Renewable CNC Machined Parts: Complete Guide to Green Precision

Jul 11,2025

Jul 11,2025

Renewable and sustainable energy systems require precision machined part for higher efficiency. For example, around 40% of new wind turbine installations rely on precision-machined parts. CNC machined parts in renewable industry have higher accuracy which increases the performance and lifespan of renewable energy technologies. This article highlights how CNC machining drives a greener future through precision in renewable energy production.

CNC Machining in Renewable Energy-Overview

CNC is Computer Numerical Control. It is defined as a manufacturing process which has pre-programmed computer software to precisely control machine tool movements. This creates complex, high-quality parts with tight tolerances, crucial to renewable energy applications ;for their optimal efficiency and performance in harsh environments.

CNC Machining in Solar Power System

Parts of Solar power system such as panel frames, mounting structures, and concentrators are normally made from CNC machining to get high precision for optimal light capture and energy conversion in green energy application.

CNC Machining in Wind Power System

CNC machining for wind turbine blades, nacelles, and hub components efficient aerodynamic performance and structural integrity.

CNC Machining in Hydropower System

Turbine parts like penstocks, and other critical hydropower system parts are manufactured by CNC machining to have high efficiency in water flow and energy generation.

CNC Machining in Conventional Generators and Turbines

Turbine blades, generators housing and other traditional power generation are also manufactured by CNC machining to have high precision, optimal efficiency and reliability.

Core Advantages of CNC for Green Components

CNC machining offers many advantages in producing green energy components production. Some of them are:

Sub-0.01 mm Precision for Energy Efficiency

The core strength of green precision lies in achieving extremely tight tolerances (sub-0.01 mm). It also reduces waste and increases production speed and repeatability. These factors are essential to optimize the performance and service life of parts in energy-efficient systems such as wind turbines.

Rapid Prototyping to Scale-Up Speed

CNC machining allows Rapid prototyping and faster transformation from CAD design to testing. The key features are material flexibility, cost-effectiveness and speed precision which make the quick iteration and design validation easier.

Lower Scrap Rates than Cast/Forge

In general, CNC machining has lower scrap rates than traditional manufacturing methods. They precisely remove material and minimize waste in the context of hydro runner vanes.

CNC Machined Parts for Renewable Energy Components

The levelized cost of energy (LCOE) is better in CNC machined due to higher efficiency, service life and reducing maintenance of critical components. The three "hero" parts that have this potential are high-precision turbine blades, fasteners for turbines and customized heat exchangers. They can reduce costs substantially over the lifetime of the renewable energy system.

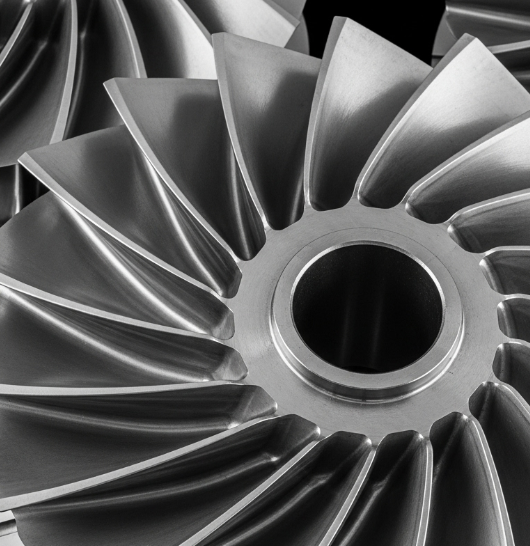

5-Axis Machined Impellers for Micro-Turbines

5-axis machines create highly complex parts like curved blades and intricate passages found in micro-turbine impellers. They are normally difficult to machine with traditional 3-axis methods. 5-axis machining offers high precision and accuracy with minimal vibration in impeller blades.

Aluminum Heat-Sink Housings for Inverters

Aluminum heat-sink housings with machined fins have significant reduction in inverter temperature. The surface area is increased by the fins for heat dissipation through convection which lowers the operating temperature of the inverter and prevents overheating.

Titanium Fasteners for Offshore Turbines

Titanium has inherent corrosion resistance for marine environment; and CNC machining further makes it durable for these conditions. CNC machining for titanium fasteners allows to create parts more precisely and complex geometries that are required by turbine design.

Precision Machined Parts List

Precision machined parts play an important role in the working of wind, solar and hydro power plants.

Machined Parts in Wind Power

Machine parts in wind power have higher reliability and efficiency of wind energy generation.

Machined Parts in Solar Power

CNC machining produced durable and lightweight structures for solar systems and ensured reliable solar generation.

Machined Parts in Hydro Power

Hydro power parts heavily rely on CNC machining because it is almost impossible to make parts with traditional methods.

|

Power systems |

Machined parts |

|

Wind power |

Shaft, bearing, gears, hub parts, yaw system parts, blade pitch parts, nacelle parts |

|

Solar power |

Mounting frames, inverter housing, tracking system part |

|

Hydro power |

Turbine shaft, runner parts, guide vanes, bearing housings |

New Energy CNC Machining Materials Selections

Right material selection is crucial for new energy CNC machining for long life, high performance and low price. Common materials are as:

Recycled 6061 & 6082 Aluminum

These are excellent choices for CNC machining parts in renewable energy applications. 6061 has high strength, corrosion resistance, and machinability while 6082 is stronger and has structural integrity. They are also recyclable and have less environmental impact.

Duplex Stainless Steel

Duplex stainless steel is strong and corrosion resistance alloy and ideal for offshore wave-energy flange plates due to their unique microstructure and properties. It has higher strength, toughness, and excellent localized and general corrosion resistances in chloride-rich environments.

Bio-Based Plastics

Bio-based plastics like PLA, ABS, polycarbonate, and nylon are ideal for lightweight sensor housings in new energy applications. Material selection of engineering plastic depends on required strength, durability, environmental conditions, and desired sustainability.

New Materials

Advancement in materials for new energy applications includes composites (CFRP, GFRP), advanced metals (Inconel), and smart materials (piezoelectric materials).

Advanced CNC Processes for Complex Geometry

Some of the advanced CNC processes like 5-axis milling, Turn-Mill Swiss machining, and hybrid additive manufacturing are essential for producing complex parts in renewable energy.

5-Axis Milling of Curved Blade Roots

5axis milling for wind turbine blade roots allows for optimal aerodynamic performance and structural integrity by precise machining of curved surfaces. It also takes less cycle time and has a better surface finish.

Turn-Mill Swiss for Long Stainless Shafts

Hydro turbine shafts made of stainless steel by turn-mill Swiss has higher precision and dimensional accuracy over their length. Swiss machining produced parts with tight tolerance with minimal waste and maximum efficiency.

Hybrid Additive + CNC for Hollow Cooling Channels

Hybrid additive manufacturing with CNC machining creates part like cooling channels with optimal thermal performance and lightweight. They have enhanced thermal management provided by internal cooling channels.

Surface Finishes in Renewable CNC Machining Parts

Different types of surface finishes are used in renewable energy CNC machined parts to increase durability and performance. Some of them are as:

Hard Anodize

A thick, hard and durable oxide layer is created in hard anodizing of aluminum parts. This makes them ideal for high-wear applications like solar tracker parts. This process also offers customizable colors with a matte, darker appearance.

HVOF Carbide Spray

HVOF coatings are applied to parts like hydro wear rings to improve wear and corrosion resistance in harsh environments. Carbide particles are sprayed at high velocity in this process to create a dense, protective layer.

Ceramic PVD

Ceramic PVD is used for fuel-cell plates to provide hard, durable, and corrosion-resistant coatings. A thin film of ceramic layer is deposited to protect the surface which further improves the wear resistance and lifespan of parts.

Planning Your Custom Renewable CNC Machining Parts Projects

The most important step in planning your CNC machined parts for renewable energy components is to find a reliable supplier. But do not worry, we will guide you in this step.

How to Find a Proper Manufacturer?

It involves a range of things to find a supplier with a proven track record, advanced equipment, and a strong engineering team for CNC machined parts for renewable energy components. Here is the checklist for your ease:

|

✅ |

Category |

Checklist Criteria |

|

☐ |

Capabilities |

Handles required processes |

|

☐ |

Works with your materials |

|

|

☐ |

Industry experience (renewable energy) |

|

|

☐ |

Uses modern CNC machines & CAD/CAM software |

|

|

☐ |

Quality Assurance |

Holds ISO 9001 or similar certification |

|

☐ |

In-house inspection |

|

|

☐ |

Full material/component traceability |

|

|

☐ |

Engineering Support |

prototyping & DFM advice |

|

☐ |

Design & engineering support |

|

|

☐ |

Production & Scale |

prototype to mass production |

|

☐ |

Meets lead time requirements |

|

|

☐ |

Communication |

Willing to sign NDA |

|

☐ |

Responsive & transparent in updates |

|

|

☐ |

Pricing & Cost |

Competitive pricing, clear cost breakdown |

|

☐ |

Reputation |

Positive reviews or case studies |

TUOFA Custom Renewable CNC Machining Parts

TUOFA has all of the qualities of a great supplier and offers a variety of advanced CNC machining services for your renewable energy project.

Benefits of Choosing TUOFA CNC Machining

TUOFA is a one-step solution for all your needs. TUOFA has a wide range of capabilities with advanced technologies for CNC machined parts in renewable industry. We have a strong engineering team to design, prototype and quality control with a customer focused approach. We are committed to quality, precision, and timely delivery.

Conclusion

CNC machined parts in renewable industry impart high precision, durability and efficiency in solar, wind, and hydropower systems. The future of renewable energy relies on the advancements in solar and wind technologies, growth of energy storage, and development of green energy hydrogen. These all rely on precision engineering provided by CNC machining.

FAQs

How can CNC machines be used for greener manufacturing?

CNC machines can be used by minimizing material waste and environmental impact and by optimizing energy consumption.

What’s the smallest batch size I can order for renewable CNC parts?

Smallest batch size means usually between 10-1000 pieces.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Precision vs Accuracy in CNC Machining: A Practical Engineer’s Guide

Precision vs Accuracy in CNC Machining: A Practical Engineer’s Guide