Torsional Rigidity in CNC Machined Parts: Design Methods

Jan 06,2026

Jan 06,2026

Torsional rigidity is an important engineering factor in CNC machined parts. In simple words, it is twisting rigidity and correct amount of rotational stiffness is crucial in engineering designs. For example, if rigidity is high, it makes part heavy and brittle, and much lower makes part broken or flop around and break. Understanding torsional rigidity is essential to determine the stability of parts. This article will give you deep insight into the torsional rigidity and its important aspects.

What Is Torsional Rigidity

It indicates the level of twisting to a part without damage. Torsional rigidity helps in development of structures of CNC machined parts that need to retain their working and geometry under twisting loading conditions.

Definition and Physical Meaning

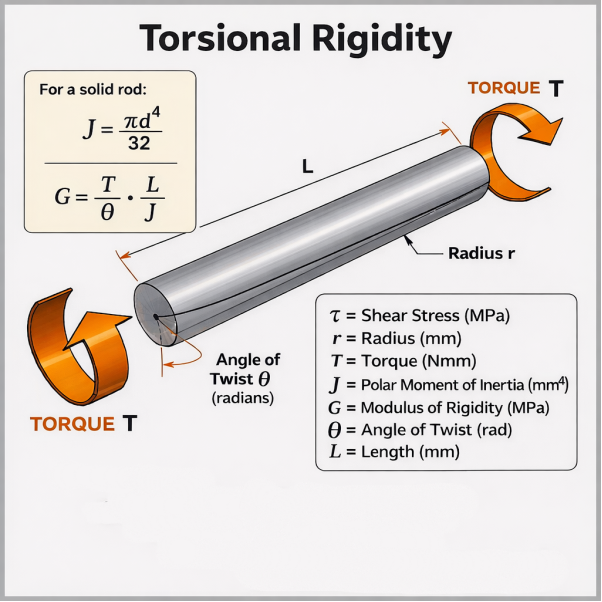

Torsional rigidity is the product of shear modulus (G) and the polar moment of inertia (J) of a cross-section. It is the torque that is required to create a twits of one radian per unit length. The torsional rigidity formula is GJ, and its unit is Nm(Newton-meters)

Torsional Rigidity vs Torsional Stiffness

Torsional stiffness(k) is the torque to produce a specific unit of angular twist like one degree. Rigidity is an inherent property of any material and cross-section while stiffness is a property of entire components like: material + shape + length

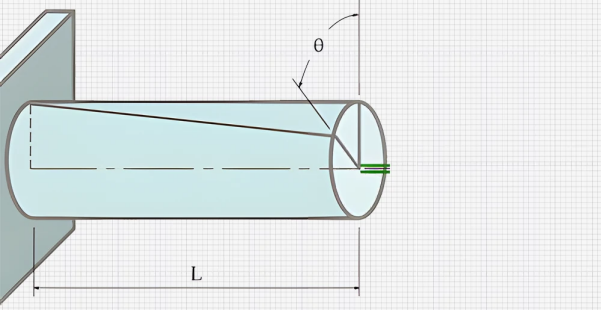

Torque, Angle of Twist, and GJ

Torque (T) is the twisting moment applied to a long shaft. While the angle of twist(θ) is the resulting angular displacement of the shaft, measured in degree or radian.

The fundamental torsion equation relates this relationship: T/θ=GJ/L=k

This means for a given torque (T), a higher GJ (rigidity) shows smaller twist (θ), and higher GJ needs more torque stiffness.

Key Parameters and Formula for GJ

The formula GJ is the measure of a resistance to angular deformation in a material when torque applied to CNC Machined parts. The two key parameters of this measurement are the material shear modulus (G) and the polar moment of inertia (J).

Shear Modulus G

Shear modulus (G) is also known as the modulus of rigidity. It is an inherent material property that describes a material's resistance to shear deformation, and its SI unit is Pascal (Pa) or Gigapascals (GPa). This value is unique for each material. For example, the G values for steel are significantly higher than those for aluminum. This means a steel shaft is much stiffer than an aluminum shaft of the same dimensions.

Polar Moment of Inertia J

The polar moment of inertia (J) is a geometrical feature property of a shaft's cross-section. It determines the twisting or bending rigidity of shafts, and its SI unit is m4. The formula for the polar moment of inertia for solid circular shaft of radius is

J=πR4/2,

while for a hollow circular shaft with outer radius Ro and inner radius Ri, it is:

J = π(Ro4 - Ri4) / 2

Torsional Rigidity Formula and Units

Torsional rigidity shows the combined material and geometric resistance to twisting. The unit for torsional rigidity (GJ) is N⋅m2. The primary formula relating torque (T), angle of twist (θ), and length (L) to torsional rigidity is:

GJ=TL/θ

Typical Shear Modulus Values Table

G values are different for each material. A higher G value means material is stiff. Some examples of common engineered materials are:

|

Materials |

G values (GPa) |

|

Carbon Steel |

77 - 80 |

|

Stainless Steel |

77 - 86 |

|

Aluminum Alloys |

24 - 28 |

|

Magnesium |

16.5 - 17 |

|

Nylon (Polymer) |

3.9 - 4.1 |

|

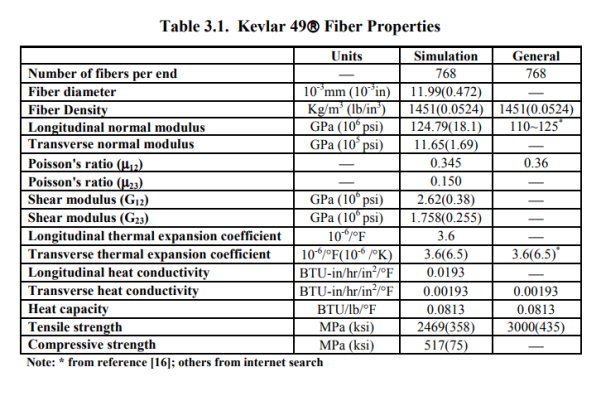

Composite (Kevlar) |

(≈G12) = 2.1–2.14 GPa |

*Kevlar’s G values are cited from NASA Technical Reports.

Material Effects on Torsional Rigidity

Material selection for CNC machining can significantly alter the torsional rigidity. Metals have high rotational stiffness in high-torque parts, while polymers are lighter and not preferred for demanding roles.

Metals in Torsion Loaded Parts

Typical metallic materials like 4140 steel or 6061-T6 aluminum alloys offer high torsional stiffness with G ~80 GPa and G ~26 GPa, respectively. These alloys are best for shafts, gears and other structural parts like lightweight drone arms or bicycle frames. Another one of the common metals, 17-4PH stainless steel, is known for its strength and highly used in torque stiffness applications.

Polymers and Composites in Torsion

Polymers like polyethylene, polycarbonate normally have lower shear modulus of G ~0.2-1.0 GPa. These are used for lighter parts like pipes, casings, and some drone parts. while composites have high strength-to-weight and excellent torsional stiffness with G ~5-20 GPa (depending on fiber orientation and layup). These are used in high-performance sports equipment, drone frames and bicycle frames.

Comparing Shear Modulus across Materials

As mentioned above, metals have superior shear modulus. High modulus means high torque needed for the same twist or higher torsional rigidity. A general trend of shear modulus for different CNC materials is like Steel > Aluminum > Composites > Polymers.

Torsional Rigidity Comparison Table

Torsional rigidity is the product of shear modulus (G) and polar moment of inertia (J). a comparison of the torsional rigidity for common materials is:

|

Materials |

Shear modulus |

Polar moment of inertia |

|

steel |

High |

High |

|

Aluminum |

Medium |

Medium |

|

Composite (CFRP) |

High |

High |

|

Polymer |

Low |

low |

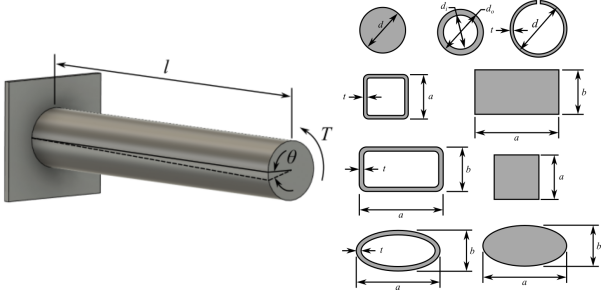

Geometric Effects on Torsional Rigidity

Polar moment of inertia is a geometric property and are crucial. High inertia results in higher torsional rigidity. A circular (solid) shaft is efficient for uniform stress distribution while a hollow or shaft has higher inertia for the same amount of solid material. A thin-walled or a rectangle section has more complex stress distribution but has unique stiffness-to-weight benefits.

Torsional Rigidity in Shafts and Drive Components

Torsional rigidity in shafts and drive parts is important for their efficient torque transmission, dynamic behavior, and long service life. And for precision machined shafts, torsional rigidity, allows minimal deformation for accuracy. High rigidity minimizes twisting under load and poor rigidity can cause premature failure.

Power Transmission Shafts

Parts like gearboxes and industrial drives transmit power between motors and machinery like turbines and need high torsional rigidity for accuracy and stability. Pump shafts need torsional vibration and bending resistance to perform properly and must be corrosion resistant as well.

Drive Shafts and Propeller Shafts

Marine parts like propeller shafts transmit engine power to propellers ++ and accommodate suspension movement. They need torsion, bending, vibration, and corrosion resistances and therefore made from stainless or high alloys.

Couplings and Joints

Coupling and joints connect shafts, transmit torque, and absorb shock or vibrations. Rigid couplings have simple sleeves (muff couplings) for low torque to have perfect alignment. And flexible couplings like U-joints, CV joints allow for misalignment like angular or parallel. They can absorb torsional shock and are crucial for vehicle drive trains.

Torsional Rigidity in Vehicle Chassis Design

Torsional rigidity is the chassis’ ability to resist twisting forces from cornering or uneven terrain. A stiffer chassis in machined vehicle parts is crucial for overall vehicle control and durability.

Chassis Twist Deign

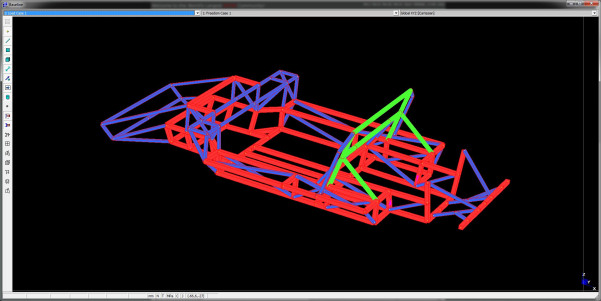

Triangle bracing with cross tubes or struts is a lightweight way to add rigidity in chassis design. Adding reinforced cross members can significantly boost stiffness. Furthermore.

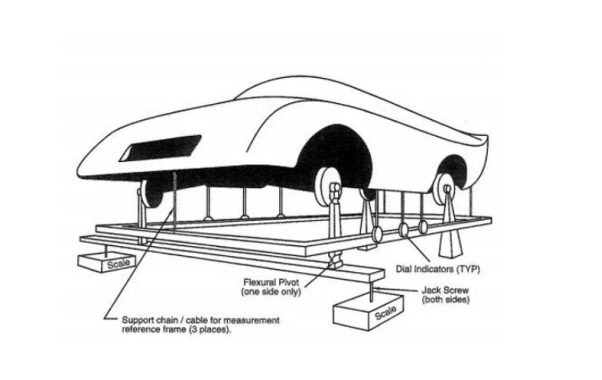

Measuring Chassis Torsional Rigidity

Torsional rigidity can be measured with physical testing or finite elemental analysis (FEA) in chassis. Physical testing uses specialized twist fixtures to apply controlled loads and measure deflection with dial indicators. FEA is a computer simulation method to model loads and analyze chassis deformation.

Design Changes Increasing Chassis Rigidity

Optimized tube dimensions, appropriate material selection and optimize shape in chassis of vehicle increase stiffness with DFM process. These parameters reduce weight and maintain best balance.

What Are the Benefits of a Stiffer Chassis

A stiffer chassis has multiple benefits like:

- Better control in wheel angles by suspension parts and better handling

- High grip to maintain optimal contact with surface

- High safety and durability and reduce flex underload

- Efficient and predictable suspension function.

How to Improve Torsional Rigidity in Design

There are many ways to improve torsional rigidity in design by using closed section (tubes), better cross-section like size or thickness, adding braces, reduced length and material selection with high shear modulus.

In What Applications Is Torsionally Rigid Design Important?

Torsional rigidity is highly important for accuracy in precision machinery like drive shafts, robot joints, cams, and gears. Other than these, aerospace parts like fuselages and wing components, to maintain aerodynamic shape, auto parts, drive shafts and suspension parts, and in civil engineering like bridges, offshore platforms, and tall buildings in which torsional loads from wind or seismic activity are significant.

Change Cross Section Shape

Change in cross sections also changes the torsional rigidity in part. Hollow sections like tube, box or circular shapes have stiffer torsion than a solid part of the same weight. It is because it places material away from the center. While a closed section like box or I-beam has inherent high torsional rigidity than open sections like channels.

Increase Section Size

Torsional rigidity increases by increasing the overall size of cross-sections. It adds weight to the section.

Use Materials with Higher Shear Modulus

Materials with higher shear modulus like steel have higher twisting resistance than lighter materials like aluminum, even though both materials have same dimensions.

Need custom machined parts for your next project? Tuofa CNC machining expert offers one-stop solutions for machining custom parts. Our material selection experts will guide you about the best material for expert design and manufacturing of high-performance parts that need exceptional torsional stiffness.

How Do You Calculate Torsional Rigidity

Torsional rigidity measures resistance to twisting. And there are two commonly used ways to calculate torsional rigidity: physical methods in laboratories or Finite elemental analysis.

Laboratory Torsion Test Methods

To measure torsional rigidity: follow these procedures:

- Measure the length, diameter of specimen.

- Secure the ends of specimen in grips and align the axes.

- Apply incremental torque and record the corresponding angles of twist

- Plot the T vs.θ and find the slope, and use this formula:

Formula: GJ=T·L/θ

T is Applied Torque (N·m), L is Length (m), θ is Angle of twist (radians), G is Shear modulus (Pa or GPa) and J is Polar Moment of Inertia (m4)

Finite Element Analysis for Torsion

FEA is a computational method that splits a complex structure into many small and finite elements. A 3D model of the object is created, and model is then discretized into elements. Materials properties are assigned like shear modulus, fixed supports and loads are applied. And FEM software solves equations for each element to find stress, strain, and twist.

Conclusion

Torsional rigidity in CNC parts varies with the material selection. Select materials with high shear modulus like steel or aluminum, optimize the geometry with large dia and closed sections and reduce length. Finite elemental analysis can validate the design by focusing on increasing polar moment of inertia and minimizing twisting and bending rigidity.

FAQs about Torsional Rigidity

Is higher torsional rigidity better?

Yes, higher torsional rigidity is better because it means less twisting under load.

What is torsional rigidity in cars?

Torsional rigidity in cars is how stiff the chassis is against twisting forces. A higher torsional rigidity means less flex and better steering response.

What are the common units used to measure torsional stiffness?

The most common and easiest unit for torsional stiffness is N·m/rad.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Does Metal Expand When Heated? Understanding Thermal Expansion

Does Metal Expand When Heated? Understanding Thermal Expansion