Aluminum Block Machining: Guide for CNC Milling Projects

Feb 18,2026

Feb 18,2026

CNC milling always been a highly reliable solution when it comes to precision, repeatability and accuracy. Aluminum block machining is being widely used to manufacture parts like engine blocks. The stringent tolerance and dimensional accuracy requirements make no process other than CNC milling to be suitable. There is no space for a margin of error. Even a slight deviation can lead to a big difference in performance and functionality. Aluminum engine block is only one example. There are a lot of other applications as well. Lets discuss this topic in detail.

What Is Aluminum Block Machining?

Aluminum block machining is a commonly used process to make parts out of solid raw stock like blocks or billets. It employs CNC machining operations like milling, boring, tapping, drilling and turning. Aluminum is relatively softer and more thermally conductive than steel which makes it highly machinable. Parts machined out of block of aluminum are thus expected to give tight tolerances and precise dimensions.

What Is an Aluminum Block?

Aluminum block commonly refers to the raw stock from which precision components can be CNC machined. Solid block of aluminum is used to manufacture products like mounting bases, mounting blocks, machine fixtures, housings and brackets. In a more specific context, auto industry people often used the term aluminum blocks for aluminum engine block that are made up of aluminum. Aluminum block machining carves out cavities and passages for cylinders, crankshaft, oil and coolant.

Machining Solid Aluminum Blocks and Billets

Aluminum block machining uses techniques like CNC milling, drilling, boring and tapping to produce parts of the desired geometry. Quite often a rough machining cycle is first opted to make net near shape. Then finishing passes bring the part to the precise dimensions. Aluminum billet is often preferred in high quality applications. Billets usually have fewer casting defects than blocks. Tool selection, cutting parameters, fixturing and chip evacuation mechanism are a bit different in case of aluminum.

When to Use Aluminum Blocks for CNC Parts

Aluminum blocks are regarded for their uniform properties across the entire cross section. They reduce the number of components in assembly, thus providing a more rugged structure. CNC machining maintains precise dimensions and tight tolerances. On the downside, a few alloys are a bit challenging to machine. But, don’t worry, specialized machining centers like Tuofa can quality standards a way ahead of your expectations.

Aluminum Prototyping Parts

CNC machining is an ideal choice for prototyping parts. In comparison to steel or cast iron, aluminum is expensive. Before opting for mass production processes like casting or extrusion, employing aluminum block machining is a smart choice. It enables to test fit, form, and function before mass production. Design reiteration can be easily implemented. Once the design is tried and tested, there is always a room for scaling up production.

Structural Parts

Aluminum block machining can be adopted to manufacture parts with good stiffness and dimensional stability. CNC processes are commonly used to produce structural parts like aluminum bases, plates and frames. Machining from a solid block of aluminum ensures uniform material strength, precise flatness and accurate hole alignment.

Engine Blocks and Housings

Aluminum engine block is well recognized for its low weight and high fuel efficiency. In automotive applications, engine blocks, gearbox housings, pump bodies and compressor housings can be made of aluminum alloys. The biggest advantages of CNC milling are:

- Carving out complex internal features

- Maintaining tight tolerances

- smooth sealing surfaces

Custom Parts

CNC machining is adoptable for any scale of manufacturing. Be it a single piece or a million pieces, CNC machining remains relevant. Blocks of aluminum are used to make custom parts like brackets, adapters, enclosures and manifolds. It gives a lot of design freedom. Fast turnaround and consistent quality given by CNC is highly appreciated by customers.

Types of Aluminum Blocks for CNC Milling

There a few types of aluminum blocks for aluminum machining application. Each type is identified as a unique grade. These aluminum grades provide a combination of strength, machinability, corrosion resistance and cost. While selecting a certain block of aluminum for milling, these factors are considered. The below table draws a comparison of these common types of aluminum blocks.

|

Aluminum block grade |

Machinability |

Corrosion Resistance |

Mechanical Strength |

Hardenability |

Key features |

|

6061 |

Excellent |

Good to excellent |

Medium |

Heat-treatable |

Balanced strength and corrosion-resistant |

|

7075 |

Very Good |

Fair |

Very High |

Heat-treatable |

Very high strength |

|

2024 |

Good |

Poor- Fair |

High |

Heat-treatable |

High fatigue strength |

|

5052 |

Good |

Excellent |

Low- Medium |

Not heat-treatable |

Excellent corrosion resistance |

|

5083 |

Fair -Good |

Excellent |

Medium |

Not heat-treatable |

Strong marine grade alloy |

|

MIC 6 |

Excellent |

Good |

Low- Medium |

Not heat-treatable |

Flatness |

6061 Aluminum Blocks for Machining

6061 aluminum is the most widely used grade for CNC machining. Alloying additions like magnesium and silicon are present in this alloy. When a T6 type heat treatment is given to, it forms Mg2Si precipitates that enhance hardness and strength. This heat treated 6061 aluminum is suffixed by ‘T6’, commonly denoted as 6061-T6. An excellent balance of strength, machinability, corrosion resistance and weldability make 6061 aluminum blocks versatile for a lot of applications.

7075 Aluminum Blocks for Parts

7075 grade block of aluminum is the strongest among all aluminum alloys. Their strength level matches that of steel. This high strength coupled with low density makes it ideal for aerospace applications. On the downside, it is a bit more expensive and has lower corrosion resistance. But its high machinability enables to make complex parts to be made by aluminum block machining.

2024 Aluminum for Blocks

2024 is another structural grade. 2024 aluminum blocks has high strength and fatigue resistance. It makes it suitable for applications that require repeated loading. But it has a higher susceptibility to corrode. So, some protective coatings may be required.

5052/5083 Aluminum Blocks

These blocks of aluminum have an impressively high corrosion resistance. Even in marine environments and aggressive chemicals, 5052 grade behaves well. Moreover, it offers a good strength even in non heat treated condition. As a result, aluminum block machining of 5052/5083 grades is done for components intended to be used in marine environments.

MIC 6 Aluminum

MIC 6 is basically a cast aluminum tooling plate with a proprietary composition. It is known for its excellent flatness. MIC 6 is manufactured using aluminum block machining. It is then stress relieved. MIC6 tooling plate is commonly used in jigs, fixtures, machine tables and inspection fixtures.

CNC Processes for Aluminum Block Machining

Aluminum block for milling, turning, and tapping are common choices in high demand manufacturing. Below we are going to talk in details:

Rough Milling Process

This is the most aggressive stage in aluminum block machining. Most of the material is removed in this stage at a high speed. The machined block is given a net near shape which features major cavities. As an example, in rough milling of aluminum engine block, deep pockets for cylinder are made in this stage. Tight tolerances are then established latter on in the finishing stage.

Precision Machining Process

For developing a better understanding let’s consider the example of aluminum engine block.

- Drilling Block:It creates oil passages, coolant channels, bolt holes, and fastener locations.

- Boring Block: It ensures tight tolerance for cylinder bores.

- Tapping Block:It creates internal threads for fasteners

What Is The Best Way to Cut Aluminum Blocks?

The best way of aluminum block machining is the one which minimizes tool wear, increases productivity, reduces built up edges and improves surface finish. This can be achieved by optimizing parameters, ensuring chip evacuation and proper cooling.

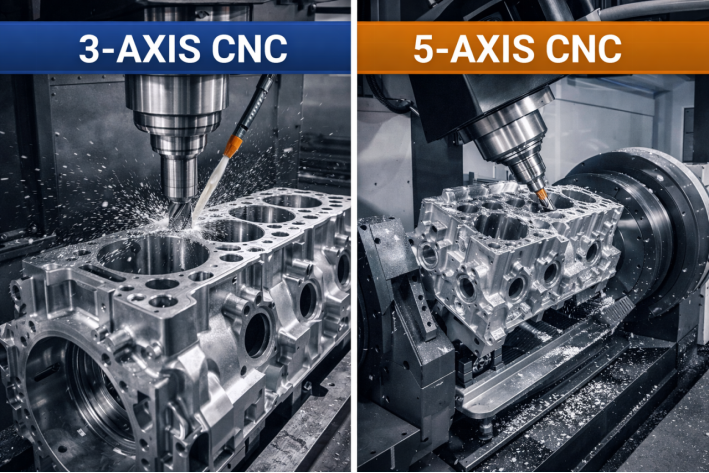

3 Axis vs 5 Axis Milling on Aluminum Blocks

All CNC axes types are relevant when it comes to aluminum block machining. But the real consideration is on part complexity, cost and productivity. The below table compares 3 axis milling, 4 axis milling and 5 axis milling.

|

Aspect |

3 -Axis Milling |

4- Axis Milling |

5-Axis Milling |

|

Axis Movement |

X, Y, Z |

X, Y, Z + rotation |

X, Y, Z and dual rotation |

|

Part Complexity |

Simple to moderate |

Moderate |

High to very complex |

|

Setup Count |

Multiple reclampings |

Reduced setups |

Single |

|

Feature access |

Vertical features only |

Multiple faces |

Full multi angle access |

|

Accuracy |

Good |

Very good |

Excellent |

|

Cycle Time |

Longer for complex blocks |

Shorter than 3-axis milling |

Shortest for complex parts |

|

Cost Level |

Low |

Medium |

High |

3 Axis Milling Aluminum Blocks

This type of milling is really cost efficient and precise for simpler parts. Tool has the freedom to move along X,Y and Z axes.

4 Axis Milling Aluminum Blocks

4 axis milling gives an addition rotary axis. So, it can handle a bigger level of intricacy than 3 axis milling. It is a bit more expansive. But the reduces setups justifies the additional cost.

5 Axis Milling Aluminum Blocks

5 axis milling is by far the most efficient process for complex parts like aluminum engine block. Tool has a lot of freedom to move as per CAD requirements. But, it is the most expensive among all of the 3 processes.

Aluminum Engine Block Machining Basics

Why CNC Machining Matters in Engine Block?

CNC machining matters a lot in engine block manufacturing. Engine blocks require a very strict dimensional control within tight tolerances. Even small deviations can lead to oil leakage, poor combustion efficiency, vibration, or premature wear. On the other hand, some features have a high level of complexity. Processes other than CNC machining cannot reliably make features like cylinder bores, deck surfaces, oil galleries, coolant passages and mounting interfaces.

Benefits of Precision CNC Milling

- High accuracy

- Repeatability

- Excellent surface finish,

- Complex geometry

- Reduced human error

- Scalability

How to Machine Aluminum Engine Blocks?

Aluminum blocks are at first rough machined to quickly remove excessive material. Then finishing operations like drilling for oil and coolant passages, boring cylinder bores and milling deck surfaces are done.

How Hard Is It to Machine Aluminum Blocks?

Aluminum is relatively easier to machine due to low hardness and high thermal conductivity. But for geometries as complex as engine block, it can be a bit challenging. Engine blocks have very stringent requirements for dimensional control. Further, the presence of difficult to machine features like thin walls and deep pocket make it more difficult. It is up to the expertise of the CNC machining factory to deliver accurate dimensions.

Surface Treatment and Functions

Surface treatment is usually provided to the machine blocks while considering their operating environments. As an example, anodization increases wear resistance and adds beautification to the parts. On the other hand, protective coatings like Nikasil is solely meant for corrosion protection. Sometimes, shot peening is done to increase fatigue resistance of the parts.

Design Tips for Machined Aluminum Blocks

The reliability of machined blocks lies greatly on the design. A good design helps in improving manufacturability while reducing unwanted defects. This section gives some DFM suggestions for CNC beginners.

Aluminum Grades Selection

Aluminum grade selection plays a key role in achieving desirable results from aluminum block machining. As already discussed, 6061 is the most common grade for such applications. In case a very high level of mechanical strength is needed 7075 grade is the answer. If the components are to used in aggressive chemical environments, then 5052 grade is the best to be used. There are various other grades having their own key strengths. A product developer needs to think from all aspects.

Functions and Features Design

A robust design helps in achieving high production rate with minimum manufacturing defects. Due diligence in CAD should be made to improve manufacturability. As an example, thin walls tend to distort the shape during machining. So at least 2-3mm of wall thickness for small components should be given. Use of standard hole sizes prevent the need to custom drill bits. Maintain symmetry in design helps in reduction of internal stresses. Add internal fillets avoids sharp edges. Following these general principles helps in getting a good design.

Machining Tools

The use of a sharp milling cutter is always preferred for CNC milling. Carbide tools give a high level of hardness that reduces their wear and prolongs their life. 2 or 3 flutes helps in better chip evacuation.

What’s 1 lb of Aluminum Worth?

A correct estimation of the cost of material guides in choosing thee right grade and the right quantity. In bulk orders even a few cents make a big difference. It is recommended to take quotations from multiple suppliers for your project. All materials are not exactly the same. Be cautious to compare qualities of materials being offered.

How Much Is 6061 Aluminum Per Pound?

Determining the cost of Block of Aluminum for CNC is subjective. It depends on the country of origin, dimensions and MOQ. As an example, the price of an American made block with similar specs may differ from a Chinese made aluminum block of similar specs. As a rough idea, the price per pound ranges from USD 2 – USD 6 depending on ordering quantity and origin.

How to Choose the Right Aluminum Block

Before placing an order, consider the following factors:

- Grade

- Dimensions

- Ordering quantity

- Supplier type: retailer or mill

How Much Does Aluminum Block Machining Cost?

Determination of machining cost depends on the complexity of design, number of parts, grade of material and requisition of any additional services. We at Tuofa CNC Machining give expert advice and estimations free of cost. Just send us the CAD file. Our team will work on feasibility and give some DFM suggestions. Turnkey manufacturers are encouraged to contact us. We provide all sorts of machining processes and surface treatments.

Get a Free Quote from Tuofa

Please feel free to send us your CAD file on our email address: info@tuofa-cncmachining.com Our team would follow up your case.

Factors for Aluminum Block Parts Price

Machining cost varies depending on factors like:

- Material selection

- Complexity offeatures

- Tolerances: As an example, IT5tolerance is very high (0.01mm). Whereas, IT6 tolerance is high but lower than IT5 (around 0.02mm)

How to Choose Surface Treatment

Surface treatments is basically required for three purposes:

- corrosion resistance

- wear resistance

- beautification

As an example, 2024 aluminum might need a corrosion protective Nikalsi coating. Whereas, 5052 grade might need hard anodization for some wear resistant application.

How to Calculate the Cost?

For a rough estimation add the cost of each step. Start with procurement of material and then add shipping fee, taxes, machining costs, designing costs and any surface treatment cost. You would get a rough estimation. For an accurate quotation, feel free to contact Toufa. We would give a quotation for free.

Conclusion

Considering the versatility of aluminum, CNC machining of aluminum blocks is quite relevant. The most common application of aluminum block machining is manufacturing of aluminum engine blocks. CNC machining is capable of handling a high level of design complexity. But certain factors need consideration to make durable products. Grade selection and surface treatment biggest factors.

FAQs

What is the best aluminum block for CNC milling?

The most widely used grade is 6061 for aluminum block machining. Other grades are also important depending on the applications.

How much does it cost to get aluminum machined?

The cost of machining varies depending on factors like design complexity, ordering quantity and grade of material.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Vapor Polishing: An Important Guide to Plastic Parts

Vapor Polishing: An Important Guide to Plastic Parts