What Is a Pipe Nipple? A Complete Guide to Types, Materials, and Machining

Aug 09,2025

Aug 09,2025

When you work with plumbing or piping, you often need to connect different parts. You might need to extend a pipe, connect a valve, or change the direction of flow. For these jobs, a small but essential component comes into play: the pipe nipple.

So, what is a pipe nipple?

Simply put, a pipe nipple is a short piece of pipe that has threads on one or both ends. It acts as a connector, allowing you to join two other pipes or fittings together. Think of it as a small bridge that creates a secure, leak-proof connection in a piping system.

This guide will explain everything you need to know. We will cover the different types of pipe nipples, the materials they are made from, and how they are manufactured. By the end, you will understand how to choose the right nipple for your project.

The Main Purpose of a Pipe Nipple

The primary job of a pipe nipple is to create a connection. Because they are short and threaded, they are incredibly versatile. Here are a few common ways people use them:

- Extending a Pipe: If a pipe is just a few inches too short, you can use a coupling and a pipe nipple to add the extra length you need.

- Connecting Fittings: Pipe nipples are perfect for connecting fittings like elbows, tees, or valves. For example, you can screw a nipple into a valve on one end and into an elbow on the other.

- Connecting to Equipment: Many machines, tanks, and pumps have threaded ports. A pipe nipple allows you to connect a pipe line directly to this equipment.

Without this simple connector, building and repairing piping systems would be much more difficult.

Exploring the Different Types of Pipe Nipples

Pipe nipples come in various shapes and designs. Each type serves a specific purpose. Understanding the differences will help you select the correct one for your needs.

1. Close Nipple (or Fully Threaded Nipple)

A close nipple has no unthreaded space in the middle. The entire length of the nipple is threaded. When you screw two female fittings onto a close nipple, they will touch, or come very close to touching. This creates the tightest possible connection between two fittings.

- Best Use: When you have very limited space and need two fittings to be as close as possible.

2. Barrel Nipple

This is the most common type of pipe nipple. It has a short, unthreaded section in the middle. The threads on each end are tapered. This unthreaded area makes it easier to grip the nipple with a pipe wrench without damaging the threads.

- Best Use: General-purpose connections in almost any plumbing or piping application.

3. Hexagonal Nipple

As the name suggests, a hexagonal nipple has a hexagon-shaped section in the middle. This hexagon serves the same purpose as the unthreaded area on a barrel nipple: it provides a surface for a wrench. However, because it is a hex shape, you can use a standard wrench or socket instead of a pipe wrench. This can prevent scratching or damaging the nipple.

- Best Use: Applications where you want a cleaner look or need to use a standard wrench for tightening. It's common in plumbing and hydraulic systems.

4. Weld Nipple

A weld nipple is different because it is not designed to screw in on both ends. One end is threaded, while the other end is plain. The plain end is designed to be welded directly onto a pipe, tank, or fitting. This creates a permanent, very strong connection.

- Best Use: High-pressure systems or applications where you need to add a threaded connection point to an unthreaded pipe or vessel.

5. Swage Nipple

A swage nipple is used to connect pipes of two different sizes. It is a reducing connector. For example, you could use a swage nipple to connect a 1-inch pipe to a 3/4-inch pipe. They can have different end connections, such as threaded on both ends, plain on both ends, or one of each.

- Best Use: When you need to increase or decrease the pipe diameter in a system.

6. Grooved Nipple

This type has grooves near the ends instead of, or in addition to, threads. These grooves are used with grooved couplings (like a Victaulic coupling) to create a flexible yet secure connection. This system is often faster to assemble and disassemble than threaded systems.

- Best Use: Fire sprinkler systems, industrial applications, and situations where some pipe movement or vibration is expected.

Common Materials for Pipe Nipples

The material of a pipe nipple is critical. It determines the nipple's strength, corrosion resistance, and what kinds of fluids it can handle. Choosing the wrong material can lead to leaks, contamination, or system failure.

Carbon Steel

Carbon steel is strong, durable, and relatively inexpensive. It is the most common material for pipe nipples used in industrial applications. Black steel nipples (a type of carbon steel) are often used for gas lines and sprinkler systems.

- Pros: High strength, affordable.

- Cons: Prone to rust if not protected.

Galvanized Steel

Galvanized steel is carbon steel that has been coated with a layer of zinc. This zinc coating protects the steel from rust and corrosion. Galvanized nipples are very common in water supply lines and outdoor applications.

- Pros: Good corrosion resistance, durable.

- Cons: Not suitable for gas lines (zinc can flake off and clog equipment).

Stainless Steel

Stainless steel contains chromium, which gives it excellent resistance to rust and corrosion. It is also very strong and can handle high temperatures. This makes it ideal for food and beverage processing, chemical plants, and marine environments.

- Pros: Excellent corrosion resistance, hygienic, handles high temperatures.

- Cons: More expensive than carbon steel.

Brass

Brass is an alloy of copper and zinc. It is highly resistant to corrosion and is a good conductor of heat. Brass nipples are a top choice for drinking water plumbing because they do not release harmful chemicals and resist corrosion from water.

- Pros: Excellent for water, good corrosion resistance.

- Cons: Not as strong as steel.

PVC (Polyvinyl Chloride)

PVC is a type of plastic. PVC nipples are lightweight, cheap, and completely immune to rust. They are used in low-pressure, low-temperature water applications, such as irrigation, drainage, and home plumbing (DWV - Drain, Waste, Vent).

- Pros: Inexpensive, lightweight, will never corrode.

- Cons: Not strong, cannot handle hot water or high pressure.

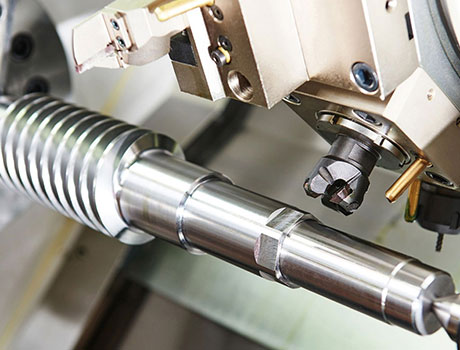

The Manufacturing Process: How Are Pipe Nipples Machined?

Understanding how a pipe nipple is made gives you an appreciation for its quality. The process requires precision to ensure the threads are correct and the connections are safe.

- Cutting the Pipe: The process starts with a long piece of pipe of the desired material (e.g., carbon steel, stainless steel). An automated saw cuts the pipe into short, precise lengths called "blanks." The length of the blank depends on the final size of the nipple.

- Chamfering the Ends: The cut ends of the blank are often sharp and rough. A machine grinds the inside and outside edges of each end. This process, called chamfering, creates a beveled edge. A beveled edge makes it much easier to start threading the nipple into a fitting.

- Threading: This is the most critical step. The blank is placed in a threading machine. Cutting dies rotate around the ends of the pipe, cutting grooves to create the threads. The most common thread type in North America is NPT (National Pipe Thread). NPT threads are tapered, which means they get slightly wider toward the end. This taper helps create a tight seal when the nipple is tightened into a fitting.

- Finishing and Cleaning: After threading, the nipples may have metal shavings or cutting oil on them. They are cleaned and deburred to remove any sharp edges. For galvanized nipples, this is the stage where they are dipped in molten zinc.

- Quality Control and Inspection: Each nipple is inspected. Inspectors check the thread quality, length, and overall finish. They use special gauges to ensure the threads meet industry standards (like ASME B1.20.1 for NPT threads). This final check guarantees the nipple will create a secure, leak-free connection.

Surface Finish of Pipe Nipple in Various Situations

The surface finish of a pipe nipple is more than just about its appearance. The finish provides critical protection against corrosion and makes the nipple suitable for specific jobs. Understanding the finish helps you choose a product that will last.

Black Finish

A black finish is the most basic surface for carbon steel nipples. The dark color comes from a thin layer of iron oxide left on the surface during the manufacturing process. This finish offers very minimal protection against rust.

- Situations: This is the standard for natural gas and propane lines. It is also common in oil lines and fire sprinkler systems. You should not use black steel nipples for drinking water, as they will rust and contaminate the water.

Hot-Dip Galvanized Finish

To create this finish, a steel nipple is dipped into a bath of molten zinc. The zinc creates a thick, durable, and protective coating over the entire surface. This coating is excellent at preventing rust.

- Situations: This is the go-to finish for plumbing that carries drinking water. It is also ideal for any outdoor piping, compressed air lines, and general industrial use where moisture is present.

Chrome Plated Finish

For a chrome plated finish, a thin layer of chromium is applied over a base material, which is often brass or steel. This process creates a bright, shiny, and highly reflective surface.

- Situations: You will find chrome plated nipples in applications where appearance is very important. This includes exposed plumbing under sinks, for showerheads, and other visible fixtures in bathrooms and kitchens. The finish is not only decorative but also easy to clean and resists water spots.

Unfinished Stainless Steel

Stainless steel nipples are unique because they typically do not have an external coating or finish. The material itself, with its high chromium content, is naturally resistant to rust and corrosion.

- Situations: Because it is so clean and does not need a coating that could flake off, unfinished stainless steel is required in sensitive environments. This includes food and beverage processing, pharmaceutical manufacturing, chemical plants, and marine applications.

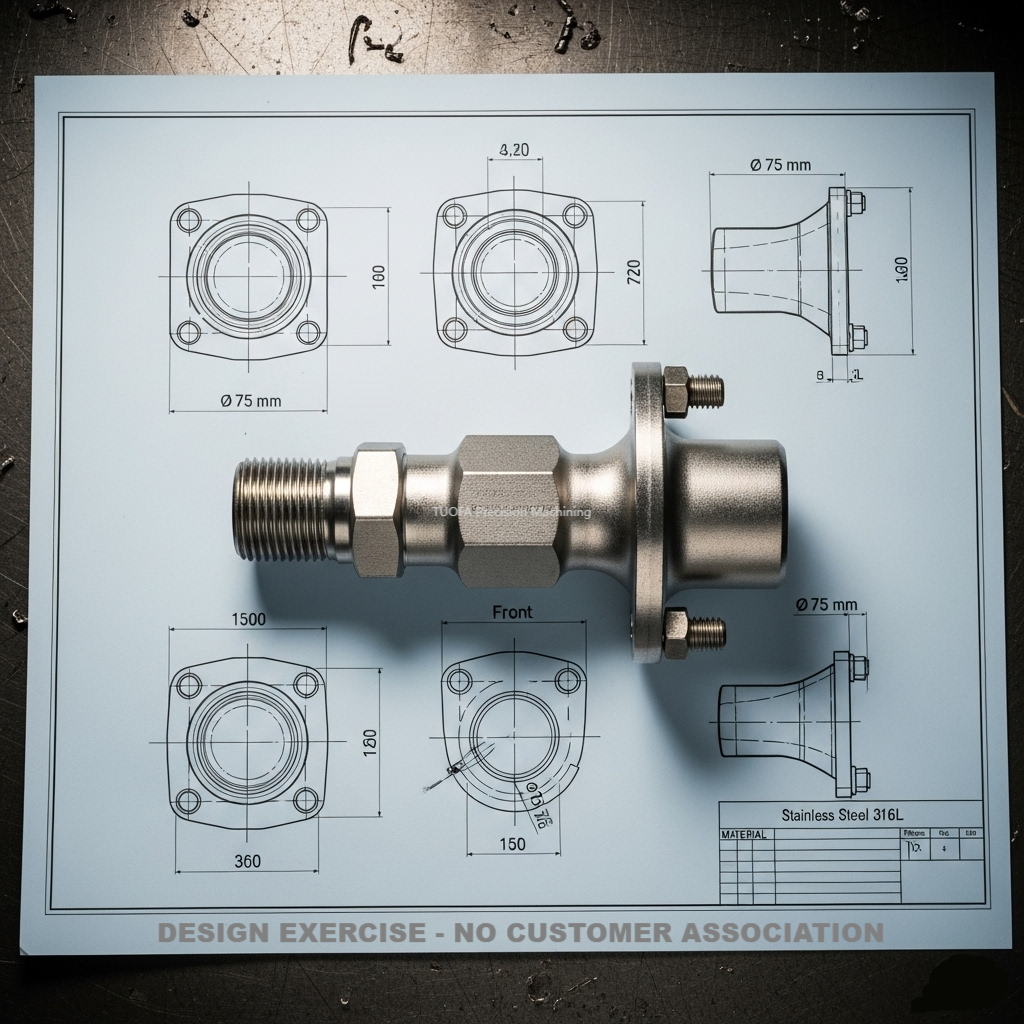

How to Custom-Make Your Pipe Nipple?

Sometimes, a standard, off-the-shelf pipe nipple won't work for a specific job. The length might be wrong, or you might need a unique combination of threads and materials. In these cases, you can order custom-made pipe nipples from a trustworthy supplier. Here is the key information you need to provide to a manufacturer:

- Dimensions: Be very precise.

- Diameter: The nominal pipe size (e.g., 3/4", 2").

- Length: The exact overall length from end to end.

- Wall Thickness: The pipe schedule (e.g., Schedule 40 for standard pressure, Schedule 80 for higher pressure).

- Material: Specify the exact grade of material. For example, instead of just "stainless steel," specify "Stainless Steel 316L" or "Carbon Steel A106."

- Thread Specifications:

- Thread Type: NPT (American standard), BSPT (British standard), or another type.

- Thread Ends: Do you need threads on both ends, or just one? Do you need a plain end or a beveled end for welding?

- Thread Direction: Most threads are right-handed, but specify if you require a left-handed thread for a special application.

- Nipple Type and Finish:

- Specify if you need a barrel nipple, a hex nipple, or a more complex swage nipple.

- Define the required surface finish, such as hot-dip galvanized or black.

By providing this detailed information to a reputable pipe fitting manufacturer or machine shop, such as TUOFA precision machining shop, you can get a pipe nipple that perfectly fits your requirements. And don't forget to mention the quantity you will require.

Conclusion

A pipe nipple may be a small component, but it plays a huge role in the reliability and safety of any piping system. It is more than just a short piece of threaded pipe; it is a precisely engineered connector.

By understanding the basic answer to "what is a pipe nipple" and learning the different types, materials, and surface finishes, you can work more effectively. Whether you are a professional plumber, an industrial maintenance technician, or a DIY homeowner, choosing the right nipple ensures your connections are strong, durable, and leak-free for years to come.

FAQs

What is the difference between a pipe nipple and a coupling?

A pipe nipple has external (male) threads and is essentially a short piece of pipe. It is used to connect two fittings with internal (female) threads. A coupling, on the other hand, is a short fitting with internal (female) threads on both ends, used to connect two pipes or two nipples.

Why can't I use a galvanized nipple for a gas line?

The zinc coating on a galvanized nipple can flake off over time. These small zinc flakes can travel down the gas line and clog the small openings in appliance regulators or valves. This can cause the appliance to malfunction. For this reason, black steel (carbon steel) is the required standard for natural gas and propane.

How do I make a threaded pipe connection leak-proof?

To ensure a seal, you must use a thread sealant. There are two main types: PTFE tape (also called Teflon tape) and pipe thread sealant paste (pipe dope). You apply the sealant to the male threads of the nipple before screwing it into the fitting. The sealant fills any tiny gaps in the threads, preventing leaks.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

O-Rings and Seals: Guide to Types and Custom Selection

O-Rings and Seals: Guide to Types and Custom Selection