What is Material Invar? -Properties, Grades, Machining

Aug 19,2025

Aug 19,2025

Maintaining a good dimensional stability is critical in high precision applications. Common materials tend to expand and contract with thermal fluctuations. This thermal expansion or contraction leads to dimensional changes. Now a days, micro meter level dimensional precision is required in critical sectors like aerospace, space exploration and measuring equipment. Only low CTE materials like Invar 36 can be suitable for such applications. Let's learn more about it properties, types and Invar alloy machining.

What Is Material Invar

Material Invar is a low CTE material which shows negligible dimensional changes in response to change in temperature. It is mainly composed of Iron and Nickel. Due to its invariability of dimensions, it is used in mainly in sensitive applications.

Definition of Material Invar

"Invar" is named after the English word "invariable". It is named so because the dimensions of components made from material Invar do not vary with a change in temperature. This unique property exists because of the chemical composition of this alloy. A perfect balance between Nickel and Iron creates this magic.

Brief History of Invar Material

Material Invar was invented by the Swiss physicist Charles Édouard Guillaume in 1896. Due to its uniquely low CTE property, Charles Édouard Guillaume earned a Noble Prize in 1920. Since its invention, material Invar has been extensively used in precision instruments, optical devices and aerospace components.

Why Low Thermal Expansion Matters

Thermal expansion changes dimensions of components as the temperature changes. It can lead to misalignment, measurement errors, or structural stresses. Thus, a low CTE becomes important for dimensionally sensitive components. Material Invar having a CTE of only 1.2 × 10⁻⁶ /°C is considered an excellent choice in for such components.

Common Trade Names and Synonyms

The most common type of Invar alloy contains 36% Nickel. Though there are some variations. Commercially, this alloy is known as "Invar36". Some companies write it as "NILO 36". Another common type is called "Super Invar" which contains an addition of around 4% Cobalt. "Super Invar" has an extra low CTE.

Basics of Material Invar

The brilliance of material Invar lies in its chemical composition and microstructure. It is this precise ratio of Nickel and Iron that bring the low CTE magic. The microstructure and the chemical makeup is responsible its exceptional properties.

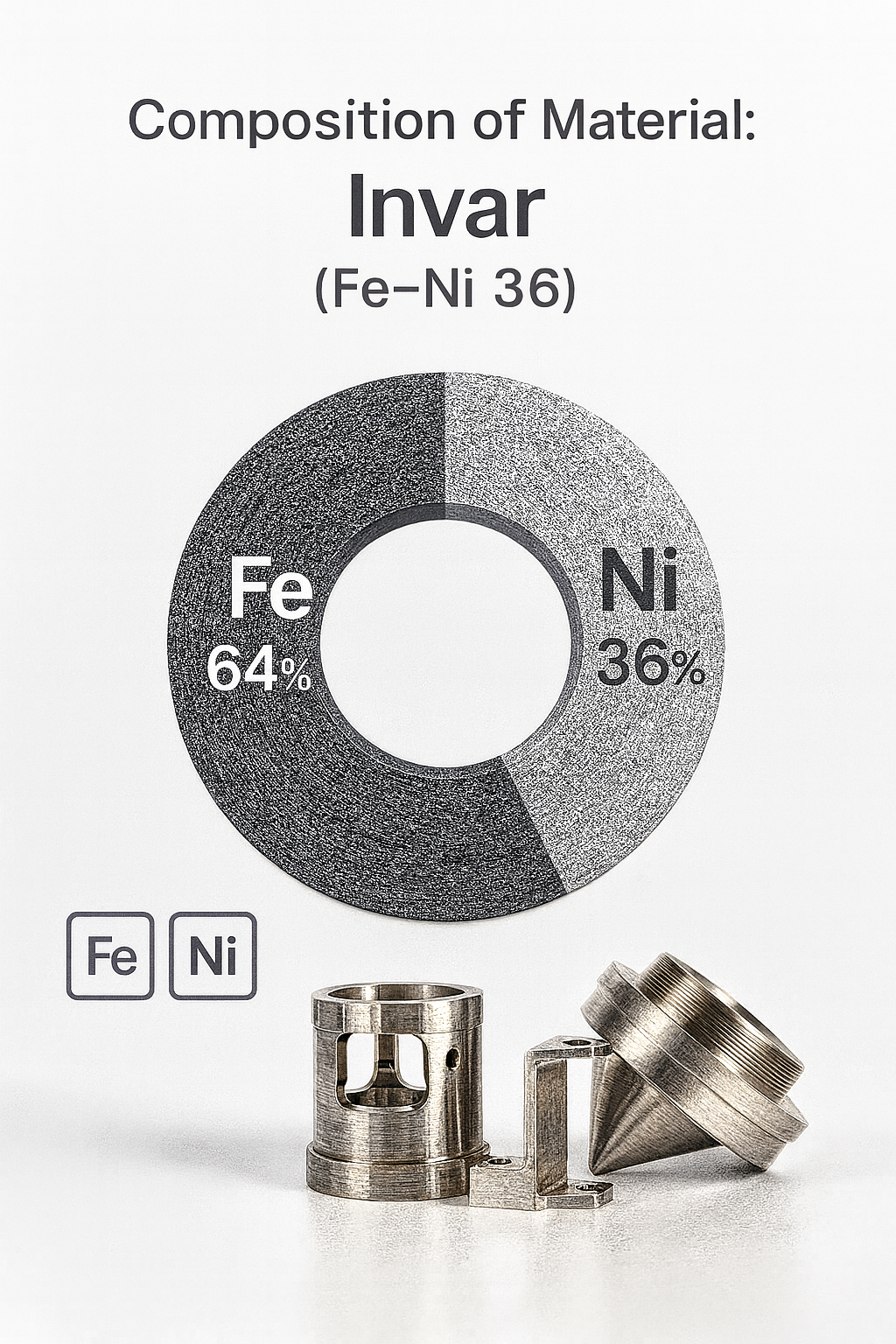

Composition of Material Invar

Material Invar is an Iron-Nickel alloy having 36% Nickel content. A 36% Ni content coincides with the "sweet spot". At this sweet spot thermal expansion becomes invariable. It happens because the thermal expansion is compensated by magnetic contraction in this alloy. Some Invar grades show deviation from this 36% Ni content to attain different properties.

Microstructure and Magnetism

Is Invar material magnetism? Material Invar has a face centered cubic (FCC) austenitic matrix. Below the Curie temperature of 230 °C, it exists in a ferromagnetic state. While the thermal vibrations tend to expand the material, the magnetic ordering exert a contracting force. This effect is called magnetovolume coupling. Therefore, material Invar has a very Low CTE.

Properties of Material Invar

The chemical and mechanical properties of material Invar depend mainly on its chemical composition. Apart from its low CTE property, it possesses various other characteristics as well. As a whole the properties of material Invar are highly suitable for dimensionally sensitive components. Lets sneak a bit into these details.

Invar Chemical Properties

Invar 36 is corrosion resistant in dry environments. But in moist or aggressive environments, it can be prone to corrosion. Material Invar does not possess fully protective corrosion resistant layer, as in the case of stainless steel. However, its corrosion resistance it better than that of mild steel. It is in mid-way between the two. Here is comparison of material Invar with other common materials:

|

Property |

Invar |

Carbon Steel |

Stainless Steel |

Aluminum |

|

Density (g/cm³) |

8.1 |

7.85 |

8 |

2.7 |

|

CTE (×10⁻⁶ /°C) |

1.2 |

11 |

17 |

23 |

|

Tensile Strength (MPa) |

550 |

600 |

480-620 |

300 |

|

Yield Strength (MPa) |

275 |

350 |

300 |

6061-T6: 275 1100-O: 34 |

|

Modulus of Elasticity (GPa) |

145-148 |

210 |

193 |

69 |

|

Brinell Hardness (HB) |

160 |

150 |

180 |

95 |

|

Corrosion Resistance |

Moderate |

Low |

High |

Moderate |

Invar Mechanical Properties

In comparison to steels, material invar is a bit softer and more ductile. Lets talk more about it.

Strength and Hardness

Since material Invar is softer than steel, the yield strength is low. While common mild steels grades yield at around 350 MPa, material Invar starts to yield at only 275 MPa.

Stiffness and Deflection

The modulus of elasticity of Invar 36 is way lower than steels. It has a modulus of elasticity of only 140 GPa. It means that Invar 36 will start to deflect at lower loads. It is mainly regarded for its low CTE and not stiffness. So, designers keep it in consideration.

Common Grades of Invar and CNC Materials

Invar 36 and other common Fe-Ni alloys show low CTE. In some applications a CTE value as low as possible is desirable. While in other application the CTE must match that of the encasing materials like glass. So, the chemical composition of the alloys is tailored such as to meet the requirements of the applications.

Invar, Inovco, and FeNi42

Inovo and FeNi42 also belong to the Fe-Ni alloy system. In comparison to Invar 36, Inovco and FeNi42 have different chemical composition and different expansion behavior. While Invar 36 maintains a very low CTE at room temperature, Inovco has controlled CTE. This makes expansion predictable. FeNi42 has a CTE match certain ceramics and glass. So, this makes it compatible with the adjacent materials.

What is Invar 36 (UNS K93600)

Invar 36 is a commercial grade compliant with the UNS K93600 standard. It has a 36% Nickel content and around 64% Iron content. It has a very low CTE that can be maintained in a wide temperature range of -100 °C to +200 °C.

Invar 36 vs Invar 42

Owing to the difference in the Nickel content, Invar 36 and Invar 42 show different properties.

CTE, Strength, Resistivity Differences

The below table gives a comparison of properties of Invar 36 and Invar 42:

|

Property |

Invar 36 |

Invar 42 |

|

Nickel Content (%) |

36 |

42 |

|

CTE (×10⁻⁶ /°C) |

1.2 |

5.3 |

|

Tensile Strength (MPa) |

550 |

620 |

|

Yield Strength (MPa) |

275 |

310 |

|

Electrical Resistivity (µΩ·cm) |

78 |

80 |

Super Invar vs Invar 36

In comparison to Invar 36, Super Invar show an impressively low CTE. The value of CTE for Super Invar is almost a fourth that of Invar 36. It is a 0.3 × 10⁻⁶ /°C versus 1.2 × 10⁻⁶ /°C respectively. So, Super Invar is used mainly in ultra high precision equipment and tools. But there are also limitations. Super Invar maintains the low CTE in a narrow temperature range (not above 65 oC). It is also a bit difficult to machine.

Invar vs Kovar and Stainless Steel

While Kovar and stainless steels are also Fe-Ni alloys, they serve completely different purposes. Owing to the good adhesion of Kovar to glasses, it is mainly used in glass to metal seals. Kovar has a CTE comparable to glasses. On the other hand 300-series stainless steels are mainly regarded for their excellent corrosion resistance. In short, the main use of Kovar is in coupling with glasses and the main function of stainless steel is corrosion resistance.

Where Material Invar Is Used

Owing to its remarkably low CTE over a wide temperature range, Invar is a material of choice in many applications. It is extensively used in high precision and critical sectors. It offers low risk of warpage, deflection and change in dimensions with temperature fluctuations.

Optical and Imaging Systems

Now a days, optical and imaging systems require greater accuracy and higher resolutions. In scientific research, even microscopic dimensional changes can distort focus or alignment. So, telescopes, lenses, laser systems, and satellite imaging instruments should optical paths that remain stable. Material Invar with its low CTE offers just that. Changes in temperature do not significantly affect its dimensions.

Aerospace and Aviation Structures

To maintain functionality aerospace structures must retain precise dimensions. While material Invar itself maintains dimensions it also helps other materials to do that. As an example. carbon fiber composites are cured in Invar 36 molds. During the curing process, do distortion in geometry occurs with changes in temperature.

Precision Measurement and Scientific Equipment

Material invar is used in devices like interferometers, CMMs and balances. Material maintains the dimensions and geometry of critical components. Thus accuracy and precision can be maintained.

What are Better Alternatives to Invar

Although, material Invar offers some exceptional properties, but in some situations, Invar may not the best choice. There may be some other considerations like predictable expansion profile, corrosion resistance, cost and availability. Kovar and stainless steel are two other materials with some unique functions. Let's discuss it more.

Kovar for Thermal Expansion Matching

Kovar is Fe-Ni-Co alloy having around 29% Ni, 17%Co and rest Fe. As opposed to Invar which show negligible expansion, Kovar expands but in a controlled manner. Its CTE matches that of borosilicate glass. So, it is an ideal mounting material for glasses and ceramics. It expands proportionally with glass. Thus, it minimizes thermal stresses and cracking in such assesblies.

Stainless Steel 440C for High Strength and Stability

Stainless steel 440C is prized mainly for its excellent corrosion resistance and strength. In applications where corrosion resistance weighs more than low CTE, Stainless steel 440C is might be selected.

When to Use an Alternative Instead of Invar

Invar is mainly known as a low CTE material. But, there are many applications where low CTE is not a necessary characteristic. There can be other factors like strength, corrosion resistance, machinability, cost etc. So, based on the requirements of a specific application, a material is selected.

CNC Machining Material Invar Alloy

Material Invar has a moderate strength and it is comparatively softer than steel. But still Invar material tough to CNC machine. It is prone to work harden under excessive force on tool. Due to its low thermal conductivity, heat can easily build up during machining. So, there must be a stringent process control to cope with these issues.

CNC Milling Invar

In order to avoid work hardening high feed rates with shallow depths of cut are preferred. Ceramic or carbide tools with sharp cutting edges should be used. To prevent heat buildup a generous flood cooling should be employed.

CNC Turning Invar

Material Invar tend to form long and stringy chip. It can pose a major challenge in Invar alloy machining. Chip breakers can help. Use carbide inserts with positive rake angle to avoid long chips. A constant feed can avoid tool dwell. Thus heat build up can be mitigated.

CNC Drilling Invar

Since Invar is ductile, chip evacuation can be an issue in drilling. Peck drilling cycle can be helpful in evacuating chips and heat buildup. Cobalt HSS or carbide drills show a good wear resistance in high demanding applications.

Low CTE Material Machining Tips

Plating and Coatings for Protection

The as-machined surface might need a coating layer to improve aesthetics and corrosion resistance. Nickel plating, passivation, and paint are three common methods. Passivation provides an oxide cover with minimal dimensional change. Nickel plating and paint systems have a more appealing look but dimensions of parts might be changed. So, an allowance in CNC machining should be incorporated for the thickness of these additional layers.

Heat Treatment for Dimensional Stability in Material Invar

Maintaining dimensional stability in material Invar is pertinent as it is used mainly in dimensionally sensitive applications. Internal stresses build up during CNC machining or casting etc. can influence dimensional changes. To maintain stable dimensions, material invar is subjected to heat treatment to diminish internal stresses.

Annealing

Material Invar is kept at around 8500C and then furnace cooled. Residence time in furnace is determined by the dimensions of the parts. Annealing changes the microstructure such that all internal stresses are relieved and ductility is restored. It also helps in subsequent shaping operations.

Stress Relief

Stress relieving is done at temperatures lower than full annealing temperature. The main object is to relieve internal stress. A temperature range of 300-6000C is sufficient for this purpose.

Stabilizing Ageing

Material Invar can undergo phase transformations over a long time. So, there is a risk of dimensional changes during the service life. Ageing treatment is thus given to accelerate the phase transformation process. So, all phase transformation that may happen during the service life occur before putting the parts in service.

Why Machining Material Invar Is Expensive

Invar alloy CNC machining is comparatively more expensive than other common materials. Several factors add up to the cost. Invar is costly and its machining process is a bit difficult. But, still, the near zero expansion behavior makes it worth it.

High Price of Raw Invar

Invar 36 has around 36% Nickel content. Nickel has been an expensive metal since a long time. Newer applications of Nickel like battery cathodes for EVs has risen its demand significantly. As a result, the price Nickel has been ever-rising. So, material Invar seems to be an expensive material in the long term.

Difficult to Machine

Owing to its work hardenability during machining and low thermal conductivity there are several challenges in Invar alloy CNC machining. The toughness of material invar results in built-up edges and long chips. As a results machinists have to adopt slower feed rates, lighter cuts, and frequent tool changes. High scrap generation, frequent tool changes and slower machining rises up the cost.

Fast Tool Wear

Due to high toughness of material Invar tool wears out quickly. Expensive carbide tools have to the used. That too wear out quickly.

Conclusion

Material Invar is a highly valuable low CTE material for manufacturers of high precision equipment. Due to its near zero thermal expansion, it provides an excellent dimensional stability. But there are certain challenges in machining accurate parts out of material Invar. Due to its high cost generation of any defective parts is detrimental. So, suppliers of these components need to be absolutely professional.

TUOFA CNC Machining is one such name. We at TUOFA CNC Machining provide custom Invar materials machining services. Our dedicated machining team ensures that the components meet all the desired specifications.

FAQs on Material Invar

Why is Invar so expensive

Invar is expensive because of the high Nickel content. Nickel has been an expensive metal and its price has been ever-rising.

Is Invar difficult to machine

Yes. The high toughness, low thermal conductivity and work hardenability pose several challenges.

What metal has the least thermal expansion

Super Invar has a impressively low CTE of only 0.3 x 10-6/ oC.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What is DC01 Steel? -Properties, Machining, Comparison

What is DC01 Steel? -Properties, Machining, Comparison