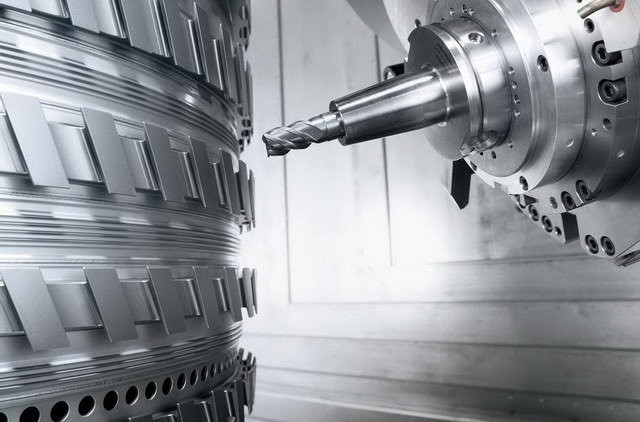

Gear Manufacturer from China, OEM Custom CNC Machining Parts

Our clients rely on Tuofa CNC Machining "high-speed" capabilities to service their rapidly-evolving industries for contract manufacturing needs. Buyers can count on our talented team to provide precision, expertise, technology, and the highest caliber of customer service. Our in-house engineering analysis, precision inspection, and quality control services ensure the dependability of our products. Tuofa is the custom CNC machining parts supplier that you need.

- Get a free quote within 12 hours

- 50+ metals and plastics, 10+ surface finishes

- Machined prototypes in as fast as 1 day

- Tolerances down to ±0.0004" (0.01mm)

- Custom design depending on customer specs

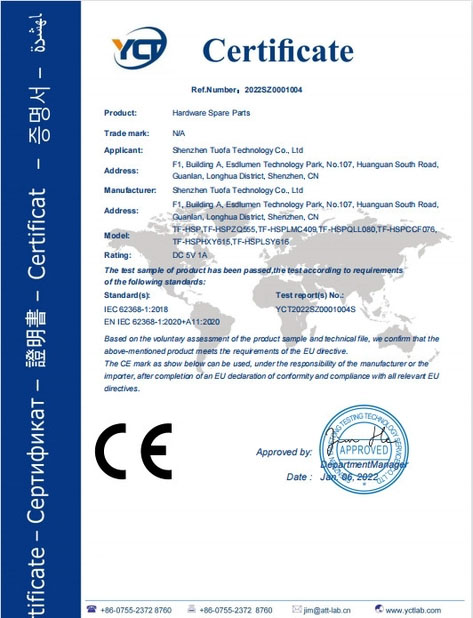

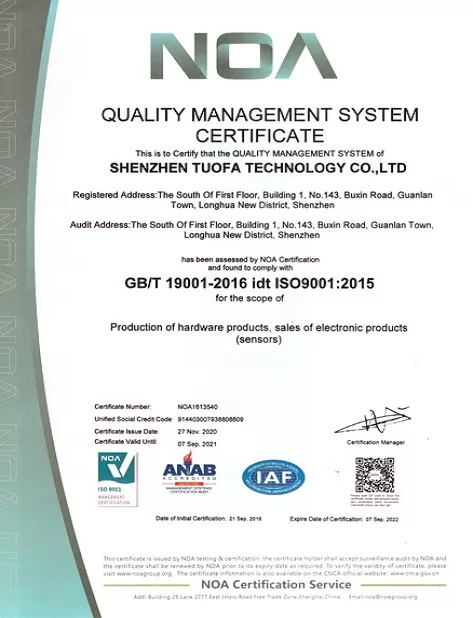

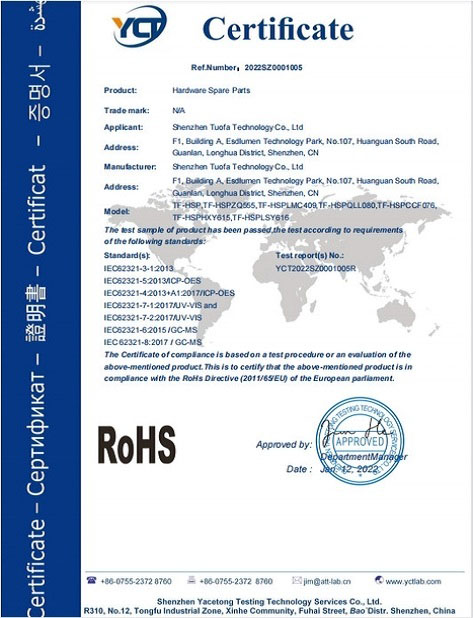

- ISO9001:2015, ROHS:2011/65/EU,CE certification

Online Gear Manufacturing Service - Low-Cost On-Demand Manufacturing

At Tuofa, our entire team takes pride in supporting the growth of Global manufacturing by producing nothing but the highest quality products providing the service and competitive pricing that exceeds our customers’ expectations.

Gear Manufacturing Company – Gear Machining & Custom Gear Production

With years of experience in CNC manufacturing and metal machining, Tuofa has the expertise to produce custom CNC machined parts online with various gear manufacturing processes and techniques. From gear designs to production to shipping, we can meet your requirements at each stage. Our capabilities including gear machining (gear cutting, gear hobbing, gear milling, gear grinding) and gear forming (gear forging, gear extrusion, gear casting, gear injection molding), the cutting edge technologies, and advanced gear manufacturing equipment at our factory enables our gear products to achieve the industry-leading standards or exceed the customers’ expectations. Whether you want to find the manufacturers of spur gears, helical gears, spiral bevels, or other types of CNC gears, we’ll deliver top-quality products with a fast turnaround. From hard metals to plastics, a wide selection of materials with excellent properties are provided. We can also help you in the design and review of almost all types of gears to enhance their functionality and manufacturability

Why Choose Tuofa Gear Manufacturing?

- Custom solutions for complex gear manufacturing tasks and technical support

- Well-equipped facilities, seasoned workforce, and heavy investment in gear development

- The right expertise and multiple techniques for the production of different types of gears

- Prototypes can be developed and evaluated to improve manufacturing and performance

- Quality inspection services to ensure right dimensions and minimal quality issues

- Work closely with customers to get the most customer satisfied results

What Is Gear Manufacturing?

Gear manufacturing refers to the making of gears. Gears can be manufactured by a variety of processes, including casting, forging, extrusion, powder metallurgy, and blanking. As a general rule, however, machining is applied to achieve the final dimensions, shape, and surface finish in the gear.

Types of Gear Manufacturing Process

The selection of gear manufacturing process is depending on the application, accuracy requirements, and other actual situations. The gear manufacturing processes are mainly divided into two categories: gear machining and gear forming.

Gear Manufacturing Processes

There are multiple ways in which gear blanks can be shaped through the cutting and finishing processes.

Gear Forming

In gear form cutting, the cutting edge of the cutting tool has a shape identical to the shape of the space between the gear teeth. Two machining operations, milling and broaching can be employed to form cut gear teeth.

Form Milling

In form milling, the cutter called a form cutter travels axially along the length of the gear tooth at the appropriate depth to produce the gear tooth. After each tooth is cut, the cutter is withdrawn, the gear blank is rotated, and the cutter proceeds to cut another tooth. The process continues until all teeth are cut

Broaching

Broaching can also be used to produce gear teeth and is particularly applicable to internal teeth. The process is rapid and produces a fine surface finish with high dimensional accuracy. However, because broaches are expensive and a separate broach is required for each size of gear, this method is suitable mainly for high-quality production.

Gear Hobbing

Gear hobbing is a machining process in which gear teeth are progressively generated by a series of cuts with a helical cutting tool. All motions in hobbing are rotary, and the hob and gear blank rotate continuously as in two gears meshing until all teeth are cut.

Gear Generation

In gear generation, the tooth flanks are obtained as an outline of the subsequent positions of the cutter, which resembles in shape the mating gear in the gear pair. There are two machining processes employed shaping and milling. There are several modifications of these processes for different cutting tools.

Our Gear Manufacturer Experience in Numbers

|

|

|

|

| 2000+ | 50000+ | 60+ | 15+ |

| Companies served | CNC parts produced | Countries shipped | Years in business |

Just in Time and Right on Time Every Time

Tuofa is your OEM partner for high quality parts delivered on time and right when you need them. We support just-in-time / lean manufacturing practices so your production line will be as efficient as possible.

Using our state-of-the-art (3axis, 4axis, and 5 axis) milling machines we can manufacture the parts you need and have them to your factory floor quickly to meet your production demands. We manufacture precise and burr free parts out of just about any material required. Give us a call or e-maill request a quote and see what we can do for you. Check our CNC milling metal parts hrer.

Increased Responsiveness - Streamlined Processes Making Better Products and Solutions for Our Customers

Manufacturing Experience

Capabilities in fabrication, machining, and finishing enable us to offer one-stop shopping, our mechanical engineers have more than 15 years of processing and manufacturing experience.

Technical Support

Accurate dimensions and specifications based on your demands and a variety of instruments, competitive prices, and the highest standard quality provide the most economic solution. We do custom sheet metal fabrication right.

Quality Control

Tuofa precision machining shop has passed ISO9001 certification, Offers competitive CNC parts prices for low volume prototypes, and cost savings for high volume production runs. Take a look on the finest sheet metal stamping dies.

As one of the best precision machinery suppliers in China, 100 CNC machines for online custom precision machining service , making it an excellent choice for rapid prototyping and low to high volume production runs, instant CNC parts quotes, low-cost on-demand manufacturing, 30+ materials Perfect &10+ surface finishes for tolerances down to 0.005mm.

High Precision Standard For Gear Manufacturing Services

Quality control and precision inspection carried out by our in-house engineering analysis team ensure your parts meet the precise tolerances your project requires.

Our machining team is your machining team. At Tuofa we are focused on delivering a great environment for our employees to thrive. Tuofa employees are experts in the manufacturing environment and are passionate and dedicated to providing the highest level of quality and customer service. Together we form a team you can count on. Our years of experience coupled with cutting-edge equipment provide the highest end product possible. We will work with you every step of the way to ensure a fast and productive turnaround. Start to mechanical parts online from today.

Certificates Obtained by 15 Years of Gear Manufacturing Experience

|

|

|

|

Machining Shop For Gear Manufacturing Services

Tuofa factory provides comprehensive one-stop-shop metal parts solutions. From design, drawing, material selection, product cost accounting, production processing and assembly, inspection, delivery, after-sales, and other services.

Tuofa is one of the best manufacturers of CNC machining processes in mainland China. It's mainly in CNC machining parts, CNC milling parts, auto lathe parts, stamping parts, Sheet metal parts, and CNC turning parts manufacturing.

We can process materials such as steel, aluminum, copper, titanium alloys, plastics, and more than one hundred material types and dozens of surface treatments such as sandblasting, anodizing, polishing, and electroplating. We provide one-stop supporting services, from design, drawing, material selection, product cost accounting, production processing and assembly, inspection, delivery, after-sales, and other services.

See More CNC machining shop for Precision Machining CNC Parts here.

Product Capacity

Production Flow

|

|

|

|

|

| Raw Material | CNC Workshop | CNC Workshop1 | CNC Workshop2 |

|

|

|

|

| Depilation Workshop | Inspection Packaging | Guarantee Workshop | Production Storage |

Production Equipments

| Name | Quantity | Verified |

| Cnc Machine 3,5 Axis | 5 | |

| CNC Machining Center | 35 |  |

| CNC Milling Machine | 15 |  |

| CNC Lathe Machine | 15 |  |

| CNC Drilling Machine | 10 |  |

| CNC Polishing Machine | 5 |  |

| Sheet Metal Fabrication Production Lline | 3 |  |

| CNC Polishing Machine | 6 |  |

| CNC Blasting Machine | 5 |  |

Quality Assurance - Custom CNC Machining Parts to complete your order delivery

A Custom CNC Machining service manufacturer focusing on customer personalized parts for 16 years.

See More Quality Assurance for CNC Machining service.

|

|

|

|

|

|

|

Roughness Tester |

Hardness Tester |

Height Gauge |

2D Measuring |

CMM |

Tuofa Partner in Precision Machining CNC parts

See More about Our precision machining cases.

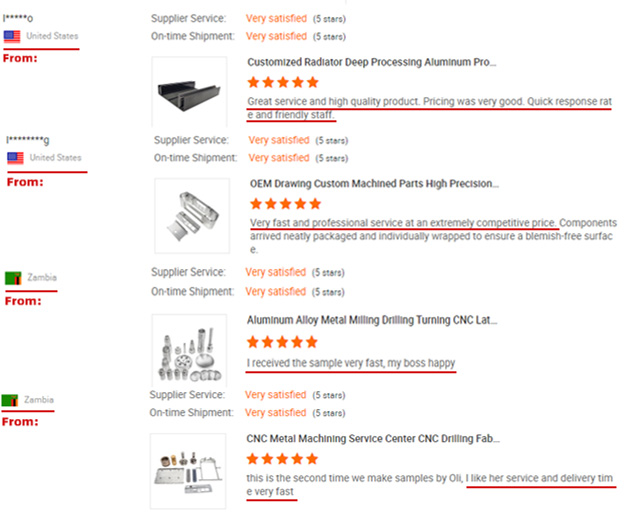

Comments on our precision machining

Comments on our precision machining

Comments on our precision machining

Comments on our precision machining

Packing & Shipping for Precision Machining CNC Parts

China's developed freight logistics is more convenient for Tuofa manufacturing to serve the world.

FAQ about Precision Machining

See more about the FAQ of precision machining.

| How can I get a quotation from your company? |

|---|

|

A: Send us an e-mail. To quote you as soon as possible, we need the following information:

|

| Q: Can I get a sample for inspection? How soon can I get samples? |

|

A: Depending on your specific project, it usually takes 5 to 10days. but a single sample will charge a fee. For batch production we will provide a free sample for check before mass production, but you are expected to pay the freight. |

| Q: How to enjoy the OEM services? |

|

A: Usually, based on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you. |

| Q: Can you make machining parts based on our samples? |

|

A: Yes, we can make measurements based on your samples to make drawings for machining parts making. |

| Q: Is it possible to know how are my products going on without visiting your company? |

|

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

| Q: I want to keep our design secret, can we sign NDA? |

|

A: Sure, we can sign NDA. |

| Q: What if I want a custom part but I can't draw? |

|

A: We can also offer a design service as long as you tell us all your requirements. |

| Q: Whether small/big orders is allowed in your company? |

|

A: Yes, welcome. |

Application Industry of Gear Manufacturing

Precision Parts can be a cost-effective alternative to casting and machining. The process is also fast and produces minimal material waste.

Precision Machining is widely used in industrial and consumer parts, as well as automotive, aerospace, energy, robotic, s and other professional industries.

Electronic Industry

Medical Industry

Automotive Industry

Agricultural industry

Machine tool industry

Aerospace industry

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home