What Is Progress Stamping? How It Work?

Aug 18,2025

Aug 18,2025

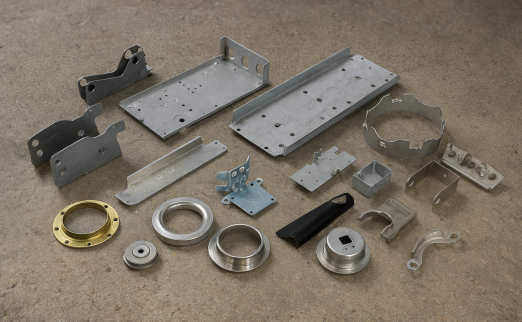

Progressive stamping is a versatile process that helps in increasing efficiency and cost-effectiveness of parts during manufacturing. It can create metal parts with different shapes and sizes which decrease the production cost and lead time. But questions arise here, how and where we can use this accurately in our manufacturing process or what type of equipment is used in this process. This article will give you deep insight into the topic and all the essential details.

What Is Progressive Stamping

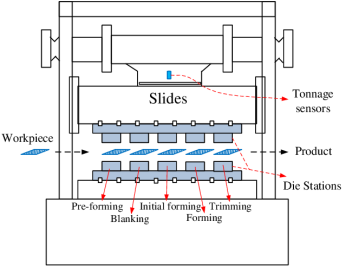

It is a metal forming process in which a series of specialized dies is used to make a finished from a continuous metal strip in a single machine stroke. It has multiple stations which perform specific operations such as piercing, blanking, forming, coining, or cutting off. This is all done in a sequence because the material advances through the stamping die.

What is Precision Stamping?

It is a subclass of metal stamping which is used to achieve very tight tolerances and high accuracy in the final product.

How Does Progressive Die Stamping Work?

The progressive die stamping works in a continuous process. Meta strip is introduced through the die, and each stroke of the press completes full cycle. This can produce one or more finished products.

Progressive Stamping Process Flow

The process flow normally has various steps. The detail of each step is given below:

Step 1: Coil Prep & Straightening

Process starts with uncoiling of metal coil. It then passed through a straightener and curvature is removed to have a flat surface and consistent feed.

Step 2: Layout & Pilots

In this stage, pilot holes are created to accurately locate the strip at each station. This must have proper alignment for following operations.

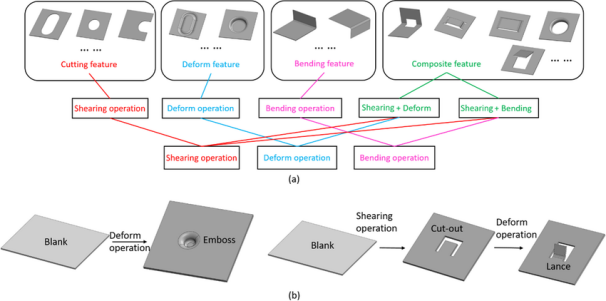

Step 3: Pierce & Blank

In this stage, cutting the basic shape of the part is done and also creates any necessary holes or openings, if needed.

Step 4: Form & Bend

Metal part is bent or shaped into required form in 3-dimesional format by using a series of punches and stamping dies.

Step 5: Coin & Emboss

Finer details of the part such as raised or recessed or embossed features are done by using pressure onto the metal in this stage.

Step 6: Cutoff & Scrap

At this stage, finished part is separated from the carrier strip. The remaining skeleton is cut into scraps for recycling.

Progressive Die vs Single-Stage or Transfer Stamping

Progressive die and transfer die stamping both are multi-station metal stamping processes. However, they have different ways of handling workpieces and have different suitability for complexity or production volume.

Part Complexity

Progressive die is good for moderate to high complexity parts and for smaller parts. While transfer die is versatile for large and complex parts with deep draws or intricate geometries.

Applicable Scenarios

Progressive is good for high production volume of small to medium-sized parts. Transfer die is best for large and complex parts for aerospace and automotive parts.

Workflow Differences

Progressive die has a metal strip move continuously through a series of stations in a single die. They all perform different operations performed simultaneously on multiple parts. Transfer die has separated workpiece from strip and then transferred between individual dies at different stations.

Cost Comparing

Progressive die has lower cost per part for very high volumes. Transfer die can be more cost-effective for lower production volumes or for complex geometries parts.

How Accurate Is Progressive Stamping

This technique has high precision with the tolerance ranges between ±0.01mm to ±0.1mm. However, multiple factors like material and stamping die design affect the final tolerance. High-volume production with design consistency and accuracy can be achieved. But is has a few drawbacks like higher initial tooling costs and chance of tool wear with abrasive materials.

Accuracy and Tolerances

It is known for its tight tolerances and is suitable for stamping parts requiring high precision. The normal tolerance ranges are ±0.01mm for hole diameters and dimensions in <1mm thickness, and ±0.1mm for larger features.

Benefits in Precision Progressive Stamping

There are many advantages associated with precision stamping:

- It can achieve high precision and tight tolerance with automated material feeding and die design.

- High volume production with consistent quality.

- Low labor cost, less material wastage and overall cost-effective for large production.

- Versatile process and make stamping parts with different geometries and complexities.

- Optimized process with low scrap and environmental friendliness.

Drawbacks and Limits

Precision stamping also has some drawbacks and these are:

- High initial investment due to complex multi-station die design.

- Hard material may cause tool wear.

- Extreme draw and sharp angles can be difficult sometime but possible with transfer die stamping.

- punch can break edge during manufacturing.

What Equipment Are Used in Progressive Stamping

The key equipment used in progressive stamping and machining are discussed below:

1.Feeder

This part is used to feed the metal strip into the press. It allows a continuous and controlled flow of material.

2.Die Set

The die set has all the essential dies to perform different operations. For example, cutting, bending, forming, etc. to do on the metal strip as it passes through the press.

3.Stripper

These stripper plates remove the finished stamping part from the punches after each stroke of the press. This prevents part from sticking.

4.Press

It provides force and motion needed for the stamping process. It drives the die set and performs different operations.

When to Use Custom Tooling?

There are certain scenarios when to use custom tooling. These are for high-volume production, which is efficient for large quantities, complex geometries that require multiple operation of bending, piercing or forming and for tight tolerance and high precision parts.

Custom tooling is not recommended for low production volume, simple part designs and for quick turnaround.

Design for Manufacturability in Progressive Dies

Progressive die design require careful consideration of design for manufacturability DFM. The key factors are discussed below:

Tolerances and Datum Strategy

Right selection of tolerance for different materials like steel or aluminum alloys helps the part to meet specifications. Datum strategy is the reference point for manufacturing and is essential for consistent part production.

Features and Forming Rules

Bend, draw or hole making feature affect the die complexity. Forming rules define the material behavior during these operations to have a flawless part formation.

Material Selection Tips

Right material selection is essential for higher strength, formability, and cost-effectiveness.

Carbon and Stainless Steels

They are versatile and have many applications like 1008/1010 low-carbon steel is good for simpler parts and stainless steels have high corrosion resistance and strength.

Aluminum and Copper Alloys

Aluminum stamping parts like 5052-H32 and 6061-T6 are lightweight and have good formability. Cu alloys like C260 are also used for electrical or thermal conductivity applications.

Tool Materials Selection

Right tool material selection is important for high wear resistance and durability for high-volume production.

Quality Control

Using robust quality control procedures during the manufacturing process creates final parts that meet the required standards.

Progressive Stamping and CNC Machining

There are several scenarios that help to select the right process. Stamping is preferred for high-volume production of parts with repeated features like holes. CNC machining is better for low and large volume, high-precision parts with tight tolerances. Sometimes, you can get a reasonable price if you choose the right supplier.

Where Choose Stamping over CNC Machining

Stamping is best for large quantities of simple parts. It is used when speed and cost-effectiveness are important. Dies are formed for specific shapes, and the process is very effective for high volumes.

Where Choose CNC Machining over Stamping

CNC machining is good for high-precision parts, volume from low to large. It is used for specific features like tight position tolerance, countersinks, and complex geometries. It also has high flexibility and precision, but it is slower and more expensive for large quantities.

Need help to decide the right manufacturing process for your project? Contact TUOFA today for a free consultation! We will provide an accurate quotation shortly once we get the technical drawings and we offer instant quote service online!

When to Use Stamping and CNC Machining

It is a good strategy to combine both techniques for complex parts. Stamping is used for the initial forming and shaping and CNC machining is used for fine details and critical tolerances.

Conclusion

Progressive stamping or progressive die stamping is a metal forming process. It has a series of workstations within a single die to convert a metal strip into a finished part progressively transform. It is done by feeding metal coil into machines and advances through the die. Die has multiple stations which perform different functions like cutting or bending and then metal is gradually shaped to final product. It is best for high-volume production of complex parts with tight tolerances.

FAQs on Progressive Stamping

What is the difference between a stamping die and a progressive die?

Progressive die is a type of stamping die. It performs multiple operations in a single press stroke and standard stamping die does a single operation per stroke.

Which metals are best for progressive stamping?

Metals like aluminum, copper, brass, steel and stainless steel can be selected for progressive stamping based on strength, ductility, and cost-effectiveness.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What is Cellular Manufacturing? -A Lean Manufacturing Method

What is Cellular Manufacturing? -A Lean Manufacturing Method