Car Chassis Guide: Types, Functions & Custom Solutions

Jun 20,2025

Jun 20,2025

Choosing the right chassis is the first big step in any build, whether you’re restoring a classic or engineering a custom car chassis for an EV swap. This guide breaks down today’s chassis types, shows how tailored frames unlock weight savings and sharper handling, and maps out each design and manufacturing milestone—all in clear, easy language you can use right away.

What Is Car Chassis?

A car chassis is the skeleton of a vehicle. It holds the engine, suspension, and body together while absorbing bumps and crash forces. Without a strong chassis, even the best engine cannot deliver safe, sharp handling.

Frame vs. Unibody: Key Differences

- Frame (Body-on-Frame) – a ladder-shaped steel structure with the body bolted on. Great for trucks and heavy towing.

- Unibody (Monocoque) – floor, roof, and pillars form one welded shell. Lighter, stiffer, and common in passenger cars.

Both layouts influence crash repair cost, weight distribution, and aftermarket upgrade paths, so choose the architecture that best matches your payload, handling, and budget targets.

Core Functions: Strength, Crash Protection, Handling

A good chassis resists bending, shields the cabin in a crash, and keeps wheel alignment stable for predictable steering. It also channels braking loads and road shocks through safe paths, preventing squeaks and preserving panel gaps over years of use.

How Chassis Geometry Affects Ride Quality

Wheelbase, track width, and suspension pick-up points govern response and comfort. A longer wheelbase glides over bumps, while wider tracks curb roll. Minor tweaks to camber gain or anti-dive can sharpen feedback without ruining daily drivability.

Common Car Chassis Types Explained

The auto industry uses four main architectures. Each solves a different design problem.

| Chassis Type | First Use | Best For | Typical Materials | Weight Trend |

|---|---|---|---|---|

| Ladder Frame | 1900s | Heavy trucks, 4×4 | Mild steel | Heavy |

| Backbone Frame | 1960s | Sports cars | Box-steel spine | Medium |

| Monocoque/Unibody | 1940s | Most passenger cars | Pressed steel, aluminum | Light |

| Space/Tubular Frame | 1930s | Race & kit cars | Round steel/aluminum tubes | Very Light |

Ladder Frame

The dual-rail design is simple and strong but heavy. Cross-members can be welded in anywhere for custom mounts, yet the high center of gravity can hurt cornering, so builders often add roll cages or gussets for extra rigidity.

Backbone Frame

A center spine carries drivetrain loads, trimming weight in low-volume sports cars. Side-impact strength needs extra box sections, but the layout frees door sills for sleek styling and easy exhaust routing down each flank.

Monocoque / Unibody

Stamped panels spot-weld into a stiff shell that integrates modern crash zones. The method cuts mass and cost, but repairs demand factory fixtures and careful corrosion protection to keep long-term strength intact.

Space Frame & Tubular Designs

Triangulated tubes deliver extreme stiffness per kilogram. Engineers can mix steel and aluminum members to tune crush behavior, but the many welds require tight jigs and skilled labor, adding fabrication hours.

Why Choose a Custom Car Chassis?

Mass-production frames suit the average driver. Enthusiasts and niche OEMs want more.

Lighter & Stronger

Trimming 15–25 % mass while raising torsional stiffness by 30 % slashes lap times and fuel use. Less weight means quicker acceleration and shorter stopping distances, while stiffer structures keep windows sealed and dashboards rattle-free.

Powertrain Freedom

Bespoke rails and mounts swallow batteries, mid-engines, or hybrid gearboxes. Designers can slide firewalls, drop floors, or invert differentials, unlocking layouts impossible with stamped factory rails.

Sharper Handling

Custom pick-up points set roll centers, anti-squat, and caster exactly to the model. Drivers feel faster response, balanced cornering, and even tire wear on long highway runs.

How to Design for Custom Chassis Projects?

A safe, road-ready structure starts on a screen long before tubes meet a welder.

What Are the Best Material Choices for Custom Chassis?

Selecting the right metal—or composite—sets the ceiling for chassis stiffness, crash energy absorption, and long-term fatigue life. Below is a side-by-side look at the three families engineers reach for most often.

| Material Family | Typical Grades & Condition | Tensile Strength (MPa) | Density (g/cm³) | Practical Pros | Practical Cons |

|---|---|---|---|---|---|

| High-Strength Steel | DP800, 4130 (normalized), 22MnB5 (press-hardened) | 800 – 1,500 | 7.8 | Cheapest $/kN, easy welding & forming | Adds weight; galvanic corrosion if bolted to aluminum |

| Aluminum Alloys | 6061-T6, 6082-T6, 7075-T6 | 310 – 570 | 2.7 | 35–50 % lighter than steel, CNC-friendly | Needs thicker sections; 7075 cracks when welded |

| Composites | Carbon T700/T800, S-Glass/epoxy | 600 – 4,000 (fiber) | 1.6 – 2.0 | Best stiffness-to-weight, resists corrosion | High cost, labor-intensive lay-up, repair difficulty |

1.High-Strength Steel

Modern dual-phase and martensitic steels rival chromoly tube strength without exotic gas. Press-hardened 22MnB5 rails achieve ≥1,500 MPa after hot stamping, making them perfect for crumple zones and rollover hoops.

2.Aluminum

- 6061-T6 offers 310 MPa tensile strength at half the mass of steel.

- 6082-T6 adds about 10 % strength and better fatigue life, ideal for EV floor pans.

- 7075-T6 jumps to 570 MPa but dislikes welding, so builders bolt or rivet these members after forming in a softer O-temper and post-aging to T6.

3.Composites

T700 carbon pre-preg tubs reach 4,000 Nm/deg torsional stiffness at ultralight weight. Aluminum crush cones bonded into the laminate spread bolt loads without hefty steel inserts.

Rule of Thumb: Match material to budget and joining method first; chase ultimate strength only after weld, bond, or rivet constraints are solved.

How to Predict Loads & Tune Stiffness?

Engineers map tire forces, then iterate FEA until torsional rigidity meets target values. Simulations expose stress hot-spots early, letting teams trim idle metal and reinforce weak joints before cutting actual tube.

How to Build-In Safety & Crashworthiness?

Identify Applicable Test Standards (FMVSS, ECE, JNCAP)

Rails and joints must fold in controlled stages during impact, soaking energy before it reaches the cabin. Virtual sled tests guide gusset sizing and trigger beads so prototypes pass physical crash labs on the first try.

How to Cut Cost of Your Custom Chassis Project?

Modular jigs and one-stop CNC partnerships trim labor, freight, and tolerance drift. Shared fixtures cover multiple wheelbases, and single-plant logistics prevent damage or misalignment between outsourced steps.

Manufacturing Methods for Custom Chassis Components

From raw tube to painted frame, precision matters.

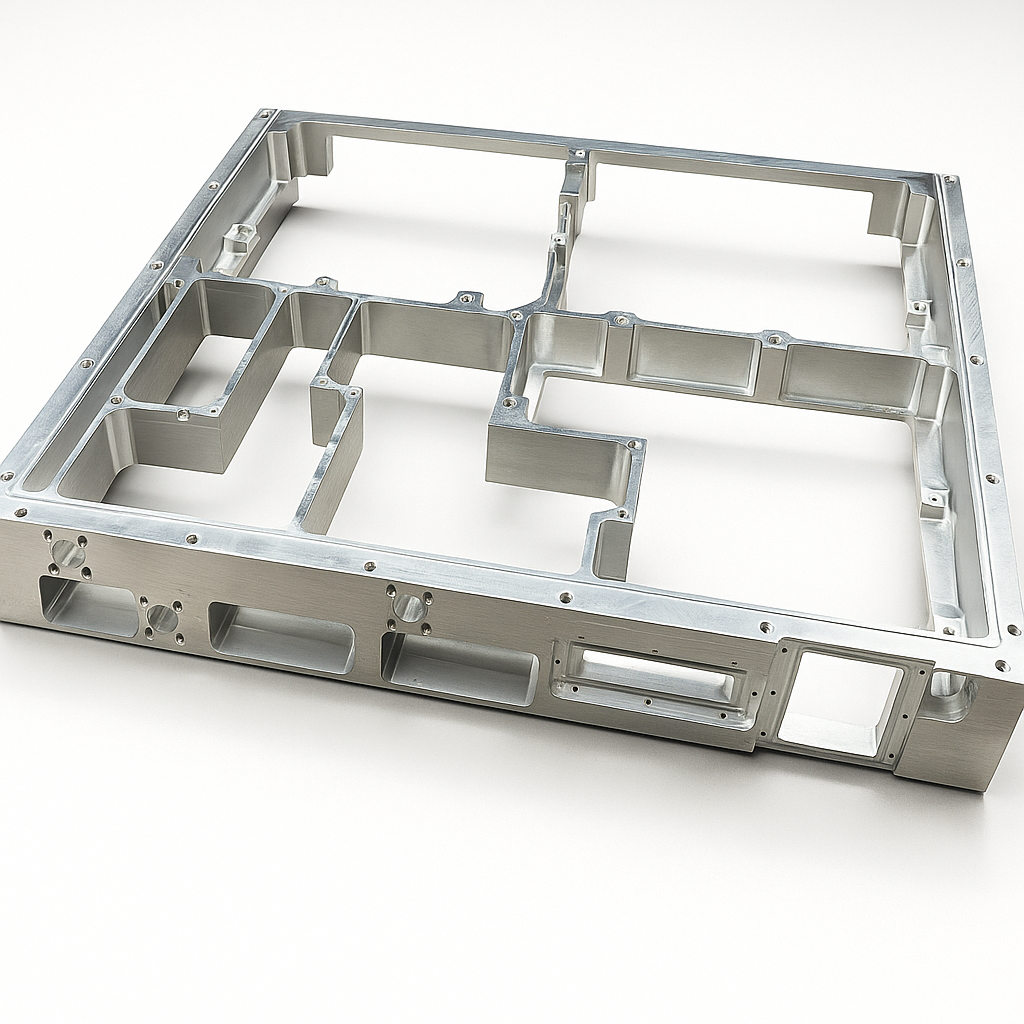

CNC Precision Machining

Five-axis mills hold ±0.02 mm, critical for suspension knuckles and steering bosses. In-cycle probing checks every pocket, sparing builders from hand reaming and guaranteeing bolt holes line up first time.

Sheet Metal Fabrication

Water-jet and press-brake lines fold 2–3 mm aluminum tubs with tight radii and minimal heat. Integrated flanges speed welding or riveting, boosting strength while controlling cost.

Surface Treatments for Corrosion Resistance

Zinc spray, e-coat, or clear anodizing shrug off 1,000-hour salt-spray cycles. Matched primer systems let paint bond tightly, giving showroom gloss that survives harsh winter roads.

Integrating Suspension & Drivetrain into a Custom Frame

Geometry and service access define long-term satisfaction.

Determining Suspension Pickup Points

Laser-cut tabs anchor arms within ±0.1 mm, locking camber gain, scrub radius, and bump steer. Subsequent adjustments need only shims, saving track-side setup time.

Modular Subframes for Serviceability

Drop-out cradles carry engines and gearboxes on isolated bushings. Clear bolt access halves service hours, lowering fleet costs and making weekend power upgrades painless.

Managing Noise, Vibration & Harshness (NVH)

Hydro-formed rails and rubber mounts cut boom above 200 Hz. Strategic foam fills and composite panels damp mid-range resonance, keeping cabins quiet even with stiff springs and low-profile tires.

Choosing the Right Custom Chassis Partner

Execution quality determines program success.

Essential Engineering & CAD Capabilities

Seek suppliers with CATIA, SolidWorks, and validated crash models. Proven simulation chops show they can predict performance before metal is cut, slashing prototype cycles.

Quality Certifications & Testing Facilities

ISO 9001, PPAP packs, metallographic micrographs, and weld-pull tests confirm robust process control. Reliable paperwork equals consistent frames arriving on spec.

From Prototype to Large-Volume Production

How to make your custom car chassis project for large volume production? Looking for a professional CNC machining parts factory would help a lot. TUOFA CNC Machining, a precision CNC machining parts factory, has been working in custom machining for nearly 20+ years. Shared fixtures mean prototypes and production frames pass through identical quality gates, compressing lead-times dramatically.

Conclusion

A custom chassis cuts weight, frees packaging, and sharpens handling. Partner early with experts who integrate design, FEA, and machining under one roof to turn sketches into road-ready metal without costly detours.

Custom Car Chassis FAQs

How much does a custom chassis cost?

Basic tubular frames start near $8,000, while carbon tubs exceed $80,000. Complexity, material, and order size shape the final quote.

Is aluminum strong enough for off-road chassis?

Properly gusseted 6061-T6 can match steel strength at half the weight but needs regular crack inspection, especially around welded joints.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Precision Gearing 101: From Parameters to Machining

Precision Gearing 101: From Parameters to Machining