What Is Spring Steel? -A Guide of Grades, Machining & Design

Nov 26,2025

Nov 26,2025

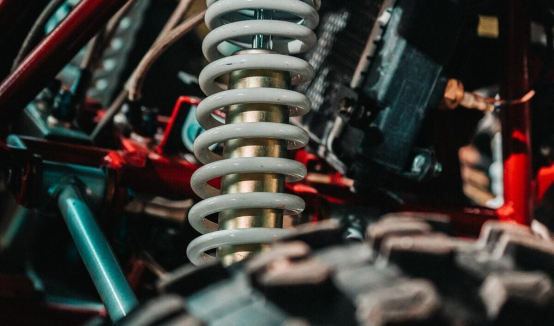

A lot of mechanical systems around us are obliged to absorb shocks and unintended energy. As an example, the suspension system of a car must absorb the shock from a pothole on a road during driving. Otherwise, the passengers will experience an unwanted riding experience. Spring steel provides just that! It has the capability to absorb a high amount of energy without permanent deformation. That's only a little example. There are numerous applications of this incredible material.

What Is Spring Steel?

Spring steel is special type of steel that has ability to retain its shape without permanent deformation even under a high load. Spring steel has a high yield strength and high elasticity. These properties make spring steel especially suitable for applications that require shock absorption.

Spring Steel Definition

- How Did Smiths Make Spring Steel?

Traditionally, black smiths developed techniques through trail and error to produce spring steel. They made high-carbon steel to go through a heating, quenching and tempering sequence. In that way, a durable and tough steel was produced for high end application of that era.

How Spring Steel Differs from Plain Carbon Steel

Let's check out: “what's the difference between spring steel and regular steel?”. In comparison to carbon steel, spring steel has a high yield strength, high elasticity, good toughness and fatigue resistance. The chemical composition and heat treatment is a bit different. As a result, spring steels develop an ability to flex deeply and return to its shape.

Is Spring Steel Hard or Soft?

Spring steel is harder than plain carbon steel. The high carbon content together with alloying additions like Si, Mn, V, Cr etc make it harder. The heat treatment enhances the hardness further.

Spring Steel vs Stainless Steel

While spring steel is mainly used to its high elasticity, stainless steel is used primarily for its corrosion resistance. For applications requiring high-strength, spring steel is always the ideal choice for machining material.

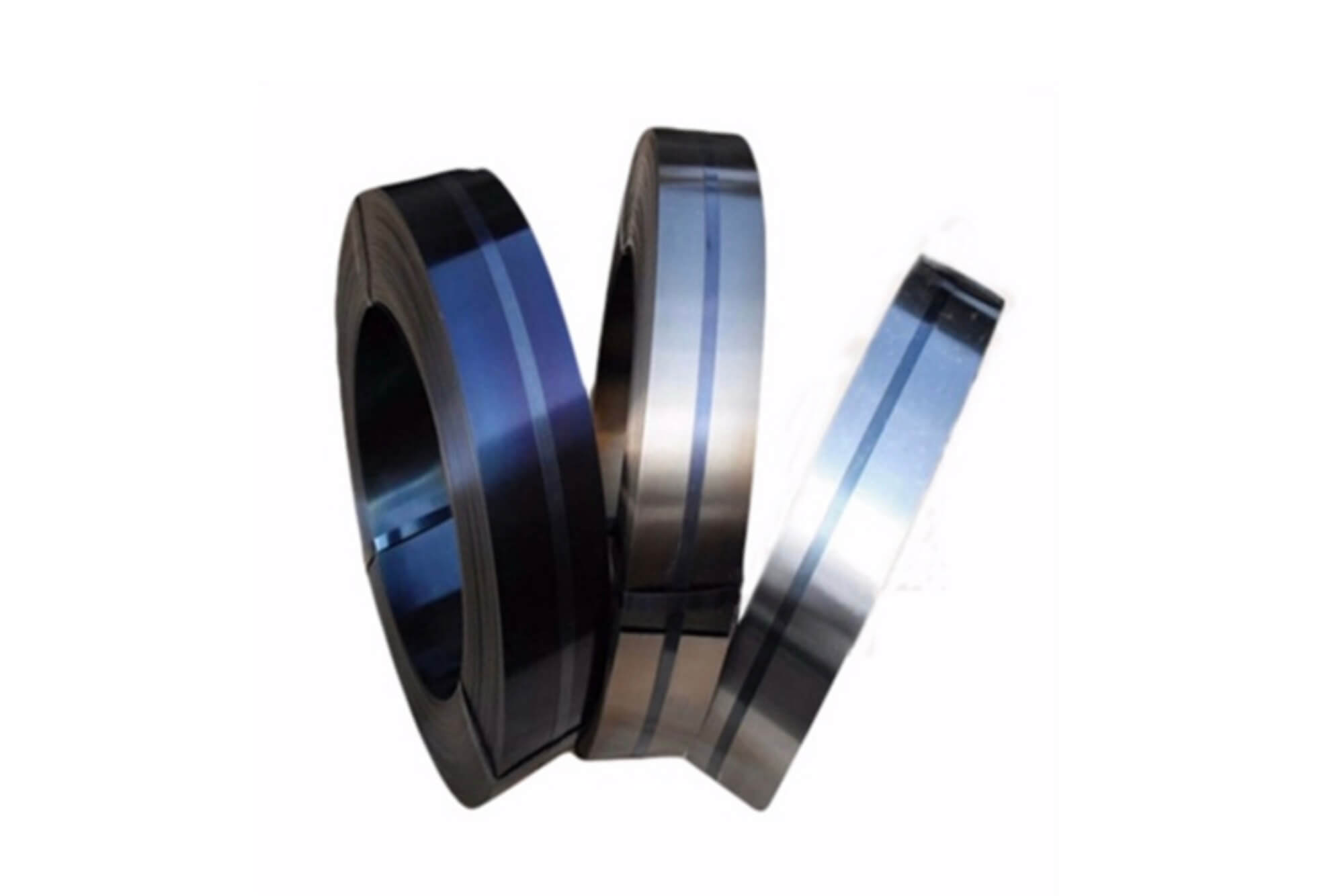

Key Grades of Spring Steel

Most of the time, spring steel is called that because it is frequently used to make springs; functionally, the following metals are classified as such because of their superior spring properties. For example, 17-7PH stainless steel, which is classified as a semi-austenitic precipitation-hardening stainless steel from a materials science perspective, is also commonly referred to as "spring steel" after heat treatment. So, broadly, spring steel can be classified into 4 categories:

1. Carbon Spring Steels: 1075, 1095, 5160

Plain carbon spring steels are the lowest in cost. Carbon steel gives their high yield strength and high elasticity due to a high carbon content. Normally, carbon content ranges from 0.6- 1.0%.

Which Is Better, 5160 or 1095 Steel?

5160 grade spring steel have a higher toughness level than 1095 grade spring steel. It is because the strength of 5160 grade spring steel relies on carbon and a small addition of Cr. On the other hand, in 1095 grade spring steel the strength relies entirely on the high carbon content which makes very hard and brittle phases.

|

Feature |

5160 |

1095 |

|

Composition |

0.6% C (medium carbon) + 0.8% Cr |

0.95% C (high carbon) |

|

Mechanical Behavior |

Tough, flexible, excellent shock resistance |

Very hard, high wear resistance but less tough |

|

Machinability |

Easier to machine; chromium improves hardenability |

Harder to machine due to high carbon |

|

Heat Treatment |

Wide heat-treat window; forgiving |

Narrow heat-treat window. It can become brittle if over-hardened |

|

Applications |

Large knives, swords, leaf springs, impact tools |

Small blades, razors, springs requiring high hardness |

|

Reason |

Resists cracking during rough use |

Forms very hard martensite and holds a sharp edge |

- 5160 and 50CrV4

Grade 5160 spring steel and 50CrV4 spring steel are very similar in composition and mechanical properties. The only difference is that of the micro alloying with vanadium in 50CrV4 spring steel. The addition of V refines the grain structure that results in enhancement in strength and toughness.

2. Alloy Spring Steels: 60Si2Mn, 55CrSi

Alloying additions like Si, Cr and Mn increase the strength and toughness tremendously. Silicon is one of the most important alloying elements in spring steel. It modifies the microstructure in a way that yield strength that yield strength and elasticity improves tremendously. Mn and Cr improve hardenability and strength. 60Si2Mn and 55CrSi are common alloy spring steel grades.

3. Stainless Spring Steels: 301, 302, 17-7PH

Stainless spring steel is more costly than other spring steel grades. All stainless spring steel have a high Chromium content which creates a corrosion protective layer over the surface. 301 grade has a slightly higher carbon content and a lower Nickel content than 302 grade. Comparatively, 301 grade is a bit stronger than 302 grade. On the other hand, 302 grade is more corrosion resistive.

|

Aspect |

301 grade spring steel |

302 grade spring steel |

|

Carbon |

Higher |

Lower |

|

Nickel |

Lower |

Higher |

|

Strength After Cold Work |

Higher |

Moderate |

|

Martensite Formation |

More |

Less |

|

Corrosion Resistance |

Good |

Better |

|

Formability |

Very good |

Excellent |

|

Best For |

High-strength springs |

Corrosion-critical springs |

17-7 PH stainless steel is another material that is used in springs. 17 and 7 denote the percentages of Cr and Ni. “PH” indicates that it is a precipitation hardening alloy. It means that its is formed in a softer state while strength increases during ageing.

4. Music Wire (ASTM A228)

Music wire is made up of a very good quality material. As these wires are cold drawn, their elasticity is improved during to cold working. Normally, they can be made up of high carbon steel. Alloying additions enhance the spring behavior characteristics.

Composition and Mechanical Properties

Chemical composition of spring steel plays an important role in the modification of micro-structure. This modification leads to changes in mechanical properties. Each alloying element has its own specific function in the improvement of responses to cyclic loading, bending, torsion, and impact.

Roles of C, Si, Cr, and V

Carbon and silicon are the most important alloying elements in spring steels. Carbon strengthens steel though interstitial hardening and carbide formation. Silicon helps in microstructural refinement. It suppresses cementite formation and favors the formation of martensite. Chromium forms hard carbides. Vanadium is a microalloying element. Even a small percentage of V refines the microstructure greatly.

Mechanical Properties of Spring Steel

1075 Mechanical Properties

|

Property |

Nominal Value |

|

Tensile Strength |

900 - 1200 MPa |

|

Yield Strength |

650 -950 MPa |

|

Elastic Modulus (E) |

200 GPa |

|

Shear Modulus (G) |

80 GPa |

1095 Mechanical Properties

|

Property |

Nominal Value |

|

Tensile Strength |

1200- 1600 MPa |

|

Yield Strength |

950 -1300 MPa |

|

Elastic Modulus (E) |

200 GPa |

|

Shear Modulus (G) |

80 GPa |

5160 Mechanical Properties

|

Property |

Nominal Value |

|

Tensile Strength |

900 - 1300 MPa |

|

Yield Strength |

700 -1100 MPa |

|

Elastic Modulus (E) |

200 GPa |

|

Shear Modulus (G) |

80 GPa |

60Si2Mn Mechanical Properties

|

Property |

Nominal Value |

|

Tensile Strength |

1300 -1500 MPa |

|

Yield Strength |

1100 -1300 MPa |

|

Elastic Modulus (E) |

205-210 GPa |

|

Shear Modulus (G) |

80 GPa |

17-7PH Mechanical Properties

|

Property |

Nominal Value |

|

Tensile Strength |

1500 -1750 MPa |

|

Yield Strength |

1200 - 1500 MPa |

|

Elastic Modulus (E) |

200 - 205 GPa |

|

Shear Modulus (G) |

77 -80 GPa |

Heat Treatment Before Machining

Heat treatment is a necessary step for the adjustment of hardness, machinability and elasticity in spring steel. A lower hardness is desired for machining and a high elasticity is required afterwards. Normally, spring steel is annealed before machining and quenched and tempered afterwards.

How to Heat Treat Spring Steel?

- Annealing: Austenitize at 760OC and then furnace cool till 550-600O Then air cool.

- Hardening: Austenitize above 800OC and then hold for some time as per the section thickness. Then quench in oil.

- Tempering: Heat till 300-500OC and hold it for some time. Then cool slowly.

Why Heat Treatment Is Necessary for Spring Steel

As rolled or annealed spring steels do not possess a high level of elasticity. In order to impart the desired properties, they go through a quench and temper sequence.

CNC Machining Spring Steel and Machinability

CNC machining of spring steels allows for complex parts to made with a high precision. But, an experienced machining setup and proper settings are required for achieving good results.

- Is Spring Steel Machinable?

Spring steel is a difficult tot machine material. It has a high hardness that prosses problems in cutting. With the use of proper settings and heat treatment high quality parts can be made from spring steel.

Machine in Annealed State vs After Heat Treat

Machining in annealed state is always easy. The hardness value comes to lower number that makes cutting easy. On the other hand, after heat quenching and/ or tempering the surface of spring steel become very hard for machining.

CNC Machining Spring Steel Process

CNC Turning Spring Steel

In CNC turning, the workpiece rotates while the tool is stationary. It is commonly used for axis symmetrical shapes.

CNC Milling Spring Steel

In CNC milling, the tool moves but the workpiece remains stationary. It is used for large objects with many features. As a tip, climb milling strategy works best for spring steels.

5-Axis Machining Spring Steel

5 axis machining allows very complex features to be carved out of blanks. The tool has the flexibility to move across various orientations. The workpiece needs to be fixed once. The CNC machine will take care of all rotations.

Grinding Spring Steel

Grinding operation is carried out finishing of spring steel parts. Grinding reduce the surface roughness and fine tunes the dimensions.

Custom Machining Spring Steel Parts

Although any part can be made our of spring steel, some commonly produced parts are listed below:

- Leaf springs

- Coil spring seats

- Clamps and clips

- High-strength shafts

- Wear-resistant pins

- Knife blanks and tools

- Suspension parts

- Custom spring mechanisms

Benefits of Choosing CNC Machining Spring Steel

CNC machining weighs more than other machining processes. Even with tough grades like SAE 1095, 17-7 PH, 5160 etc, CNC machining provides promising results. Parts like clips, tools, custom springs, flat parts, or high-strength mechanical elements can be made with ease.

Tight Tolerances and Repeatability

As CNC does not depend greatly on manual settings it eliminates human error. CNC follows the CAD and CAM and hence it makes the same dimensions every time. CNC machining is ideal for spring steel parts requiring exact deflection or fit. Examples include spring retainers, shims, flat springs, locking mechanisms, and wear-resistant blades.

High Quality Finish Capability

Since settings in CNC are fixed for every duplicate part, it shows machining defects very rarely. The tolerances for finishing operations like grinding and polishing are fixed each time. So, it produces an excellent surface finish consistently.

Freedom of Design

CNC machining offers a broad flexibility in shaping. It compliments to space constraints for spring parts. Features like pockets, slots, tapers, and thin sections can be made with ease. Any revisions in designs can be easily incorporated in CAD and CAM files. So, there is no need of manual adjustments every time.

Tips to Design Your Parts

A good design is the foundation stone of high quality manufacturing. Expert designers consider every aspect of designing. Proper material selection, defining allowances and inclusion of necessary features is important in a robust design.

Choose a Proper Steel Grade

Spring steel comes in a comes different grades and classes. Each spring steel grade has its own usefulness. As an example, high carbon grades like 1095 suit best for applications that require high hardness and low cost. While, alloy grades like 5160 prioritize toughness and stainless steel grades offer corrosion resistance. It is always best to consults expert manufacturers like TUOFA for advice.

Allowance for Springback

Spring steel shows spring back effect in bending operations. So bending angles should include allowances for springback.

Functions and Features

Spring steel components should include features that minimize stress concentration. In that sense features like fillets of radii, avoidance of sharp corners and stress relief grooves are instrumental.

Applications of Spring Steel

Spring steel is widely used in applications like suspension systems, clutches, valve springs, retaining clips, and various damping components. These applications capitalize on the high elasticity and high yield strength properties of spring steel.

Automotive Parts

- Suspension Systems

- Clutches

- Valve Springs

- Retaining Clips

Industrial Machinery and Robotics

- Coil Springs

- Flat Springs

- Lock Washers

- Guiding Strips

- Robotic Mechanisms

Medical Devices and Instruments

- Surgical Tools

- Orthodontic Devices

- Precision Clamps

- Mechanical Assemblies

Custom Solutions

Spring steel is utilized in applications which require high elasticity and strength. Many manufacturers prefer spring steel for custom made parts due to high durability.

Is Spring Steel Good for Making Knives?

Spiring steel is very relevant in knives manufacturing due to its excellent toughness, edge retention, and high hardness. High carbon and silicon content allows to hardness enhancement during heat treatment. However, corrosion protection remains a problem for non- stainless steel classes.

What Is The Very Best Steel for Knives?

There is no single grade that can be considered as best. However, CPM S90V/S110V is one of the best in terms of hardness and edge retention.

Conclusion

Spring steel is a very versatile material used in many applications. Spring steels maintain their shape even after flexing too much. They have high elasticity, high strength, high toughness and high fatigue resistance. Normally spring steel are abundantly used in suspension systems and mechanical assemblies due shock absorbing ability.

FAQs

Is D2 or 1095 better?

D2 offers better wear resistance for machinery parts while 1095 is better for hardness and toughness.

Does spring steel rust?

Generally, many types of spring steels can rust. But stainless steel grades like 301 or 302 offer a good corrosion protection.

Is spring steel good for tools?

Yes. Tools made out of spring steels offer a very good dimensionally stability and wear resistance.

Is 5160 spring steel good for knives?

5160 spring steel is very good for knives. Corrosion protection still remains a problem.

Is spring steel stronger than stainless steel?

Spring steel is stronger than many steel types. Spring steel can be a sub class of stainless steel. So stainless steel grades like 17-7PH are also very strong.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Titanium Car Parts Guide: Grades, Manufacturing & Design

Titanium Car Parts Guide: Grades, Manufacturing & Design