Plastic Components in Cars: 7 Most Common Types

Sep 26,2025

Sep 26,2025

Automobile manufacturers are always in a quest to bring a high level of fuel efficiency and a good mileage. The mass of an automobile has a direct relation with the fuel efficiency. Plastic components in cars greatly help in achieving the goal of reducing mass. Plastic in cars also gives other benefits like flexibility in design, lower cost of parts, insulation and aesthetics. Let’s find out more about it!

What Are Plastic Components in Cars?

Plastics in cars can be found everywhere. Owing to the tremendous benefits of plastics a lot of functional and cosmetic parts are made out of it. Let’s see if BMW have plastic parts? Yes! Plastic components can be found allover a BMW. The smart, cozy and aesthetically pleasing interiors all made up of plastics. The wiring systems, electrical housing even many underhood car engine parts are made up of plastics. Even the BMW logo that is displayed on the front is made up of plastics.

What Are Cars Made out of?

Cars are actually an assembly of many different auto parts that work in synchronization. Each auto part is made up of a separate material based on the required functional use. The below table highlights some of the auto parts and their materials:

|

Area |

Materials |

Examples |

|

Exterior |

Steel, Aluminum, Plastics, Composites |

Bumpers, doors, hoods, grilles |

|

Interior |

Plastics, Foam, Textiles, Leather |

Dashboard, seats, door panels |

|

Underhood |

Plastics, Aluminum, Steel |

Engine cover, intake, reservoirs |

|

Chassis |

Steel, Aluminum, Composites |

Frame, suspension, crash beams |

|

Electrical |

Plastics, Copper, Aluminum |

Wiring, connectors, fuse boxes |

|

Glass and Lighting |

Glass, Polycarbonate |

Windshield, headlamps, taillights |

|

Wheels & Tires |

Rubber, Steel, Aluminum |

Tires, rims, hubcaps |

|

Underbody |

Plastics, Composites |

Skid plates, aero shields, liners |

Definition and Scope

Auto parts made up of thermoplastics or thermosets are referred to as plastic components in cars. These components utilize distinct manufacturing methods like injection molding, blow forming, extrusion or weaving. Commonly found examples are dashboards, seats, trims, covers, housings, lights, and so on.

Where Plastics Are Found on a Vehicle

The below table highlights some areas where common plastics are found:

|

Plastic |

Main Uses in Cars |

|

PP (Polypropylene) |

Bumpers, dashboards, door panels |

|

ABS (Acrylonitrile Butadiene Styrene) |

Trims, consoles, grilles |

|

PC (Polycarbonate) |

Headlamps, sunroofs, light covers |

|

PA / Nylon (Polyamide) |

Engine covers, manifolds, gears |

|

PU (Polyurethane) |

Seat foam, insulation, steering wheels |

|

PVC (Polyvinyl Chloride) |

Wire insulation, seals, trims |

|

PMMA (Acrylic) |

Taillights, display panels, windows |

|

PBT (Polybutylene Terephthalate) |

Fuse boxes, connectors, housings |

|

PE (Polyethylene) |

Fuel tanks, splash guards, reservoirs |

|

CFRP/GFRP (Fiber Composites) |

Body panels, roofs, spoilers |

How Many Plastic Parts Are in a Car?

Around 100-150kgs of different auto parts plastics are used in a normal car.

Plastics are used in exterior, interior, underhood, electrical and underbody.

Why Are Plastics Used in Car Manufacturing?

Car parts manufacturing is incomplete without plastics. The properties of plastics are unparalleled for many auto parts. Plastic in cars reduces weight, improves safety and beautifies designs. That’s not all. There are numerous other benefits of using plastic in cars. Plastic auto parts are gaining traction among OEM in NEVs/EVs. Let’s find more about “why is plastic used in cars?”

Fuel Efficiency

Plastic components in cars help in saving a lot of fuel. Plastics are around 50% lighter than metals. This saving in weight needs a smaller drag force. Hence the car engine needs to work less for travelling a specific distance.

Flexible Design Integration

Injection molding allows intricate shapes to be made out of plastics. Intricate curves and textures produce aesthetically pleasing designs. Plastics auto parts also have an ease of assembling. Modular components can be integrated with ease.

Make Vehicles Safer

Many safety components like airbags, bumpers and seat belts are made out of plastics. They have the ability to absorb impact while demonstrating durability. In electrical components plastics provide insulation that prevent short circuiting.

OEM Plastic Parts in NEVs/EVs

Neighborhood Electric Vehicles (NEV)s and Electric Vehicles (EV)s are the future of automobile industry. Due to discouragement of fossil fuels and imposition of carbon tax in many countries, EVs are gaining traction. Currently, the biggest challenge for EV manufacturers is to enhance the mileage. By offsetting the weight of heavy battery packs with lightweight plastic car parts, mileage can be improved. Plastic components in EVs help in improving design features. Intricate curvatures can be incorporated in plastic parts to improve aerodynamics.

If you’re an EV manufacturer feel free to contact us immediately for ordering custom made NEV/EV parts.

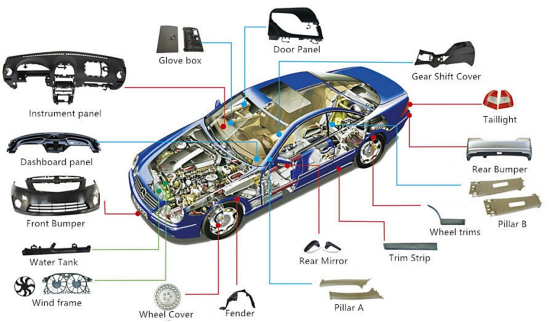

List of Plastic Components in a Car by System

Automobiles rely heavily on plastic components. By far plastic is the most versatile class of material. It is used in structural, optical, lighting, electrical and even the safety features of a car. In this section, plastic parts are listed based on their location and functionality.

Exterior Plastic Parts

- Bumpers

- Grilles

- Fender liners

- Lamp lenses

- CNC machined partslike bezels, trims and logo badges

Interior Trim Parts

The aesthetically appealing interior car trim design is the benevolence of plastic car parts. Here is a list:

- Dashboards

- Consoles

- Door panels

- Pillars

- CNC machined partslike gear shifter trims, HVAC bezels and infotainment housings.

Underhood and Thermal Management

- Air intake

- Engine covers

- Radiator end tanks

- PA6/PA66-GF for air intake.

- Manifolds

Electrical and Lighting

- Connectors

- Housings

- Headlamp lenses

- PBT/PET for connectors;

Underbody and Aero

- Diffusers

- Rocker covers

- Sheilds

- Wheel Arch liners

7 Common Automotive Plastics and Properties

Plastics come in a different of compositions. Each type of polymer has a set of properties that make it suitable for a specific application. As our title “Plastic Components in Cars: 7 Most Common Types” suggests we’ll be discussing seven most common types of plastic materials that are used in cars.

1.Polypropylene (PP) Parts in Cars

Polypropylene is the most extensively used material in cars. Polypropylene car parts are lightweight, resistant to chemicals, shock absorbing and easy to manufacture. Polypropylene car parts are used wheel-arch liners bumpers, dashboards, door panels and battery cases.

2.ABS and PC-ABS Parts in Cars

ABS and poly carbonate blended ABS gives a very nice surface finish. ABS and PC-ABD can be easily plated to the desired finish. As a result, these plastic components are used in car trim design. Examples include interior trim, center consoles, grilles and mirror housings.

3.PVC Parts in Cars

What is the PVC material in cars?

Poly Vinyl Chloride is a durable, flexible and a flame-retardant material. In cars, plastic components made up of PVC are used in wire insulation, seals, underbody coatings and even the seat upholstery.

4.HDPE and LDPE Parts in Cars

Both HDPE and LDPE are Polyethylenes. HDPE is high density polyethylene. It is stiff and strong. LDPE is low density polyethylene and it is soft and flexible. HDPE is mainly used in fuel tanks and fluid reservoirs, while LDPE is used in floor mats, insulation films, protective sheets.

5.Polyamide (Nylon PA6/PA66) Parts in Cars

Polyamides are high performance and most widely used engineering plastics. Polyamides can withstand high temperature and impact resistance. PA6 nylon is slightly lower in cost and PA66 is a bit expensive. These polyamides are mainly used in air intake manifolds, engine covers, gears, bearings and fuel system parts.

6.Polycarbonate (PC) and PMMA (Acrylic) Parts in Cars

PC and PMMA are clear and transparent plastics. These are mainly used in car lights, sunroofs, windows and interior light covers.

7.PBT and PET Parts in Cars

PBT and PET are specialized engineering plastics used mainly in electrical application. In automobile, electrical/connector housings, sensor bodies and fuse boxes are made out of PBT or PET.

New Types of Plastics in Cars

With the evolution of automobile industry and the introduction of NEV/EV, advanced plastics are being used. As an example, CFRP has a superior strength and impact resistance. Hence CRFP helps in reducing weight. Another example is that of smart plastics that can conduct electricity. Research is ongoing for its application in the EV industry.

Plastics vs Metals and Composites

Material selection is often a very critical process in car components manufacturing. The overall performance and lifetime of a car depend on the materials are used. In older days, most of the auto parts were made out of metals. But now with innovation in the plastics industry, the trend is shifting towards plastics. Now, even Aluminum which has a very low density is being replaced with plastics. Designers are weighing the cost and benefits in a plastic vs aluminum car parts comparison.

Engineering Plastic vs. Aluminum in Car Parts

Aluminum is gradually being replaced with high performance plastics due to lower weight, lower cost, high precision and high durability. Nevertheless, Aluminum still stands above plastics in key areas like strength, recyclability, fatigue resistance and weldability. As an example, PA66 plastic is although very feasible in manifold but it cannot bear as high a temperature as 6061-t6 aluminum. Comparatively, the strength of PA66 is lower than that of Aluminum 6061 -t6.

Engineering Plastic vs. Titanium in Car Parts

Titanium is among the best in terms of strength to weight ratio. But, it is very expensive. On the other hand, high performance plastic components in cars can be made at a fraction of the cost. But at the moment no plastic material can match the temperature endurance and yield strength of Ti-6Al-4V (Grade 5) alloy.

Engineering Plastic vs. Steel in Car Parts

Steel is both cost efficient and durable, but it increases the weight of auto part manifolds. As an example, DC04 (CR4 deep-draw) or AISI 1010/1018 steel are deep drawable. Auto parts can be mass produced out of these steel grades with ease. But if the same component are made of plastics the weight can be way less. Hence fuel efficiency can be dramatically increased. Designers keep these factors into consideration during material selection.

How to Choose Matching Plastic to the Part

Plastic materials are made up of different polymers that have a unique set of properties. Each material is suitable for a specific application. As an example. Polycarbonate which is transparent can be used in light covers while PA66 which is heat endurant can be used in car engine parts. Both materials are not interchangeable.

Factors to Consider When Choosing Plastic

Designers consider strength, toughness, surface finish, texture, ease of manufacturing and cost while selecting a plastic material.

Tips for Better Selections

Here are some of the tips for better selection:

- Match performance to function

- Balance cost vs. durability

- Consider manufacturing method

- Use simulation to validate real-world performance before scaling.

A reliable supplier can help in selecting the most suitable materials. TUOFA is a one-stop custom plastic machining solution where we provide solutions right from choosing right plastic to finish machining.

Manufacturing Processes for Plastic Auto Parts

Plastic auto parts manufacturers select the manufacturing process that is cost efficient and scalable. The manufacturing process must suite the geometric features. Precision of the plastic auto parts is another important factor. Let’s discuss these processes one by one.

Injection Molding

Injection molding is the most commonly used manufacturing process for plastic auto parts. It can handle complex geometries and intricate curvatures with ease while maintaining a good throughput.

Blow Molding

Blow molding is commonly used for hollow components like fuel tanks, ducts and bottles. This process gives a good mass production rate.

Thermoforming

Thermoforming is quick manufacturing method for large and thin walled plastic components in cars. Examples include interior panels, liners, and trunk parts.

Extrusion

Extrusion process is used for plastic auto parts that have a constant cross section across the length. Profiles, tubing, seals, and weatherstrips are some of the plastic auto parts that are manufactured by the extrusion process.

CNC Machining of Plastics

CNC machining is generally used for high performance plastic auto parts. As an example, the manifold in car engine must fit precise with other components. CNC machining gives a high precision.

CNC machining is also good for prototyping. Initially there would not be a need to spend money on dies. Rather, CNC machining can carve out the shape out of a blank.

Surface Treatment for Automotive Plastics

At times surface treatment of plastic components in cars become desirable due to cosmetic or functional implications. Some coatings are used to protect the underneath plastic auto parts from weathering. While others are used to enhance the aesthetics.

|

Treatment |

Benefit |

Examples |

|

Pretreatment |

Better adhesive bond |

Bumpers and trims |

|

Coatings |

UV and chemical protection |

Lenses and dashboards |

|

Decorative Finishes |

Premium look and aesthetics |

Grilles, interiors |

Surface Pretreatment Methods

Pretreatment is often needed to modify the surface energy so that the final coating can stick adhesively.

Coatings for Automotive Plastics

Protective coatings are applied to protect the plastic auto parts against UV degradation and chemical attack.

Decorative Finishes

Decorative coatings may add texture or a metallic appearance onto plastic auto parts. It gives them a premium look.

From Prototype to Production: Scaling Plastic Car Parts

CNC machining is an ideal option for manufacturing critical plastic components in cars. It gives a fast turnaround, tight tolerances, and a one stop solution to automotive plastic parts manufacturers. From prototyping to mass production, CNC machining is relevant for any scale.

Rapid CNC Turnaround

CNC machining turns the initial concept into an actual product within a matter of hours. It gives ample time for design validation and alterations.

Tight CNC Tolerances

Plastic auto parts manufactured on a CNC machining can be precise down to a micron. It allows critical underhood components to be manufacturing without any fear.

One-Stop Custom Solutions

Plastic auto parts OEMs usually have a complete one stop solution. They help in design validation, material selection, CNC machining and finishing operations. As an example, TOUFA gives all of these facilities to its clients. Please feel free to share your ideas, we’ll turn it into reality. Just share with us your CAD file and we’ll deliver you he ready components right at your door steps.

Conclusion

The use of plastic in cars is a promising choice to boost up fuel efficiency and mileage. Plastic components in cars are usually very cost efficient. It is easy for plastics to give them complex geometries and intricate curvatures. Plastic auto parts usually have fewer assembling steps than other type of auto parts. At times, the performance criteria like heat endurance and toughness might become a concern. A lot of R&D is being done on this subject to overcome these challenges.

FAQs

Is polycarbonate material used in auto parts?

Yes, polycarbonates are used very extensively in transparent components like light covers and sunroofs.

What thermoplastics are used in cars?

Polypropylene, PMMA, PC, PET, HDPE and LDPE are a few examples of thermoplastics used in cars.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What is Poisson's Ratio? -Definition, Formula, Materials & Design

What is Poisson's Ratio? -Definition, Formula, Materials & Design