Nylon vs. Polyester: A Complete Engineering Plastics Guide

Sep 11,2025

Sep 11,2025

Nylon and Polyester come from a broad category of polymers. Nylons belong to polyamide and polyester are mostly related to polyethylene terephthalate (PET) polymers. Bothe are engineered materials and are used in different engineering applications for their high heat, chemical and wear resistances. An in-depth analysis of the compositions, properties, applications and pros and cons of Nylon and polyester are discussed in this article.

What Is Nylon?

Nylon is a commercial name for synthetic polyamide polymers. These are high strengthened and durable engineering plastics which also have high elasticity, toughness, and wear and chemical resistances.

These are different from polyester because of having amide bonds in its molecular structure.

Composition of Nylon

Nylon is thermoplastic polymer and formed by reaction between diamines and dicarboxylic acids. It forms a repeating amide linkage that gives it its characteristic properties.

Relationship of Nylon and Polyamide

Nylon is a specific type of polyamide. Polyamide has amide linkages in repeating unit and nylon is the commercial name of these synthetic aliphatic polyamides.

Grades of Engineering Nylon Materials

Nylon has different grades with varying properties.

1.Nylon 6 and Nylon 6/6: 80% Chosen

Nylon6 or polyamide 6(PA6) has single 6-carbon monomers with ring-opening polymerization. It is used in 80% of the applications because it has lower processing time, less mold shrinkage and high impact and fatigue strength. Nylon6/6 (PA66) is made of two monomers which are hexamethylenediamine and adipic acid by polycondensation. It is another grade with high tensile strength, wear resistance and toughness used frequently.

2.Nylon 12 (PA 12): 10% Chosen

Nylon 12 has 12-carbon monomers like laurolactam. It is used in 10% of the applications because of its higher chemical resistance, to oils, fuels, and hydraulic fluids. It also has high strength, stiffness, and resistance to cracking under stress.

3.Nylon 11 (PA 11): 5% Chosen

Nylon 11 is polyamide, bioplastic and has 11 carbon monomers. It is used 5% because it has high elasticity, high elongation, impact resistance and thermal stability.

4.Nylon 6/12 (PA 6/12): 5% Chosen

Nylon 6/12 has 6 carbon monomers like lactam or amino acid and 12 carbon monomers of dodecamethylenediamine. It is a copolymer derived from Nylon 6 and Nylon 12. It is used in 5% of the applications and has higher flexibility and impact resistance than PA 6 or PA 6/6.

Engineering Nylon Plastic Applications

Nylon has many engineering applications like for industrial components (gears, bearings, rollers), automotive parts (engine covers, fuel tanks) and for electrical insulation (connectors, switches).

What Is Polyester?

Polyester is linked by ester groups with Polyethylene Terephthalate (PET) and Polybutylene Terephthalate (PBT). They have high strength, chemical resistance, dimensional stability, and thermal properties.

Composition of Polyester

Polyester has long-chain synthetic polymer molecules of PET and dicarboxylic acid and diol. The polyester density is range from1.23-1.38 g/ml, but specific values change, depending on the type of polyester and its manufacturing process.

Grades of Engineering Polyester Materials

There are few common grades of polyester materials that are used in many engineering applications.

1.PBT: 60% Chosen

Polybutylene Terephthalate (PBT) is a thermoplastic polyester which is used 60% due to its high chemical resistance, electrical properties, and molding suitability.

2.PET: 25% Chosen

PET is polyethylene terephthalate and is one of the hardest plastics and is used 25% in applications. It is easy to reshape and mostly used in packaging material.

3.LCP: 10% Chosen

Liquid Crystal Polymer (LCP) is used in 10% due to its high tensile strength and tensile modulus in the direction of flow. It also has very low melt viscosity.

4.PCT-G: 5% Chosen

PCT stands for Polycyclohexylenedimethylene Terephthalate and is used in 5% because of high clarity, high gamma stability, and very high impact strength.

Engineering Polyester Plastic Applications

Engineering polyester like PET or PBT is used in many applications like food and beverage packaging (bottles, trays), automotive components (bumpers, fuel tanks), and electrical and electronic parts (insulation, circuit boards, connectors).

Nylon vs. Polyester: Mechanical Properties

Engineering Nylon has high strength, elasticity and wear resistance in general while engineering polyester has high stiffness, dimensional stability and chemical resistance. Mechanical properties are important for performance, durability and safety of the product.

Tensile and Stiffness

Nylon tensile strength is higher than polyester. Nylon also has better abrasion resistance and elongation. Polyester is also strong, but it is stiffer and has less elongation.

Impact and Fatigue

Nylon has higher impact resistance and fatigue resistance. Polyester has good surface hardness but less impact and fatigue resistance.

Creep and Wear

Nylons have higher wear resistance and ductility and are good for gears and moving parts. Polyester has less inherent wear resistance

polyamide vs polyester Mechanical Properties

|

Property |

Nylon |

Polyester |

|

Tensile Strength & Stiffness |

Higher |

Good strength |

|

Impact resistance |

Better impact resistance, |

Stiffer and more brittle |

|

Creep & Wear |

Higher wear resistance |

Less inherent wear resistance |

|

Fatigue Resistance |

Good fatigue resistance |

Less |

Nylon vs. Polyester: Moisture and Dimensional Stability

Moisture and water absorption can affect size and fitting of Nylon and polyester. polyamide vs polyester has different rates of absorption which further influence their dimensional stability.

Water Absorption

Nylon can absorb 3-5% moisture which causes swelling and reduces its strength up to 15%. It is not very reliable in wet conditions and can weaken its dimensions.

Polyester absorbs 0.4% moisture due to its hydrophobic nature. It can maintain its strength and dimensions in wet conditions.

Size Change and Tolerance Control

Nylon has less dimensional stability due to high moisture absorption. It is not suitable for the application of tight tolerances or precise dimensions.

Polyesters can maintain their dimensional stability and can retain their shape and size under various stresses and environmental conditions.

Assembly Fit and Sealing Stability

Nylon fitting may get loose, or part can expand due to moisture absorption. Nylon sealing may lose its integrity with the swelling.

Polyester has consistent dimensional stability, and its seals are stable and reliable in humid or wet environments.

Nylon vs. Polyester: Thermal and UV Performance

Thermal and UV performance are essential in outdoor applications of engineering plastics. Nylon vs. polyester thermal performance is discussed below:

Continuous Use Temperature

Nylon is suitable for operating temperatures up to 200-210°C. Higer temperature tolerance and melt points are possible with Nylon.

Polyester has lower heat stability and is prone to melting at high temperatures.

Heat Aging and Hydrolysis

Nylon is prone to hydrolysis. It can lose its strength in hot and humid environments unless stabilized.

Polyester has better resistance to hydrolysis and performs well in heated and damp conditions.

UV Resistance and Color Hold

Nylon degrades when exposed to ultraviolet light. It is susceptible to damage from UV radiation.

Polyester naturally resists UV degradation and holds its color over time.

Nylon vs. Polyester in Automotive Components

Nylon has better mechanical strength, elasticity, and low friction properties. while polyester has better UV resistance and chemical stability. There are many suitable applications for their respective features.

Connectors and Sensor Housings

Polyester and Nylon can both be used in connectors and sensor housing but have some limitations too. These are discussed below

Advantages:

Nylon has:

- High mechanical strength and resilience and can survive vibrations and temperature fluctuations

- Chemical resistance for automotive applications

- Better insulation properties

Polyester has

- Better UV resistance

- Low moisture absorption and work better in damp condition

- High temperature resistance

Disadvantages:

Nylon has limitations due to:

- High moisture absorption can lose strength

- High temperature limitations

Polyester has limitations for connector and housing applications due to:

- Its less elasticity or resiliency as nylon

Gears, Bushings, and Bearing Cages

Nylon and polyester have pros and cons for the applications of gears, bushings, and bearing cages.

Advantages:

Nylon has

- Low friction & self-lubrication

- High strength and wear resistance

- Noise damping and helps in reducing noise and vibration

Polyester has

- High rigidity and strength

- Excellent sliding properties for smooth, consistent movement.

Disadvantages:

Nylon has

- Temperature limitations and cannot be used in very hot engine parts.

- Moisture sensitivity

Polyester has

- Less flexibility and not suitable for high impact or flex.

Under-hood Brackets and Ducts

Polyester and Nylon are both used in under-hood brackets and duct. Their pros and cons are:

Advantages:

Nylon has

- Exceptional Strength and Resilience and suitable for brackets and supports

- Durable against Chemicals and Oil common under the hood.

Polyester has:

- High-temperature resistance to engine heat

- higher UV resistance

Disadvantages:

Nylon has limitations of

- Temperature sensitivity for extreme heat of the engine bay.

- Potential moisture issues can affect its dimensional stability over time.

Polyester has

- Less flexibility for ducts or brackets

Nylon vs. Polyester: Chemical Resistance

Polyester is normally preferred for oils, fuels, and coolants. It has better chemical properties but there are few more things to understand these features.

Compatibility with Fluid Family

Polyester has better resistance for a huge variety of chemicals and acids. It is less affected by water and other fluids but susceptible to strong alkalis.

Nylon is resistant to oil but can be degraded by strong acids or bases. It can break its amide bonds and will cause degradation.

Friction and Noise

Nylon has high abrasion resistance, durability and strength. It can create a smoother and lower-friction surface in wear pairs.

Polyester also has durability and abrasion resistance but less than nylon. Polyester has more friction in wear applications and is prone to static electricity.

Wear Pairs and Coatings

Nylon is preferred to wear pairs due to its inherent abrasion resistance and smoother surface.

Polyester is not that ideal for high-wear applications and may require specialized coatings to improve performance.

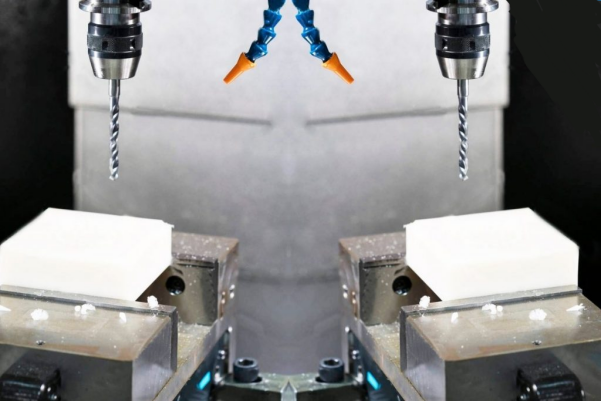

Nylon vs. Polyester: Processing and Molding

Nylon and polyester can be processed and molded by CNC machining.

Machining Nylon CNC

Some key properties of Nylon that to be kept in mind while machining are its high abrasion and wear resistance, low friction, high impact strength, and mechanical properties.

Coolants are highly recommended to maintain the dimensional stability of Nylon. The cutting parameters for nylon (PA66) are 200-300 ft/min speeds, feed rates 0.002-0.008 in/tooth, and depth of cut 0.020-0.050 in. polished and bead-blasted finished can get a uniform, matte, or glossy finish. normally machined parts made are brackets, small gears, bushings, and bearings.

Machining Polyester CNC

Polyester has high strength, stiffness, impact, and wear resistance.

It can be easily machined to very tight tolerances for high-precision applications. Commonly machined parts are precision frames and components.

How to Mold Nylon and Polyester?

To mold Nylon and Polyester, these steps are followed:

- Dryingof nylon or polyester to remove moisture content.

- Meltingof dried material (chips or pellets) in the injection molding machine.

- Injectionof molten plastic under high pressure into a mold cavity.

- Coolingand solidification of material to its final shape.

- Ejectionof molded part from the mold.

Nylon vs. Polyester: Who is Cheaper in Machining?

Overall, the cost of material depends on its type and grade, the machining cycle time, and the surface finishing of the engineering plastics.

1.Material Price

Polyester is more cost-effective but has a complex production process. Nylon is expensive in terms of material stock.

2.Machining Cycle Time

Polyester has higher machining expenses, but with less tool wear. Nylon machined at higher speeds, with less cycle time.

3.Surface Finishing Labor

Polyester has lower-cost finish and can save on labor for certain products. Nylon requires more specialized finishing processes.

Other Factors

There are other factors like recyclability, cost vs durability for Nylon and polyester. Interested in getting in-depth information about other cost factors? Contact TUOFA engineering plastic machining shop!

Conclusion

Engineering nylons have high strength, impact resistance, and abrasion resistance. It is best for structural and high-wear applications such as automotive parts. Whereas polyester has better moisture resistance, dimensional stability, and UV resistance. It is mostly used in precision components and outdoor applications. The selection of these two engineering plastics depends on the different factors like strength, flexibility, moisture, and environmental resistance.

FAQs

Which is stronger, nylon or polyester?

Nylons are stronger than polyester because it has higher tensile strength and elasticity.

Does nylon absorb more water than polyester?

Yes, nylon absorbs more water than polyester. Because it is hydrophilic and absorbs water while polyester is hydrophobic or a water repellant plastic.

Which is better for under-hood automotive parts?

There is not any best material for under-hood automotive parts. The selection is based on properties requirements like heat resistance, durability, and chemical resistance.

Can recycled PET replace nylon in my application?

It depends on the property’s requirements. For example, nylon has high strength, elasticity, and water resistance but recycled PET is used for bulk, softness, and lower breathability applications.

Is nylon durable?

Yes, nylon is highly durable. It has high strength, abrasion resistance, and wear and tear resistances.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

All You Need to Know About UHMW: Machining Material Guide

All You Need to Know About UHMW: Machining Material Guide