What Is Duralumin Material? Know Its Properties & Applications

Jan 20,2026

Jan 20,2026

Duralumin is an incredible aluminum alloy when it comes to high specific strength and light weight. While it has one of the lowest densities out of all structural metal, its strength is really impressive. Since its discovery in 1909m, duralumin is highly regarded by engineers across a broad spectrum of industries like aircraft manufacturing. Be it fuel efficiency, energy saving or fatigue performance, duralumin is the perfect solution. Let's learn more about this remarkable material.

What Is Duralumin Alloy?

Duralumin is an alloy of high-strength and lightweight aluminum belonging to the Al-Cu alloying system. It is an incredible material which preserves the advantageous properties of aluminum while giving strength that is comparable to steels. For weight conscious applications like aerospace components, duralumin metal is no less than a wonder. Importantly, modern industrial standards categorize it as 2000-series aluminum alloys.

When Was Duralumin Discovered?

Duralumin alloy was first discovered at Dürener Metallwerke in Germany. In 1909, the German metallurgist, Alfred Wilm observed that Al-Cu alloy increased strength after leaving it as it is with the passage of time. This phenomenon can be referred to as “natural age hardening”. Due to its astonishing properties, duraluminum soon came into industrial production. By 1911, it began to be used in the making of aircraft structures.

Other Names of Duralumin

Depending on the location, standards and applications, duralumin is also refereed by other names. Below are some examples:

- Duraluminium: In Europe, it is also called by this name.

- Duralum: It is sometimes commercially called by this name.

- Dural: It is a widely used abbreviated form.

- Dural metal / dural materials: It may be referred by this name to indicate high strength as in duralumin.

Is Duralumin Magnetic?

Generally, aluminum metal is non magetic in nature and so does its alloys. Duralumin also does not retain magnetism and it does not show magnetic attraction. It's non-magnetic nature has certain advantage. As an example, components made up of duralumin do not magnetically interfere in aircrafts avionics.

Chemical Composition of Duralumin

Generally, duralumin contains 90-95% aluminum, 3-5% copper, 0.5-1.5% magnesium and 0.3-1% manganese. While copper is the main strengthening element, manganese and magnesium refines grain structure and improves precipitation respectively. Occasionally, silicon is added in a very small amount to improve castability. This combination produces dural material with an impressive strength, fatigue resistance and toughness.

Why Chemical Composition Matters?

The above stated composition of duralumin is very significant. Copper as the main alloying element substitutes aluminum atom sites in the lattice. As copper atom is smaller than aluminum, this mismatch of atomic sizes creates lattice distortion. Thus, dislocation movement is impeded in the coherent and semi coherent phases of q' and q” respectively. As a result, yield strength at level that are unexpected to aluminum are achieved in 2000-series aluminum alloys.

What Are the Properties of Duralumin?

Duralumin posses really unique properties. It has a low density that it suitable for low weight applications. On the other hand, its strength matches that of steels. Duralumin endures repeated loading at high stress levels. In short, it's unique properties are unmatched by any other common material, that is why duralumin is usually used to manufacture mechanical parts.

Hardness

Duralumin offers a moderate to high hardness. On the Brinell scale is it around 120-150HB. Hardness values change during precipitation hardening. Actual values depend on the composition and heat treatment state.

Tensile strength

Duralumin is one of the strongest aluminum alloys. While the tensile strength of pure is only 90-100MPa, the tensile strength of duralumin exceeds 450 MPa in its peak aged condition. Its high load bearing ability produce high performance parts for long term use.

Elongation at Break

The elongation at break for duralumin is lower than other aluminum alloys. The ductility of duralumin gets traded off with its high strength. It has a moderate ductility of 8-20%. Parts composed of duralumin still show a warning before failure. A sudden fracture is prevented.

Fatigue Strength

Duralumin shows fatigue strength more than other aluminum alloys. Parts composed of duralumin can endure high cyclic loads. Fine precipitates distribution and controlled grain structure helps delay crack initiation.

What Are Advantages of Duralumin?

The exceptional properties of duralumin give it several unique advantages. It offers an ideal combination of strength, light weight, and manufacturability. The low weight of components helps to save a lot of energy in mobile components. In addition to it the high strength endures high loads. Good machinability helps to manufacture precise components with tight tolerances.

Good Mechanical Properties

Components made up of duraluminum withstands high loads under repeated loading. Duralumin has both: high strength and excellent fatigue resistance. These properties are further enhanced by age-hardening of this aluminum alloy.

Lightweight

Aluminum is among the lowest weight common metals. It has a density of just 2.78 g/cm³. It far less than copper and steels. It is almost half that of titanium. So, parts composed of duralumin have a high specific stiffness.

Good Machinability

Duralumin offers an excellent machinability in precipitation hardened state. It enables perfect drilling, boring and milling operations. Intricate shapes can be easily carved out of this dural materials. As a result, precision machining with tight tolerance can be expected. Machined parts give a really good surface finish.

Corrosion Protection

While duralumin has a better corrosion resistance than steels, it is still less than other aluminum alloys. So, commonly the following surface treatments are done for corrosion enhancement:

- Alclad cladding

- Anodizing

- Protective coatings

- Paints

Recyclable

Can Duralumin be Recycled in Manufacturing? Yes! It is100% recyclable. Aluminium Recycling consumes far less energy than primary extraction.

What Are Typical Grades of Duralumin?

The earliest versions of duralumin contain around 95% aluminum and 4% copper. But it was not a strictly regulated composition. A lot of variations existed in these Al-Cu alloys. So, duralumin metals got a broad spectrum of alloys. ASTM as well as other international standards have classified duralumin alloy grades. Some of these common 2000 series aluminum alloys are mentioned in the below table:

|

Alloy grades |

Alloying Elements |

Strength Level |

Key Features |

Common Applications |

|---|---|---|---|---|

|

2011 |

Cu, Bi, Pb |

Medium |

Excellent machinability |

CNC parts, fasteners |

|

2014 |

Cu, Mg, Mn |

High |

High strength and good fatigue resistance |

Forgings, wheels and aerospace components |

|

2017 |

Cu, Mg |

Medium-high |

Good strength and Formability |

Structural components |

|

2024 |

Cu, Mg, Mn |

Excellent |

Excellent fatigue strength |

Aircraft skins and aerospace structures |

|

2219 |

Cu |

High |

Retains strength at high or cryogenic temperatures. It is weldable |

Spacecraft and fuel tanks |

|

2618 |

Cu, Mg, Fe, Ni |

High |

Excellent high temperature stability |

Engine pistons and aerospace engines |

|

2117 |

Cu, Mg |

Medium |

Reliable aging behavior |

Aircraft rivets |

Among them, 2024, 2017, and 2014 aluminum alloys are the most common Duralumin grades, let us explore more details about them.

2024 Aluminum

As it can be seen from the above table 2024 aluminum alloy contains the highest percentage of magnesium. It promotes precipitation of S phases. Hence 2024 aluminum grade has a very high strength and fatigue resistance. It is highly suitable for aircraft skins and fatigue-loaded structures.

2017 Aluminum Alloy

The strength of 2017 Aluminum Alloy is lower than 2024 aluminum. But it has a better ductility and formability. Its precipitation behavior and ageing is also more predictable.

2014 Aluminum

The higher silicon content in this alloy promotes good castability and hot strength. Hence 2014 alloy garde is mainly preferred for forgings and thick sections. The chemical composition of the these common duralumin grades are given below:

|

Alloy |

Cu |

Mg |

Mn |

Si |

Fe |

Others |

Al |

|---|---|---|---|---|---|---|---|

|

2024 |

3.8-4.9 |

1.2-1.8 |

0.3-0.9 |

≤0.5 |

≤0.5 |

Zn, Ti (trace) |

Balance |

|

2017 |

3.5 -4.5 |

0.4- 0.8 |

0.4-1.0 |

0.2- 0.8 |

≤0.7 |

- |

Balance |

|

2014 |

3.9-5.0 |

0.2-0.8 |

0.4 -1.2 |

0.5-1.2 |

≤0.7 |

- |

Balance |

Duralumin vs Other Metals

Every metal has its own set of properties which mark its usefulness in different applications. Duralumin metals have their own unique properties. Drawing a comparison with other common metals such as steel, brass, and general aluminum alloys helps in identifying suitability for particular applications.

Duralumin vs Steel

Duralumin wins by a great deal in a strength to weight ratio comparison with steels. The yield strength duralumin is comparable to the common grades of steel in the order of 300-450MPa. However, the weight of duralumin is incredibly lower. Consequently, duralumin alloys saves a lot of energy in automobiles and aircrafts. On the other hand, the lower cost of steels make it a preferred material in bulk volume applications. Corrosion resistance of duralumin is significantly higher than all steels except for the stainless grades.

Is Brass Better than Duralumin?

Brass and duralumin have significantly different properties. While brass is heavier and ductile, duralumin is lighter and strong. Brasses are commonly used in piping, valves, fittings and decorative parts. Duralumin is mainly used in structural parts that have light weight requirements. In short, brass and duralumin are not mutually replaceable materials.

Duralumin vs Other Aluminum Alloy

- 6061 Aluminum: 6061 alloy has a considerably lower cost thanduralumin. 6061 offers better corrosion resistance, good weldability but lower strength than duralumin.

- 7075 Aluminum: 7075 alloy is one of the strongest among all of the aluminum alloys. Its UTS is more than that of duralumin. 7075 is mainly preferred for its high load bearing ability while 2000-series aluminum alloys are known for their fatigue resistance and fracture toughness.

The below table draws a comparison od duralumin with these common materials:

|

Material |

Density |

Relative strength |

Corrosion Resistance |

Key Aspects |

Applications |

|---|---|---|---|---|---|

|

Duralumin |

Low |

Very High |

Moderate |

High strength-to-weight ratio and good fatigue performance |

Aircraft structures, high-load parts |

|

Steel |

Very high |

Very high |

Grade dependent |

High stiffness, wear resistance and low cost |

Heavy machinery, tools, structures |

|

Brass |

Very High |

Low - medium |

Excellent |

Corrosion resistant and high formability |

Valves, fittings and electrical parts |

|

6061 aluminum |

Low |

Medium |

Very Good |

Weldable, versatile and cost-effective |

Frames, marine and general structures |

|

7075 Aluminum |

Low |

Very high |

Moderate |

Highest strength in all Al alloys |

Aerospace, highly stressed parts |

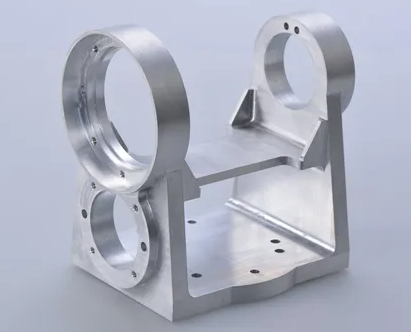

Can Duralumin be Machined?

Although the machining behavior of duralumin is a bit different than other aluminum series, it offers excellent machinability. Machined parts manufactured from duralumin possess high precision, good accuracy and a good machined surface finish.

Machinability of Duralumin

The precipitates in duralumin assist enhancing machinability. Its comparatively higher strength helps in producing clean chips. But a careful control of cutting parameters is required to prevent overheating and damage.

Suitable CNC Machining Techniques

- High Speed millingis used for carving out complex features like pocked and deep undercuts out of duralumin. It can be adopted to produce precise thin structures and aerospace parts. It needs a reduced cutting force that minimized workpiece deflection. Use of carbide tools further enhance machinability.

- CNC turningis usually employed for making cylindrical duralumin components. Bushings and shafts can be made using this technique.

- CNC drilling: Tuofa drilling technique and tapping produces precise holes and threaded features.

Challenges for Machining Duralumin

Although duralumin is an easy to machine alloys, but still certain challenges can pose difficulties, Some of them are stated below:

- Tool Wear

- Built-Up Edge

- Heat Buildup

- Chip Evacuation

What Is Duralumin Used for?

Owing to the exceptionally high strength to weight ratio, duralumin is mainly used in a lot of low weight applications. It offers the primary advantage of fuel efficiency in aerospace and automotive applications. The fatigue resistance that it offers is remarkably high making it more durable in cyclic loading applications.

Aerospace Industry

Aerospace industry is the primary beneficiary of duralumin components. Some of the components are mentioned below:

- Brackets

Brackets made up of duralumin have very good dimensional stability. It thus aids in critical support and join structural elements.

- Fittings

Hinge fittings, clevises, and linkages made up of duralumin are more reliable than other metals. Still it does not increase the weight of the aircraft.

- Precision Mounts

Precision mounts for avionics, instrumentation, and sensor housing get minimum deflection due to excellent stability under vibrations.

Automotive Parts

Fuel efficiency increases the performance of auto parts by many times. Duralumin promotes this fuel efficiency.

- Racing structural components

In racing cars, top speed and acceleration are the most critical indicators. Low weight of structural components helps in achieving just that.

- Lightweight connecting parts

Connecting parts like suspension arms, engine mounts, and linkages can be made with low weight without compromising strength.

Mechanical Equipment

- High-strength housings

Housings made up of duralumin maintains structural integrity under mechanical load. Bearing seats, seals, and mounting surfaces can be produced by duralumin.

- Precision support structures

Robotics frames, optical instrument mounts and precision fixtures can be produced from duralumin.

Does Duralumin Parts Need Surface Treatment?

Yes, duralumin requires surface treatment mainly for corrosion protection. There can be aesthetic reasons as well. In other aluminum alloys, a fully protective Al2O3 layer forms on the surface that protects against corrosion. However, as copper is added in a considerable quantity in duralumin, this natural surface layer does not cover the whole surface. At coating holidays, corrosion will start and form pits.

Common Surface Treatment for Duralumin Parts

Most commonly, duralumin parts are cladded with pure aluminum. This process is called ‘Alclad”. Anodizing, powder coating and painting are other surface treatment methods.

When Duralumin Parts Need Chrome Paint?

Chrome paint serves three purposes:

- corrosion protection

- aesthetic enhancement

- wear resistance

So, in environments where corrosive and wea attack is severe, chrome painting is preferred.

Conclusion

Duralumin is an alloy of aluminum having copper as its main alloying elements. Due to atomic sizes mismatch lattice distortion creates high strength in duralumin parts. It's density is far lower than other comparable strength materials. Its is highly machinable. As a result, it is widely used in aerospace, automotive and mechanical applications.

FAQ

Is duralumin stronger than steel?

Although duralumin has strength comparable to most common steel grades, but the are many steel alloys having a way higher yield strength than duralumin.

Is duralumin ferrous?

No, duralumin is a non-ferrous metal. It is a kind of aluminum alloy that possesses properties including high strength and low weight.

What is the most common 2000 series aluminum?

2024 aluminum is by far the most common 2000 series alloy.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What Is Oxygen Free Copper? A Complete Guide for You

What Is Oxygen Free Copper? A Complete Guide for You