Best Complex Machining Services from Tuofa China

Nov 20,2024

Nov 20,2024

CNC machining is a complex manufacturing technique in which a computer-controlled cutting tool is used for material removal. TUOFA is one of the best CNC machining services in mainland China. Tuofa has advanced CNC machines which specializes in manufacturing CNC turned, machined, milled parts, automotive lathe parts, stamping and sheet metal parts.

What is Complex CNC Machining?

Complex CNC machining is a manufacturing process which creates delicate, precise components with complex geometries. Complex manufacturing is a multi-step process to acquire desired shape and accuracy. CNC machines have high dimensional accuracy and precision. These are more efficient than conventional machining processes.

Key Characteristics of Complex Machining Processes

The complex machining process involves using multiple axes of movement, special tools, and advanced programming methods. A range of parts with a high level of accuracy can be created in complex machines that do simple tasks. Different CNC machines are used like CNC lathes, 3-axis or 5-axis machines to make components. Parts with different geometry, dimension, complexity, tolerances, end-use, and material can be CNC machined easily.

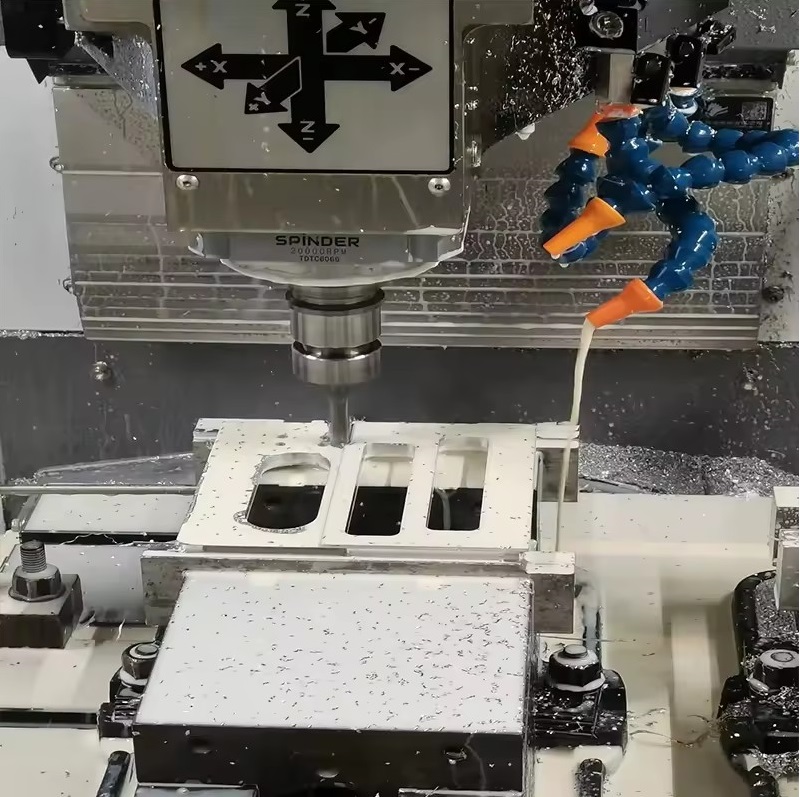

Complex Machines Images

In complex or tight tolerance precision CNC machining, computer-aided software is used to perform tasks like milling, turning or grinding.

Types of Complex CNC Machining

Complex CNC machining has some types depending on the type of CNC machines.

Multi-Axis CNC Machining (3-Axis, 4-Axis, 5-Axis)

The CNC machining process has primary difference is the movement axes which can be 3, 4, and 5-axis CNC machining. The axes degree is the moving direction of the cutting tool. Thus, the highest degree of cutting tool movement is in the 5-axis CNC machining.

CNC Turning and Milling for Complex Geometries

CNC turning are best suited for simple and cylindrical shapes. Milling is best for complex geometries. CNC milling has a rotating cutting tool and remove material from static workpiece. CNC turning has static cutting tool and workpiece is rotating.

Electrical Discharge Machining (EDM) for Intricate Parts

EDM is an advanced manufacturing method that uses thermal energy rather than mechanical force for material removal. This is the best choice for shaping and molding intricate and complex parts in hard and conductive materials. An electrode and workpiece are separated by dielectric fluid that breaks down to generate sparks. This spark erodes the material out of the workpiece.

The Role of Design Engineers in CNC Machining Services

Collaboration Between Engineers and Machinists

Engineers conduct quality control inspection in complex or tight tolerance precision CNC machining. This is one of the important steps in overall manufacturing. It involves different analysis like stress-strain analysis, microstructural analysis etc and a detailed inspection with precise tolerance specifications.

Design for Manufacturability (DFM) Considerations

DFM is a set of considerations that optimizes CNC machining process. It speeds up the process with more efficiency and cost-effectiveness, the considerations are like material selection, tight tolerance, machining strategy, pocket depth, visibility, reachability, and accessibility of machine tool

Prototyping and Design Optimization for Complex Parts

Design optimization simplifies the design by keeping a minimum number of parts, less complex features, and minimum unnecessary intricacies. Prototyping is essential to confirm the optimization capabilities. It ensures better material utilization and process efficiencies

Advanced Materials for Complex CNC Machining

Metals Used in Precision Machining

Metals in precision machining are mostly steel, aluminium, titanium, copper, carbon steel etc. Stainless steel is the most versatile alloy with several options for every application. Titanium offers best results in precision turning due to high strength-to-weight ratio. Aluminium alloys are cost-effective, lightweight and corrosion resistant materials. They have easy machinability for complex parts.

Plastics and Composites for CNC Machining

The key considerations when choosing plastics and composites for CNC machining are material's properties, applications and the processing techniques. Plastics that work best in CNC machines are acrylics, high-density polyethylene (HDPE), polycarbonate, polypropylene (PP), Teflon (PTFE), and Nylon. In composites, the matrix material is important depending on its applications. Different matrices are, Metal matrix, polymer matrix and ceramic matrix for CNC machines.

Advantages of Precision Machining for Complex Parts

The benefits of complex or tight tolerance precision CNC machining are:

- Repeatability: CNC machining offers the option of producing identical part with same level of accuracy. This feature is difficult to achieve in other machining processes.

- High Precision: complex geometries are produced with high accuracy and tight tolerance.

- Versatility: Precision machining can accommodate a variety of materials like metal, plastic, and composites.

- Cost-Effectiveness: process is overall cost effective with high precision, accuracy, repeatability and a range of material selection. This process has minimal material wastage and high-volume productions.

- Great Surface Finishing: precision machining offers surface finish with high functionality and aesthetically appealing

Challenges in Complex CNC Machining

The challenges in complex CNC Machining are

- Programming error: it can occur at any stage of processing and can create non-optimized part or unusable parts.

- Wide material selection: it can be challenging when a high range of material selection for every project.

- Vibration: it is common in machining process and can occur while drilling, milling or turning that can disturb parts geometry.

CNC Complex Machining Parts

CNC machining can create complex geometries for industries like aerospace, defense automotive, medical and submarine parts. The components are created in different level of intricacy and are usually CNC milled or CNC turned. Selection of machines depends on the geometry, tolerance, type and size of material. The accuracy of part is confirmed by CMM inspection which identifies any deviations from the design before shipment.

CNC Machining Tolerances and Surface Finish

Tolerances and surface finish are important parameters in CNC machining

- Tolerances

It determines the maximum and minimum size of part. A standard tolerance is normally ±0.005 in. for any complex mfg. But tolerance can change depending on the type of processes like lathe, milling, router, drilling or many more.

- Surface finish

It defines the smoothness or roughness or smoothness on the surface of component. Ra (average roughness) is measured in which the lower value defines the smoother surfaces. It is important to have appropriate surface roughness for CNC machined part because it has impact on friction and wear resistance of part.

Post-Processing in Complex CNC Machining

- Heat Treatment and Surface Coating Options

Heat treatments surface finish like coating, painting is applied after the machining process. It improves the surface roughness, wear resistance, friction and visual properties of CNC machined components.

- Deburring and Polishing for Complex Parts

Post-processing also includes methods like deburring, polishing, anodizing, electroplating, and sanding. These methods improve the surface finish and aesthetics of parts, it also provides additional functionalities in complex manufacturing.

- Inspection and Quality Control after Machining

The final inspection of machined parts is carried out to check the quality after complex mfg. It measures the dimensions, accuracy in size and other important critical aspects. Normally a micrometer caliper or a coordinate measurement machine is used for precision. Errors are identified and corrective actions are taken to confirm the consistency and the high-quality output.

How to Choose the Right CNC Machining Partner for

The important consideration in choosing the right advanced CNC machine service is by identifying the types of CNC machining and equipment specs that the partner offers. The key factors to consider are machine size and capacity, machine type, tooling, control systems and software, maintenance and the most important budget. Secondary operations like assembling, packaging or shipment also be checked.

Tuofa China Complex Precision Machining Capabilities

Tuofa CNC Machining is the leading provider of precision machining services in China. The variety of services it offers including:

- CNC machining: Tuofa is one best service that provides precision CNC machined parts.

- Custom OEM manufacturing: Tuofa offers custom OEM manufacturing services.

- 3D printing: Tuofa offers 3D printing services.

- Complex robotic parts: Tuofa has expanded its services to producing complex robotic parts

FAQ

Is Machining Hard Work?

Yes, machining can be hard work because it is a physically and mentally demanding task. It requires precision and high accuracy, and some tasks are repetitive which is stressful.

Is a Bicycle a Simple or Complex Machine?

A bicycle is a complex machines that do simple tasks. Because it is made up of several simple machines that are connected like lever, pulley, screws etc. to perform tasks

What is the Difference Between CNC Machining and Machining?

The major difference is CNC machining utilizes computer-aided software to automate the process, and the conventional machining process is a manual operation

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Drilling EDM Guide: Advantages and Disadvantages

Drilling EDM Guide: Advantages and Disadvantages