Grade 301 Stainless Steel: Properties and Advantages

Oct 07,2024

Oct 07,2024

301 stainless steel is an austenitic stainless steel with Cr and Ni as main constituents. This steel grade provides corrosion resistance, great toughness, weldability and strength. It is the non-magnetic grade of steel. This article will help you understand 301 stainless steels composition, limitations and applications.

Material 301 Stainless Steel

301 stainless steel is one of the 300 series. It is an austenitic stainless steel that has an FCC crystal structure. You know that this steel provides great strength with high corrosion resistance because of Cr and Ni, it is also called Ni-Cr alloy.

For further information visit,

What does CRES Stand for in 301

CRES stands for Corrosion Resistance in 300 series of steel. Since this steel grade contains 17% Cr and 7% Ni, this grade comes in the market with great corrosion resistance.

Is 301 Stainless Steel Good?

Yes, you can say it is a good grade as you know stainless steels are known for their corrosion resistance. 301 stainless steel is one of the commonly used grades in the market.

Is 301 Stainless Steel Magnetic?

No, you wouldn’t see magnetic behavior in 301 stainless steels in annealed condition because of its austenitic microstructure. This microstructure has an FCC crystal structure.

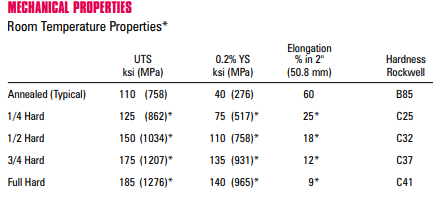

Grade 301 Full Hard Stainless-Steel Properties

In the annealed condition, hardness is 85HB. When it is ¼ hard, then the hardness is 255 HB. 1/2 hard steel shows 301 HB hardness. Full hard 301 stainless steel shows a hardness of 388 HB.

Does 301 Stainless Steel Rust?

No, this grade does not rust because of 18% Cr in its composition in normal conditions. But when the environment is chloride-rich or in marine applications, this steel rusts. Still, this grade provides decent corrosion resistance in sea environments.

Different Terms for 301 Stainless Steel

301 stainless steel may be referred to by different terms in various industries and regions. Some common alternate names include AISI 301, UNS S30100, and EN 1.4310. Regardless of the terminology used, they all refer to the same versatile stainless steel grade.

| Region | Term for 301 Stainless Steel | Standard/Nomenclature System |

|---|---|---|

| United States | 301 Stainless Steel | AISI, UNS S30100 |

| Europe | 1.4310 (X10CrNi18-8) | EN, DIN |

| Germany | 1.4310 | DIN |

| Russia | Varies (GOST-specific term) | GOST |

| Japan | SUS 301 | JIS |

| China | 0Cr18Ni9 | GB (Chinese National Standard) |

AISI 301 Heat Resistance Room Temperature-Specific Strength

At lower temperatures, this grade offers great oxidation resistance due CrO2 protective layer. But at temperatures higher than 800ᵒC, the CrO2 layer starts to break down, so oxidation resistance decreases beyond 800ᵒC. You can study further.

Is 301 Stainless Steel Heat Treatable?

This is the typical grade of stainless steel which can’t be hardened by heat treatment. Yes, you can remove stresses through stress-relief annealing but can’t increase its hardness. Only cold work is done to increase the strength and hardness.

Advantages and Disadvantages of Using 301 Stainless Steel

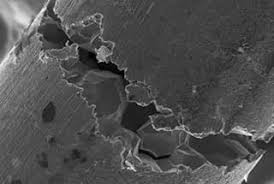

The main advantage of using 301 stainless steel is its corrosion resistance due to high Cr content i.e. 18%. But the main disadvantage is due to Cr too when improper heat treatment is done. When this grade is used at high temperatures i.e. 450ᵒC-850ᵒc, Cr comes out from the grains and makes CrC3, which makes grain boundaries weaker. This effect results in intergranular corrosion. Study further.

Study further IGC,

The first figure shows breakage in a grain boundary, while the second figure shows IGC in an application.

Try Tuofa Now!

Send drawings to info@tuofa-cncmachining.com

China Tuofa Engineer Support Team

Real human quotes are more accurate than software quotes

What is 301 Stainless Steel Used For?

Since this grade is malleable and ductile, its machining is easier, that’s why it is used to make decorative parts in architecture. It is used for trim and wheel covers in the automobile industry. In the kitchen, it is used for utensils and tableware. Due to its biocompatibility, it is used in the production of implants and medical devices.

You can study, further its applications https://www.youtube.com/watch?v=BvWJogBWBfU&pp=ygUlV2hhdCBpcyAzMDEgU3RhaW5sZXNzIFN0ZWVsIFVzZWQgRm9yPw%3D%3D

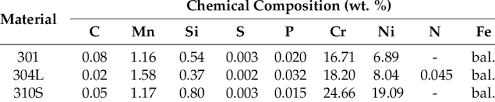

SS301 Chemical Composition Chart

Cr Increases corrosion resistance, Ni increases strength, Mn Increases mechanical properties, Si Increases oxidation resistance, and P Improves machinability.

Physical Properties of SS 301

Physical properties include density, thermal conductivity, electrical conductivity and thermal expansion. These properties are briefly discussed below:

Density

The density of SS301 is 7.93 g/cm3, which is why it is used in aerospace because it is more lightweight than high-strength steel.

Electrical Conductivity

The electrical Conductivity of SS 301 is 1 X 10^6 S/m. Its resistivity is higher compared to conductive metals.

Thermal conductivity

The thermal conductivity of SS 301 is 16.3 W/mK.

Thermal Expansion

The thermal expansion of SS 301 is 17.3 µm/mK. This value of expansion is considered moderate expansion.

SS 301 Mechanical Properties

Mechanical properties of any material are important in terms of their suitability for applications. The main properties include hardness, yield strength, tensile strength and breakage resistance.

SS 301 Hardness

As you know, we have discussed the hardness of SS 301 in one of the above headings. After different heat treatment procedures, SS 301 shows different hardness. In general, the hardness is 85 HB.

301 Stainless Steel Hardness HRC

On the Rockwell scale, SS 301 steel shows an HRC hardness of 5.6 HRC.

HB

On the Brinell hardness scale, SS 301 shows a hardness of 85 HB.

HV

On the Vicker Hardness scale, the hardness is 90-100 HV.

Yield Strength

Yield strength of SS 301 is 205 MPa.

Tensile Strength

In an annealed condition, the tensile strength is 515 MPa.

Chinese Machining Services

Send drawings to info@tuofa-cncmachining.com

Faster and Cheaper

Machining and Welding of 301 Stainless Steel Parts

The composition of SS 301 contains 7% Ni. Ni stabilizes the austenitic phase of steel and contributes to toughness and ductility. The austenitic phase is relatively softer than the ferritic and martensitic phases. Due austenitic phase, SS 301 provides excellent machinability and weldability.

FAQ

301 Stainless Steel vs 304

301 stainless steel has a Cr content of 17% while 304 stainless steel contains 18-20% Cr. 304 has lower hardness than 301 grade. 301 stainless steel is used in springs, automotive parts and structural components while 304 stainless steel is used in kitchen equipment, chemical containers and marine applications.

Is 301 Stainless Steel Better than 316?

Both grades are almost the same in terms of corrosion resistance, machinability and weldability. But 301 is used where the primary importance is strength like aircraft parts while 316 is used where the primary importance is corrosion resistance like in marine applications. So, both are better according to their applications.

201 vs 301 Stainless Steel

The main difference is of C content. 201 stainless steel contains a lower content of C. That lower content causes a decrease in strength and hardness. 301 provides higher rust resistance than 201grade.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Grade 201 Stainless Steel: Properties and Advantages

Grade 201 Stainless Steel: Properties and Advantages