Are stainless-steel CNC parts difficult to machining?

Apr 07,2022

Apr 07,2022

CNC machining solution of stainless steel parts

Compared with parts of other materials, stainless steel precision parts will have more problems in processing, which leads to some CNC factories being unwilling to machining stainless steel precision parts. Shenzhen Tuofa metal works Inc. has rich experience in the processing of stainless-steel precision parts and has achieved excellent results in product accuracy, stability, and production efficiency. The stainless-steel parts produced in our factory are usually manufactured with conventional grades such as SS201, SS301, SS303, SS304, SS316, SS316L, SS420, etc. Because of its good formability, compatibility, corrosion resistance, and strong rigidity, stainless steel parts are universally used in automotive, electric power, aviation, medical, automation equipment, petroleum, and food industries.

The following introduces the processing difficulties and solutions for stainless-steel parts in detail.

1. Severe work hardening

Among the stainless steels, the work hardening phenomenon of austenitic and austenitic-ferritic stainless steels is the most prominent. Because of the high plasticity of stainless steel, the material is twisted during plastic deformation, and the enhancement factor is large. Austenite is not stable enough, under the action of cutting stress, part of austenite is transformed into martensite. In addition, under the action of cutting heat, compound impurities are easily decomposed and distributed in a dispersed manner, resulting in a hardened layer during cutting. The work hardening produced by the previous feed, or the previous process, seriously affects the smooth progress of the subsequent process.

2.Machining lathes with large cutting forces

The cutting force of machining stainless steel is large, and the plastic deformation of stainless steel is large during the cutting process. The work hardening of stainless steel is severe, and the high thermal strength further increases the cutting resistance. The curling and breaking of chips are difficult.

3.high cutting-temperature

During cutting, the plastic deformation and the friction between the tool are large, and the cutting heat is generated. In addition, the thermal conductivity of stainless steel is low, and a large amount of cutting heat is concentrated on the interface between the cutting area and the chip, resulting in poor heat dissipation conditions.

4.Chips are not easy to break and easy to stick

The plasticity and toughness of stainless steel are exceptionally large. The continuous chipping during turning will not only affect the smooth operation of the operation but also crush the processed surface. Under elevated temperatures and high pressure, stainless steel has a strong affinity with other metals and is prone to adhesion and the formation of built-up edges. It increases tool wear and tear, which deteriorates the machined surface. This characteristic is particularly prominent in lower carbon martensitic stainless steels.

5.Cutting tools are prone to wear

The affinity in the process of cutting stainless steel causes bonding and diffusion between the chips, thereby causing bonding wear and diffusion wear on the tool. As a result, the rake surface of the tool has a crescent crater, and the tool edge will also form tiny peelings and gaps. In addition, the hardness of carbide particles in stainless steel is high, and direct contact with the tool during cutting will rub the tool. Tool wear will be aggravated by the phenomenon of work hardening.

6.Large coefficient of linear expansion

The linear expansion coefficient of stainless steel is about 1.5 times that of carbon steel, and the workpiece is prone to thermal deformation under the action of cutting temperature, making it difficult to control the dimensional accuracy of the workpiece.

Although stainless steel precision parts have the characteristics of difficult processing, Shenzhen Tuofa Technology Co., Ltd. has 17 years of processing experience with stainless steel parts. According to numerous factors, the solutions to the problem of the difficult processing of stainless steel are as follows:

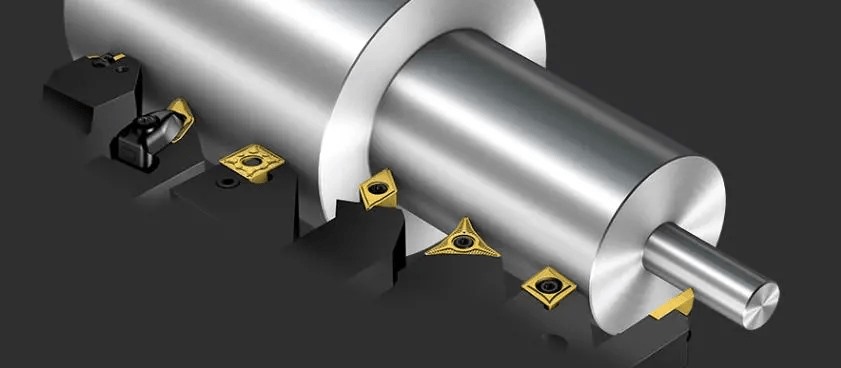

A.Selection of tool material

Due to the large cutting force and high cutting temperature when machining stainless steel parts, cubic boron nitride inserts that are second only to diamond in hardness and can withstand hot temperatures can be used. In addition, its chemical inertness is large, and it has no chemical effect with iron group metals at 1200-1300 ° C, so it is very suitable for machining stainless steel materials.

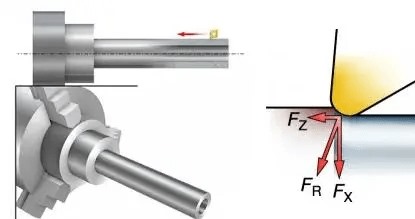

B.Tool geometry

The geometric parameters of the tool play a key role in its cutting performance. To make the cutting light and smooth, the carbide tool should adopt a larger rake angle to improve the tool life. This is beneficial for strengthening the blade and giving full play to the superiority of the high compressive strength of the ceramic tool. The tool's wear and blade strength are both affected by the relief angle's size. The change in the entering angle will affect the changes in the radial cutting force and the axial cutting force, as well as the size of the cutting width and cutting thickness.

C.The roughness value should be smaller when the rake surface is sharpened

Chip sticking to the knife can be avoided by thoroughly sharpening the tool's front and flank surfaces to ensure a low roughness value, which reduces chip flow resistance and prevents chips from clinging to the knife.

D.The tool edge of the knife should be kept sharp

The tool edge should be kept sharp to reduce work hardening, and the feed rate and the amount of back cutting should not be too small to prevent the tool from cutting into the hardened layer and affecting the service life of the tool.

E.Pay attention to the grinding of the chip breaker

Due to the strong and tough characteristics of stainless-steel chips, the grinding of the chip breaker on the rake face of the tool should be appropriate, so that the cutting process is convenient for chip breaking, chip holding, and chip removal.

F.The choice of cutting oil should be appropriate

Because stainless steel has the characteristics of easy adhesion and poor heat dissipation, it is important to choose a specialized stainless-steel cutting oil with good anti-adhesion and heat dissipation in cutting.

G.Choosing the amount of cutting

According to the characteristics of stainless-steel materials, low speed and a large feed rate should be used for cutting.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

9 Steps of CNC Turning Machining Parts

9 Steps of CNC Turning Machining Parts