Fatigue Limit: Understanding Material Durability

Dec 03,2025

Dec 03,2025

The most important feature to consider when selecting the material is the service conditions of the application. These are determined by identifying fatigue limit of material like how much load a material can withstand before failure or by identifying load magnitude or direction (regular, irregular) etc. This article will explore all the essential details about the fatigue limit of material and how to avoid failure from this.

What Is Fatigue Limit?

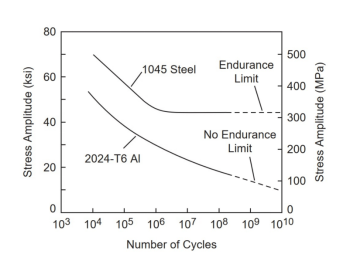

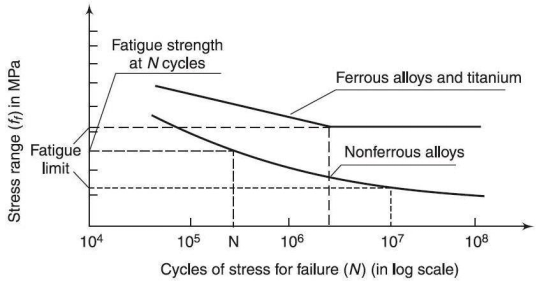

It refers to the maximum value of stress a material can withstand for a countless number of cycles without failure. It is also called the endurance limit and is an important property for designing bridges and aircraft. Certain materials like ferrous alloys have a defined fatigue limit.

Fatigue Limit vs Fatigue Strength: What Are the Differences?

Fatigue limit and strength are different properties. Fatigue strength can be applied to all materials. But fatigue limit is only for certain materials. Major difference between them is explained below

What Is Fatigue Strength?

It is the maximum stress level a material can handle for a definite number of load cycles before failure. It is used for materials that have no fatigue limit such as non-ferrous metal. For example, aluminum fatigue strength is specified as 108 cycles.

Differences between Fatigue Limit and Fatigue Strength

The differences between these terminologies are as:

|

Features |

Fatigue Strength |

Fatigue Limit |

|---|---|---|

|

Definition |

Maximum stress for finite cycles |

Maximum stress for infinite cycles |

|

Material |

All materials |

Only certain materials (steel) |

|

Example |

Stress aluminum can withstand for 10 8 cycles |

The highest stress level steel bears to an infinite number of cycles |

What Materials Have a Fatigue Limit?

All engineering materials have different responses towards fatigue limits. Alloys like steel 4140 and 4340 have a clear fatigue limit. This limit is influenced by factors like chemical composition and heat treatment. However, not all materials show this reaction. For example, non-ferrous metals have no true fatigue limit and can eventually fail under repeated loading.

Metals with Fatigue Limits

Some metals, like ferrous metals, have a true fatigue limit. This fatigue limit is affected by its chemical composition and heat treatment. The section below explains what ferrous materials have fatigue limit to provide a clear understanding of metal's behavior under cyclic loading.

Some Ferrous Metals:

1.Low Carbon Steel has moderate fatigue resistance with a fatigue limit between 140 and 210 MPa.

2.Medium Carbon Steel has a fatigue limit. But its fatigue life can be highly affected by factors like surface roughness.

3.High Carbon Steel has fatigue limit. However, its exact value depends on its specific composition, heat treatment, and surface finish.

4.Alloy Steels have high fatigue limit due to alloying elements. Its resistance can vary depending on the specific grade like 4140 and 4340 and its environment.

5.Stainless Steel has a fatigue limit. AISI 304 and AISI 316 are commonly used stainless steel in many industries.

6.Cast Steel has lower fatigue limit than wrought steel due to the presence of internal defects and lower ductility.

|

Metals |

Fatigue Limit Range |

|---|---|

|

Low Carbon Steel |

140-210MPa |

|

Medium Carbon Steel |

200-300MPa |

|

High Carbon Steel |

300-600MPa |

|

Alloy Steel (4140) |

350-600MPa |

|

Alloy Steel (4340) |

450-700MPa |

|

Stainless Steel (304) |

200-300MPa |

|

Cast Steel |

100-250MPa |

Metals without Clear Fatigue Limits

It is obvious from the previous section that many ferrous metals have a true fatigue limit. This helps engineers to choose materials that are durable and have high performance under cyclic stress.

However, different from ferrous metals, non-ferrous metals like aluminum, copper or magnesium generally do not have a true fatigue limit. Instead, their fatigue behavior is defined by their fatigue strength. With enough repeated loading even at lower stress, these materials will eventually fail

Aluminum & Aluminum Alloys

Does aluminum (Al) have a fatigue limit? The answer is no but some aluminum alloys have good fatigue strength.

1.Pure Al lacks a fatigue limit, and its fatigue resistance is defined by its fatigue strength.

2.6061 Al Alloy has good fatigue strength and is used in heavy-duty vehicles and bridges.

3.2024 Al Alloy has a high fatigue strength and is used for aircraft wings and fuselages.

4.7075 Al Alloy has high fatigue strength and is used in high-stress aerospace applications.

Copper & Copper Alloys

Fatigue limit of copper (Cu) and its Cu alloys are as:

1.Pure Cu has high fatigue strength in the half-hard or annealed state

2.Brass and bronze fatigue resistance is characterized by fatigue strength. And it varies depending on the specific alloy and its treatment.

Magnesium Alloys

They do not have a distinct fatigue limit. Their behavior is analyzed using fatigue strength, fatigue life, and other related properties.

Titanium Alloys

These are used in aerospace applications because of their high fatigue strength. They are commonly undergone to fatigue testing to determine their fatigue strength.

Do Plastics Have Fatigue Limits?

No, they do not have fatigue limit. Because they do not typically show a clear "knee" in their stress-life (S-N) curves.

How to Calculate Fatigue Limit

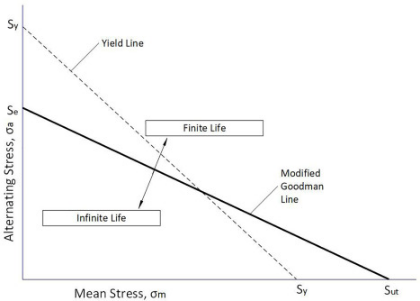

The most common way to calculate fatigue limit is S-N curve which plots stress against the number of cycles to failure. Other ways are empirical formula like one-half of the ultimate tensile strength for some steels, or models like the Goodman formula for combined stress.

Typical Methods for Calculating Fatigue Limit

The testing methods for identifying fatigue limit are:

1.S-N Curve Testing

It is the core physical testing method used to measure the limit with standards like ASTM E466 and ISO 1099. Multiple identical specimens are subjected to various levels of cyclic stress until failure. The number of cycles to failure (N) at a given stress amplitude (S) is plotted on a graph to create the S-N curve.

2.Empirical Formulas

These are quick methods, and these formulas use various modification factors for real-world variables like surface finish, size, temperature, to measure fatigue limit.

3.Goodman

The Goodman diagram is a linear or parabolic relationship boundary of mean stress versus alternating stress to give safe operating limits.

4.Fatigue Data Tables

Handbooks and databases are used to provide data of established fatigue properties and limits for common engineering materials.

5.Finite Element Analysis (FEA)

FEA is a simulation technique used in computational engineering. It predicts a material reaction to various physical forces like cyclical loading. This is the most common method used in CNC Machining to optimize the design of parts and determine the best solution for manufacturing.

What Factors Affect Fatigue Limit?

Some common factors that affect the fatigue limit are as:

Properties of Materials

This includes microstructural and compositional properties, mechanical properties and material type like ferrous or non-ferrous metal. Purity or presence of inclusion decreases fatigue strength. Similarly high tensile strength increases fatigue strength in material

Environmental Factors

Environmental factors such as corrosion, temperature, humidity, chemical exposure, and radiation can affect a material's fatigue limit. Corrosion and high temperatures lower the fatigue limit by weakening the material. Chemical exposure and radiation also degrade material properties and reduce fatigue resistance.

Manufacturing Process

Processes like surface finish can reduce cracks and increase fatigue limit. Presence of manufacturing defects like voids, inclusion can increase stress concentration and initiate failure.

Surface Condition

Surface conditions have a significant effect on the fatigue limit of a part. For example, surface roughness, microcracks, and other defects greatly reduce fatigue resistance. A rough or damaged surface creates stress concentration which triggers crack initiation and growth under stress. On the contrary, a smooth surface reduces stress concentration and improves the material's fatigue resistance.

The Role of Fatigue Limit in Applications

Fatigue limit is important for ensuring durability, preventing catastrophic failures, and ensuring safety in fields like aerospace or automotive. Belows is the applications of fatigue limit. Let us learn more details from them.

Aerospace

Fatigue limit is important for parts like aircraft wings, engine parts, and landing gear. Parts designed with fatigue limit allow them to withstand the severities of flight, takeoff, and landing.

Automotive

Suspension systems, engine parts, and drive shafts undergo continuous stress. A high fatigue limit is essential to have longevity and safety of these parts

Industrial Machinery

Gears, shafts, and other moving parts in heavy machinery must work reliably for years under continuous stress which depends on their fatigue limit.

Medical Devices

Implants, prosthetics, and surgical instruments are subjected to constant stress within the human body. They must be durable as a matter of patient safety which depends on their fatigue limit.

How to Improve Fatigue Limit?

The fatigue limit of a part can be improved by focusing on design optimization, selecting appropriate material, and using suitable CNC machining methods.

Optimize Design for Parts

CNC machines can precisely cut and smooth features to remove sharp corners. They act as stress concentrators and are common failure initiation points. This creates a smoother transition of stress throughout the component.

Selecting Right Materials

Materials with high-strength and fine-grained material provide a better foundation for fatigue resistance. This is because of surviving repeated stress without crack growth. For example, alloy steel 4140 and 4340 have refined microstructure and high strength and thus have higher fatigue limit. Similarly, high carbon steels and stainless steels 304 and 316 are stronger and finer-grained structures with high fatigue resistance.

Choose the Best CNC Machining Methods

CNC machining methods like shot peening, laser peening, and cold rolling can enhance the fatigue strength of materials. During CNC machining, factors like cutting speed, feeding rate and cutting depth are important in determining the final surface quality of part. For example, surface roughness, tool marks and microcracks can occur if these parameters are not optimized.

Tuofa CNC milling, CNC turning and cutting services can help you create precision parts. With our well-trained engineering team, we can ensure that your parts are made with high strength and durability.

Select Proper Surface Treatment

Surface treatments are different for high-stress parts, general parts, ductile material and for hard surface parts. Selecting the right surface treatment is critical for improving fatigue limit of machined parts. Common surface treatments are shot peening (to add beneficial stress), anodizing, carburizing and nitriding, nickle and chrome plating and PVD coating. Tuofa can also offer multiple surface treatment methods for you to enhance your machined parts.

Conclusion

Fatigue limit is the maximum stress a material can withstand for an infinite number of loading cycles without failing. It is also called endurance limit. Fatigue limit is important for designing parts for vehicles and machinery, aircraft and medical devices. Ferrous metals have a clear fatigue limit. But non-ferrous like aluminum fails from low stress and are described by their fatigue strength.

Frequently Asked Questions (FAQ)

What is the endurance limit?

It is the same as fatigue limit which is the maximum stress a material can withstand without failing from repeated loading.

Endurance limit vs fatigue limit: are they different?

Yes, fatigue limit and endurance limit are different but often used interchangeably. Fatigue limit is the maximum cyclic stress a material can withstand for an infinite number of cycles. While the endurance limit is a critical property for engineers when designing components. That is subjecting components like aircraft and bridges to cyclical loading over time.

Does aluminum have a fatigue limit?

No, most aluminum alloys do not have a true fatigue limit.

Does carbon fiber have a fatigue limit?

No, carbon fiber does not have a fatigue limit.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

CuZn38Pb2 Brass: Composition, Properties, Machining

CuZn38Pb2 Brass: Composition, Properties, Machining