O-Rings and Seals: Guide to Types and Custom Selection

Aug 15,2025

Aug 15,2025

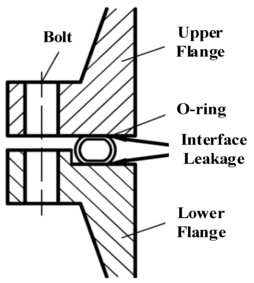

You must have seen O-rings or O’rings seals somewhere and you are thinking what is this actually? These are sealing rings that are used commonly in many industries. O-rings are gasket shaped rings and have a circular cross-section. These designs create a seal and prevent liquid or air from leaking. More information about these rings is discussed in detail in this article.

What Is O-Rings and Seals?

O-rings and seals prevent leakage of fluids or gases. They also remove contaminants between two or more mating surfaces. They are required to be in circular, or loop-shaped elastomeric rings. Seal is a generic term used for various types of sealing devices other than O-ring seal, like lip or mechanical seals, and gaskets.

Functions of the O-Rings and Seals

The functions of O-ring seals are:

- Prevent leakage from a system for operational integrity

- Acts as a barrier for contaminant exclusion

- Maintain pressure inside the system

- Separate different liquids inside the system and prevent their mixing

- Provide minor vibration dampening to reduce noise

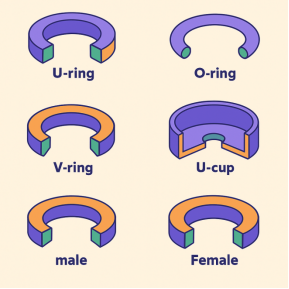

O-Rings and Seals by Shapes: Standard & Custom

O-rings and seals have many shapes and sizes such as hollow, D-rings, X-rings or quad rings. These are categorized on their functionality and performance benefits.

Standard Round Shapes (AS568 / ISO 3601)

The dimensions of these circular shaped seals are defined with AS568 and ISO 3601 standards. They have tight dimensional tolerances of ±0.08 mm tolerance and are used in static and dynamic sealing applications.

Square and X-Ring Profiles

They have square cross-sections and are designed to fit in O-rings grooves. They are used size-for-size as replacements of O-ring seal in existing applications. X-rings are 4-lobed cross-section and have more robust sealing surface.

Hollow, D-Ring, and Quad-Ring Variants

Hollow shaped rings have tubular cross-section and are used for lightweight or flexible seal requirements. D-rings are used in certain types of machinery. Quad-shape rings are same as X-rings and have better sealing performance in dynamic applications.

O-Rings and Seal Types by Materials and Property

O-rings are seals are classified on materials, chemical stability, operating temperature and their applications. Some of the most common materials of Orings and seals are as:

1. Nitrile O-Rings and Seals

It is synthetic rubber O rings, NBR, made of acrylonitrile and butadiene. The working temperature is -30 to 120°C and has good resistance to oils and fuels. It is mostly used for automotive and mechanical seals etc.

2.EPDM and Silicone Seals

The EPDM and Silicone O-rings have working temperatures up to 200°C or higher. They have good resistance to water, steam, and some chemicals and higher flexibility. Common applications are medical, food processing, and automotive industries.

3.Fluorocarbon (Viton / FKM) Seals

Fluorocarbon elastomers or Viton (FKM) have working temperatures ranging up to 230°C. They also have high chemical resistance to oils, solvents, and acids. Common applications for these O-rings are aircraft fuel systems.

4.PTFE, FFKM, and Metal O-Rings

PTFE, FFKM and Metal O-rings have working temperatures of -200 to 250°C.Thesee are suitable for very high temperatures and have high chemical resistance too. These are used in chemical and pharmaceutical industries and for ultra-high vacuum systems.

Quick Reference Table: Temperature, Chemistry, Cost

A reference table for all the types of O-rings and seal mentioned above are:

|

Features |

Nitrile |

EPDM and Silicone O-rings |

Fluorocarbon |

PTFE, FFKM, and Metal O-Rings |

|

Temperature |

-30°C to 121°C |

-73°C to 200°C |

-26°C to 230°C |

200 to 250°C |

|

Chemistry |

Good for oils, water, and hydraulic oils |

water, steam, and chemicals |

oils, hydrocarbons, and acids |

Good most chemicals. |

|

Cost |

Cheap |

Cheap |

Expensive |

Expensive |

What is The Difference Between Type 1 and Type 2 O-Rings?

Type 1 and Type 2 O-rings are different in type of elastomers. They have different properties like chemical and temperature resistances and their performances.

How to Define Type 1 and 2 O-Rings

Type 1 are basic synthetic rubber o rings like Nitrile, Neoprene and EPDM. Type 2 are special elastomers like Viton, Flurosilicone and silicone O-rings. Type 1 are general-purpose sealing and are cheap and Type 2 are used for specialized applications like high temperature, harsh chemicals and specific solvents applications.

Main Differences of Type 1 and 2 O-Rings

The main difference between Type 1 and Type 2 O-rings are as:

|

Features |

Type 1 O-Rings |

Type 2 O-Rings |

|

Chemical resistance |

Less resistance |

Higher resistance to harsh chemicals |

|

Temperature |

Low working temperature |

High up to 300°C |

|

Cost |

Cheap and readily available |

Expensive |

|

Performance |

Normal performance |

better sealing performance |

Static vs Dynamic O-Rings and Seals

These O-rings and seals have different purposes and applications based on if the sealing surfaces are stationary or in motion.

Design Purposes

Static seals have simple groove geometry and provide more space to compress and create tight fit. Their groove dimensions are less critical and there is no movement to consider.

While the dynamic seals have precise groove geometry to manage the sealing movement. Factors like surface finish, chamfers, and groove depth are important to minimize friction and preventing seal damage to the seal.

Static vs. Dynamic Applications

Static O-rings and seals are used in sealing a gasket between two engine blocks or sealing a pipe fitting. Dynamic sealing is used in hydraulic cylinder, a pump shaft, or a rotary union.

How to Decide Static or Dynamic Seals

There are few things to consider in their selection:

- Identify the motion like relative or static.

- Determine the applications requirements like pressure, temperature, and fluid compatibility.

- Choose material that can survive operating conditions.

- Select suitable groove design.

O-Ring Types by Industries and Standards

O-rings are versatile and used in many industries to prevent leakage. These are made of materials standards like ISO-23936 that can survive vacuum conditions and prevent contamination.

Aerospace Seals

O-rings are important parts in aircraft engines, hydraulics, and other systems. They are normally made according to AS (Aerospace Standard) and MS (Military Standard) specifications.

Food & Pharma Seals

O-rings made for food and pharma industries must be according to FDA-compliant. And this must be safe for use with food and pharmaceuticals.

Oil & Gas / Petrochemical Seals

O-rings made for these applications should withstand chemical and hydrocarbon exposure. The temperatures and pressures bearing requirements must follow ISO 23936 standard.

Semiconductor & Vacuum Seals

For these applications, they must be made from material that can maintain a vacuum seal and prevent contamination.

Key Factors for Custom O-Ring Selection

Custom O-rings are used when standard sizes or materials cannot be used in specific application. There are some factors to consider while making custom O-rings.

Chemical Compatibility Solutions

They must have fluid and gas compatibility to prevent swelling and leakage. Choose suitable material because each material has its own resistance level such as Viton has high resistance to chemical and temperatures.

Temperature & Pressure Limits

O-rings must have high operating temperatures and pressure range. Different levels of temperatures can affect sealing performance and inadequate pressure can cause extrusion or failure of rings.

Precision Sizing & Compliance

O-rings must have optimal groove fit and sealing performance. Groove size and dimensions must be compatible with O-ring's cross-sectional diameter. And most importantly static and dynamic applications require different designs and materials.

Benefits of Custom O-Rings and Seals

Custom O-rings and seals have many advantages over standard designs. They have better sealing performance, higher durability and system efficiency. They also have less maintenance cost and better product reliability.

Conclusion

O-rings and seals are an important part in preventing leakage in different areas. Selection of right type is based on the industrial applications requirements or type of project needs. Common materials of O-rings and seals are Nitrile, silicone O-rings, Viton and EPDM. They all offer different levels of chemical, temperature and pressure other than that, standards, metric, and sealing applications like dynamic or static also decide the type of seal selection.

Are you ready to find the perfect O-ring or seal for your work? Contact TUOFA today for expert advice and custom solutions.

FAQs

What's the difference between Viton and Nitrile O-rings?

Viton has higher temperature and chemical resistance, and Nitrile is cheaper and more abrasion resistant.

Can a Square O-Ring Replace a Round One?

Yes, square O-rings can be used in many static applications as a replacement for a round O-ring seal.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What Is Progress Stamping? How It Work?

What Is Progress Stamping? How It Work?