the weak spots of the components can result in a decrease in strength. So, follow these structural safety tips to place the text onto the parts:

1. Depth Limits: Avoid the depth of engraved text by more than 10% thickness of the component.

- Edge Clearance:Avoid the text near the edge, because from this area, a little loading leads to cracking of the material.

- Uniformity:It is recommended to maintain the depth of the lettering the same across the part.

Stress Flow: Avoid engraving the text in high-stress areas to avoid a decrement in structural integrity of the material.

Post-Machining Considerations: First, do the engraving process and then do the surface treatment. Otherwise, it will damage the coating of material.

Selecting Fonts for CNC Text

This section will provide you with the information to select the fonts for CNC text:

Single-Line Fonts for Engraving

Single-line fonts are best to use when you are writing small text and there is a shortage of time. This fast writing of text is due to a reduction in toolpath length.

TrueType to Vector Conversion

True type to vector conversion is done because it ensures the complex text onto the component. This conversion from TrueType to vector can be done by using a different design program.

Fixed-Width Fonts for Serial Numbers

It is recommended to remain consistent with fixed-width fonts because they allow you to read easily.

CJK Support, Special Symbols

CJK abbreviations are the Chinese, Japanese, and Korean. CJK symbols are important, or another symbol is used when items from these countries are exported.

Stick Font Sources

Through the CNC libraries, it allows you to stick to the font.

CAM Workflow for Text to G-Code

It is an interesting section of this article where you will study a complete workflow from CAM to G-code for text engraving.

Step 1 Create Text Sketch

The very first thing which you will do is sketch in CAD software. In sketching, you simply orient the letters in correct composition.

Step 2 Vectorise Fonts

After CAD software, CAM software performs its function. You will convert the text into a vector, so CAM can generate toolpaths for CNC engraving.

Step 3 Select Toolpath

Mostly, there are two main tool paths used in the CNC engraving, i.e., Engraving or Pocketing. These engravings can be chosen according to the design of the component.

Step 4: Define Cutting Data

You can set the parameters for text engraving by considering the parameters below:

- Feed Rate

- Spindle Speed

- Depth of Cut

Step 5 Simulate Toolpaths

First, simulate to find the actual tool movement and collision (if it occurs).

Step 6 Postprocess, Prove, Run

At the last step, you will generate a G-code, perform a dry run and then finally execute the job on the CNC machine.

Text Milling Materials and Surface Finish

Every material behaves differently in text milling because some are easily machinable, and some are very difficult. Let's discuss the properties of different materials for text milling in this section:

Metals: Aluminium, Steel, Titanium

You know the colors of most metals, such as Al or stainless steel, are bright, so after text engraving, these metals offer great contrast. This will make the text more prominent for a longer time. Some durable and hard materials like titanium are very difficult to machine, which leads to to engraving of text onto the component being very difficult.

Plastics: ABS, PC, Acrylic

Plastics such as ABS, PC, and acrylic are easy to machine, but excessive or higher speeds of tool on the text lead to a decrease in the structural integrity of the plastic.

Other Options

Other materials like composites gives the higher tool wear as compared to metals and plastics.

Surface Finish after Text Milling

It is better to do text milling before you apply surface finish methods. Because after surface processes, text engraving can damage the coating or paint, etc. Further, surface finish processes will increase the readability of the engraved text.

Paint, Powder, Anodise Compatibility

Table 2: Surface finish compatibility

|

Process |

Method & Description |

|

Anodize |

Always engrave AFTER. Anodising is a hard surface layer. Machining through it exposes raw, unprotected metal, ruining the finish and corrosion resistance. |

|

Paint & Powder Coat |

Engrave AFTER for a contrasting look (raw metal shows). Engrave BEFORE if you want the text filled and to be the same colour as the coating. |

Free CNC Text Engraving Software List

If you are searching for free text milling software, then you are at the right spot. In the section below, you can find the free text milling software:

Free CNC Engraving Software

This section presents you with some free software for vector font design and CAM programming software.

1. Vector font design software

To design the vector font and G-code output, you can use Inkscape with Gcodetools software.

2. CAM programming software

To text sketch, you can use the Fusion 360 software.

Paid Options with Tiers

There is some paid software, such as VCarve Pro, that gives more features and precision. Another paid software is Mastercam, which gives a high-end solution.

Blend Your Text Milling into Your Machined Parts One-Stop

If you are thinking that text engraving is the second and optional preference. Then, this is wrong because adding logos and text gives a boost and identity to your product. TUOFA is one of the Chinese companies that gives you highly precise text engraving on your parts. They have highly advanced machining tools, such as CNC, that give you precise and cost-effective engraving of text on your parts.

Conclusion

Text milling is important for industries because it gives the identity to your products by engraving the text, logos on your parts. You can choose the different options to engrave the text onto the component, from Manual stamping (cost-effective method) to CNC text engraving (which gives you higher precision), according to your application.

FAQs on Text Milling

What materials work best for text milling?

Materials having good ductility will work well for text milling, such as Al and low-carbon steel. It is difficult to write the text on the brittle materials.

How deep should CNC text be?

The depth of engraved text on machined parts must not exceed 10% of the thickness of that part.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What Is Hard Turning for Precision Parts-A Complete Guide

What Is Hard Turning for Precision Parts-A Complete Guide