Density of Titanium: Specific Gravity and Atomic Structure

Oct 15,2024

Oct 15,2024

Titanium has high strength, corrosion resistance and low material density. It is non-magnetic and has a silver-greyish appearance. Titanium is found in the form of oxides in the ore. And it is extracted from mineral ilmenite and rutile. It is known for its high strength-to-weight ratio. A detailed review on the importance of titanium density and strength in material science and engineering is covered in this writing.

Is Titanium Dense?

Titanium is a low-density material which is suitable for applications which require higher strength and low density.

What is the Density of the Titanium?

Density defines as mass per unit volume. It is the mass of a material occupied at one unit volume. It is relatively lower than steel (7.8g/cm3) and aluminum (2.7g/cm3).

Density of Titanium lb/in 3

Titanium bulk density is 0.163 lb/in3 at room temperature

Titanium weight per cubic feet

Titanium bulk density weight per cubic feet is 281.1lb/ft3 at room temperature.

Density of Titanium g/cm 3

Titanium bulk density is 4.50g/cm3.

Ti-6Al-4v density kg/m3

Density of Titanium Ti-6Al-4V is 4430kg/m3. Ti-6Al-4V properties are very exceptional and have high biocompatibility and Osseo conductivity.

How Does Density Affect Titanium’s strength-to-weight ratio?

Low material density of titanium is valuable in aerospace which requires high strength-to-weight ratios. because less weight does not affect performance. It is 1.8-2.5 times stronger than steel due to the Titanium atomic structure.

Density of Common titanium Alloys

The common titanium alloys are grade 2, grade 5, and grade 9, grade 12, Beta C. These are all classified based on the alloying additions. Grade 2 is all titanium.

Density of grade 5 titanium

Grade 5 is Ti-6Al-4V. It is classified as an alpha-beta alloy. The Ti-6Al-4V properties like material density is 4.43g/cm3.

Density of grade 2 titanium

Grade 2 has a material density of 4.51 g/cm3. It is 60% less dense than steel. Grade 5 is harder and has higher strength.

Why is the Density of Titanium So Low?

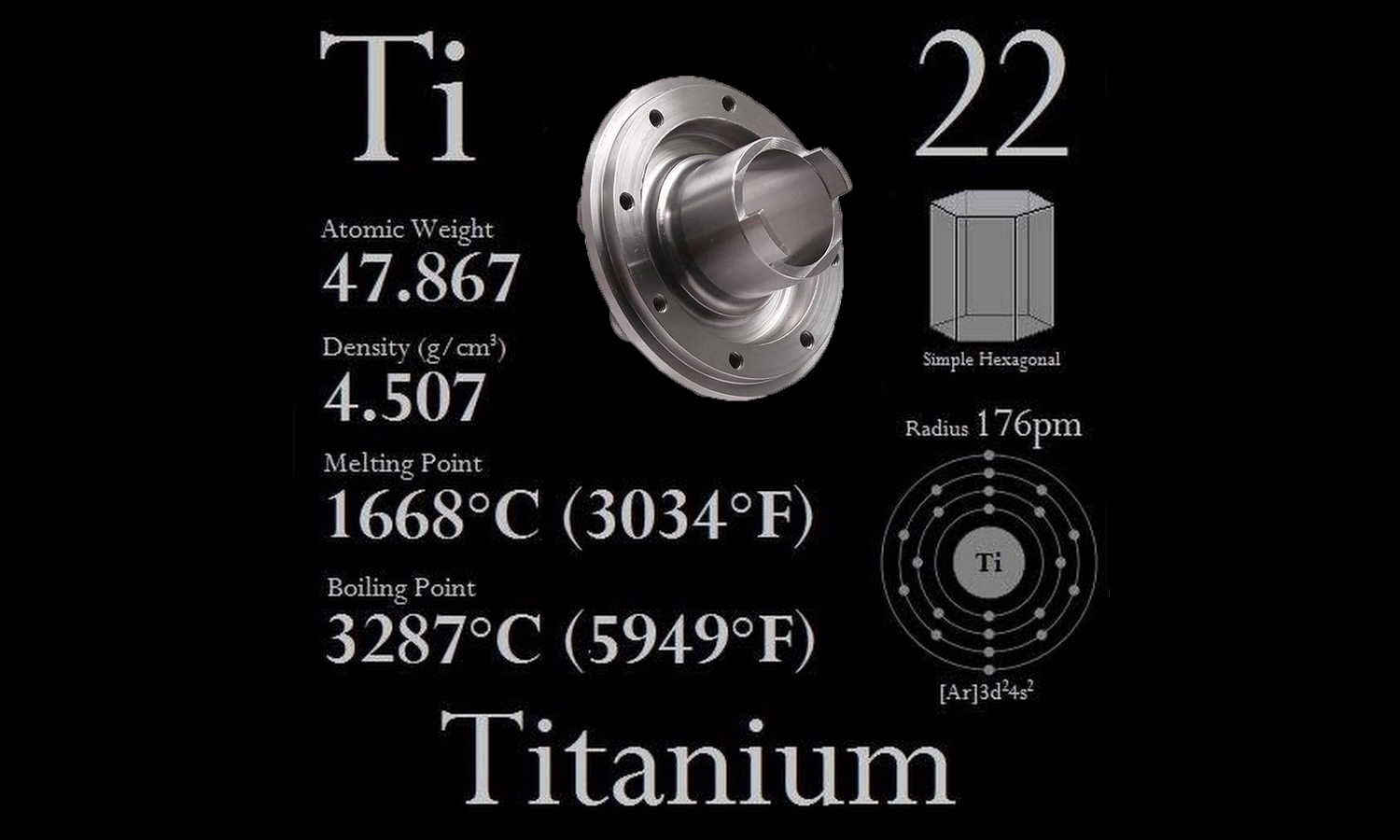

The titanium atomic structure is one of the reasons its lower density. It has HCP (Hexagonal crystal structure). Atomic weight of titanium is 47.867u. The mass, size and arrangement of atoms determine the density of a material. Less density is due to Titanium atomic structure.

Density of Titanium Alloys in Different Conditions (Annealed vs Hardened)

Grade 5 titanium is normally used in annealed and age hardened conditions. When a heat treatment is given to titanium it increases the kinetic energy of molecules which spread further apart. This makes them occupy a larger volume and decrease the material density of titanium. When titanium metal or ally is cooled does it also slows down the molecules and get closer together. This occupies smaller volume and increases the density of titanium. Other mechanisms that can affect the density if formation of vacancies.

Factors Influencing the Density of Titanium

Factors like temperature and pressure have a significant influence on density of titanium.

Temperature and Pressure Effects on Titanium Density

When the temperature is high, density decreases because of loosely held molecules. Lower temperature decreases the density. However, high pressure increases density. The interparticle spacing decreases due to molecules getting closer to each other. Volume decreases which increase density.

What is the Atomic Mass of titanium and Why Does it Matter?

The Atomic weight of titanium is 47.867u. It shows the average weight of all the naturally occurring Ti isotopes. The mass of protons, neutrons, and electrons collectively determine the atomic weight of titanium. It is important to know the average mass of elements and molecules and to solve stoichiometry problems.

How is the Density of Titanium Measured?

Density of titanium is measured with experimental methods with precise calculations. Pycnometer is one method in which the occupied mass is measured when placed in a liquid. This is measured by determining the displaced amount from an object. And then the density is determined accordingly. Another method is using Archimedes’ principle. Furthermore. X-ray diffraction (XRD) is also used to determine the atomic structure at large scales.

How the density of titanium Impacts Practical Applications

Titanium density in aerospace is considered very important. The use of titanium in aircraft parts reduces fuel consumption and improves efficiency.

The less specific gravity of titanium and high strength-to-weight ratio is valuable in high performance auto parts like wheels having improving speed and agility while maintaining durability.

Furthermore, its lower density is valuable for biomedical applications such as bio implants and surgical tools. Sports equipment is also made of titanium due to less weight.

Titanium is also used in chemical industries because of higher chemical and acidic resistance in pipelines, reactors, and heat exchangers

Comparing the Density of Titanium with Other Metals

Density of titanium vs steel

The density steel is 8g/cm3 and the specific gravity of titanium is 4.5 g/cm³. Titanium is 1.8-2.5 lighter than steel.

Density of copper vs titanium

Copper has a higher density which is 8.94 g/cm3. It is two times higher than titanium

Density of brass vs titanium

Brass is heavier than titanium has density of is 8.54 g/cm3

Density of titanium vs aluminum

Aluminum has a density of 2.7 g/cm3. It is 66% lighter than Titanium.

Why titanium’s lower density is Advantageous

Titanium is advantageous due to its high strength to weight ratio and low density. It makes it desirable for aerospace and biomedical implants.

Titanium vs. Other Lightweight Metals

Density of Titanium vs Magnesium

The density of Magnesium is very little which is 1.74g/cm3. It is 50% lighter than titanium,

Density of Titanium vs Carbon Fiber

Carbon fiber is much lighter than titanium. It has density of 1.6g/cm³ while the Specific gravity of titanium is 4.5 g/cm³,

FAQ

What Metal Has the Lowest Density?

Lithium is the lightest metal with a density of 0.534 g/cm3

What is the Densest Metal?

Osmium is the densest metal with a density of 22.59g/cm3 at room temperature

Can Titanium Float in Water?

Titanium bulk density is higher, and it is denser than water, so it does not float in water. It sinks when placed in water.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Melting Point of Aluminum: A Complete Guide

Melting Point of Aluminum: A Complete Guide