How to Make Sheet Metal Brackets: Design & Fabrication Guide

Oct 30,2025

Oct 30,2025

Bracket is a middle part between two items to fix one with another. Bracket provides support to connect two parts. There are various metal bracket shapes and sizes depending on the requirements. One of the economical and convenient ways to make brackets is sheet metal fabrication. You need to know some basic about sheet metal brackets before finding a service provider for sheet metal prototyping or other related services. This article will guide you about the designs, types, tips and materials for sheet metal brackets.

What Are Sheet Metal Brackets?

Sheet metal brackets are objects made from a flat piece of sheet metal. These are cut, bent, and formed to provide structural support, connecting parts, and placing objects at one place. They provide a stable mounting point for large structures.

How Do Brackets Work?

Brackets connect physically two separate parts like shelf and wall and support structure by providing additional strength. They distribute loads and stress from the object to the mounting surface. Brackets can align parts and create a fixed point for large assemblies.

Pros and Cons

Brackets have many advantages like

- Sheet metal brackets are cost-effective for larger structures

- They have high strength and can withstand significant load

- These are customizable and have various metal bracket shapes like L, U, or Z shapes.

- Sheet metal brackets are lightweight

However, there are few limitations for sheet metal brackets

- Some versatile and complex can be difficult to make

- These are prone to rust and corrosion

- They need other hardware like screws or rivets, to be installed.

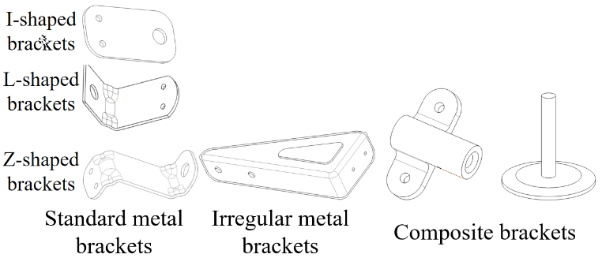

Types of Metal Brackets

The various sheet metal bracket types have their own function and purpose like some connects perpendicular surface or some wraps around the object to hold it in place. A brief description of the sheet metal bracket types is as follows:

Common Metal Bracket Types by Shape

Common types of metal brackets based on their shape are discussed below:

1. L Brackets

The L-shaped bracket is used to join two perpendicular surfaces. It is common for supporting shelves and reinforcing corners.

2. U Brackets

The U-shaped bracket is wrapped around the object. It is often used for securing pipes or cables.

3. Z Brackets

This bracket has bends in the shape of a "Z". It is used for connecting different components or offsetting them and is common in installing building facades.

4. T Brackets

The T-shaped bracket connects three surfaces. They provide a sturdy foundation for a structure.

5. Flat Bracket / Strap

A plain flat bracket is used for connecting two components in a straight line or providing reinforcement. While a curved bracket is specifically designed to wrap around or conform to a rounded object.

6. Corner Brace / Gusset Bracket

A corner bracket reinforces a corner or joint and provides extra stability. It is available in different shapes like triangular, rectangular, or trapezoidal, to distribute force and load

1. Choose the Material of Metal Brackets

Here now we are going to talk about how to make sheet metal brackets. Selection of material of metal bracket is one of the key elements in overall design process. Material decides the performance and efficiency of brackets.

Design Purposes

One of the important features to be kept in mind in designing is the lightweight bracket. For example, aluminum is strong and lightweight material and can be the best choice for sheet metal brackets.

Common Types of Metal Bracket Materials

The common types of material used in making metal brackets are:

1. Steel for Brackets

Normally cold-rolled steel is used in metal brackets. It is strong, durable and excellent for holding heavy loads like shelving or construction beams. However, it is a heavier material

2. Stainless for Steel Brackets

Stainless steel like 304 or 316 have high corrosion resistance and good physical properties. Stainless steel brackets are ideal for high-humidity environments like outdoor structures or in medical/orthodontic applications. But they are heavier than aluminum

3. Galvanized Steel

Hot-dip galvanized steel offers high corrosion resistance at a lower cost than stainless steel. But its protective coating can be damaged by welding which is visible as a crystallization pattern

4. Aluminum for Brackets

Aluminum alloys like 6061 and 5052 have excellent strength-to-weight ratio and are perfect for lightweight applications. However, they have less strength than steel.

5. Brass for Brackets

Brass like C260 and C230 are used when aesthetic finish is desired. But these are less common and not used like steel or aluminum alloys

6.Copper for Brackets

Copper is used for conductivity and decoration purposes. But it is not strong or lightweight as aluminum for structural applications

2. Design Rules for Metal Brackets

Design rules for brackets depend on the shape, material, and use of brackets. They all have different functions and specifications.

For Different Shapes

Different metal brackets shapes like L-shaped brackets are made at 90∘ -120∘ angle to connect perpendicular surfaces. U-shaped brackets offer a secure grip than L-brackets for pipes, cables, or beams. T-shaped brackets have similar purposes to U-brackets. Z-shaped brackets are used for reinforcement of heavy equipment.

For Threaded or Tapped Holes

Threaded depth in soft metals like aluminum is at least two screw diameters. In harder materials like steel, it is one screw diameter. Tapped holes are placed with smaller tolerances for critical dimensions like edge-to-hole distances.

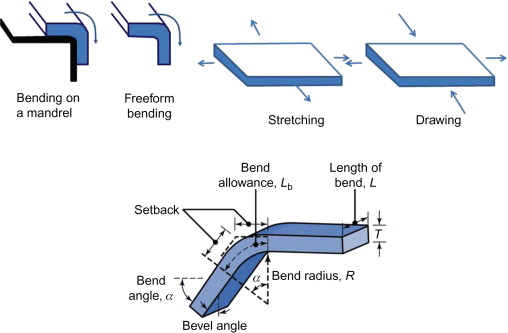

For Bending Angles

Hard metals and thicker gauges are hard to bend and cannot have extreme angles. But ductile materials have large bend radius to reduce stress concentration. Stainless steel and aluminum require larger radii to reduce springback effects.

For Industrial Uses

Brackets provide structural support and are used to attach components securely. The Desing for Manufacturability (DFM) minimizes special features like extra-high flanges or welds to reduce costs. Although welding improves strength but adds cost.

3. Create the CAD and Flat Pattern

There are few steps to make brackets patters. To create a DXF file of a sheet metal part's pattern, start with making 3D CAD model and make flat pattern in CAD software. Then export this pattern to a DXF file.

Bend Data Setup

Make a 3D model in CAD software with all the features like bends and folds. Defining bends, specify parameters like bend radius, bend angle, and material thickness.

Set Reliefs and Corners

Add reliefs like notch or slot to prevent tearing during the bend. Set up corner reliefs to prevent material bunching up at the corners.

Making Manufacturing Drawings

Create a 2D drawing from the flat pattern and export as DXF with all the manufacturing information.

4. How to Cut the Blank? -CNC, Laser, Waterjet, or Punch?

There are few ways to cut the blank. But the selection of process is based on material, thickness, precision, and speed needed.

CNC Cutting

It is a rotating cutting tool controlled by a computer (CNC). CNC is best for rigid and semi-rigid materials, like composites, plastics, and wood, and when an excellent surface finish is required.

Laser Cutting

It uses a high-powered laser beam to melt, burn or vaporize the material. a focused laser beam to cut or engrave. It is best for thin-to-medium sheet metal, plastics, wood, and acrylic.

Waterjet Method

this method uses a highly pressurized stream of water mixed with an abrasive material like garnet to erode the material. It is best for a wide variety of materials like metals, stone, glass, and plastics.

Punching

This is a mechanical process and a punch press with a punch and die set shears a shape or hole out of sheet metal. It is best for high-volume production of simpler parts or for softer metals.

5. How to Bend and Form on a Press Brake

There are few things to consider in bending and forming on a press brake. First the right tool selection and method, bending sequences and the control springback for precise final results.

Choose Tooling and Method

Understanding the required angles, radii, and tolerances for custom metal bracket. Air bending is common and requires less tonnage. Choose tools that match the desired bend angle and radius.

Plan the Bending Sequence

Plan the order which flange to bend first to avoid the punch, die, or part from hitting the machine frame.

Control Springback and Angles

Materials have different springback properties. Coining or bottoming bending significantly reduces springback.

6. How to Tap or Thread Your Brackets?

The tapping or threading process for brackets is:

- Insert the tap into the handle and make it vertical to avoid cross-threading

- Rotate the handle clockwise with consistent pressure to let the tap cut the threads on its own

- Turn the tap back to half-turn after every full rotation. This will clear the chips.

- Continue until the tap has gone through the bracket.

- Remove the tool when finished tapping in reverse direction from the threaded hole.

Conclusion

Designing and fabrication of sheet metal brackets includes the selection of material; using CAD and follow sheet metal fabrication guidelines for processes like cutting, bending, and finishing. Material strength, fatigue resistance, and environmental factors are the common factors for designing and for fabrication, choosing precision processes like CNC, laser cutting, or bending, often using custom tooling for custom metal brackets.

You do not need to be confused with how to plan the designing and fabrication for sheet metal bracket. TUOFA CNC machining service have years of experience in sheet metal bracket manufacturing services. Contact us today to get answers to all your confusion from our experts!

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Spring Sheet Metal: CNC Machining & Applications

Spring Sheet Metal: CNC Machining & Applications